MODULAR SAFETY INTEGRATED CONTROLLER MOSAIC

8540780 • 30/03/2016 • Rev.26 103

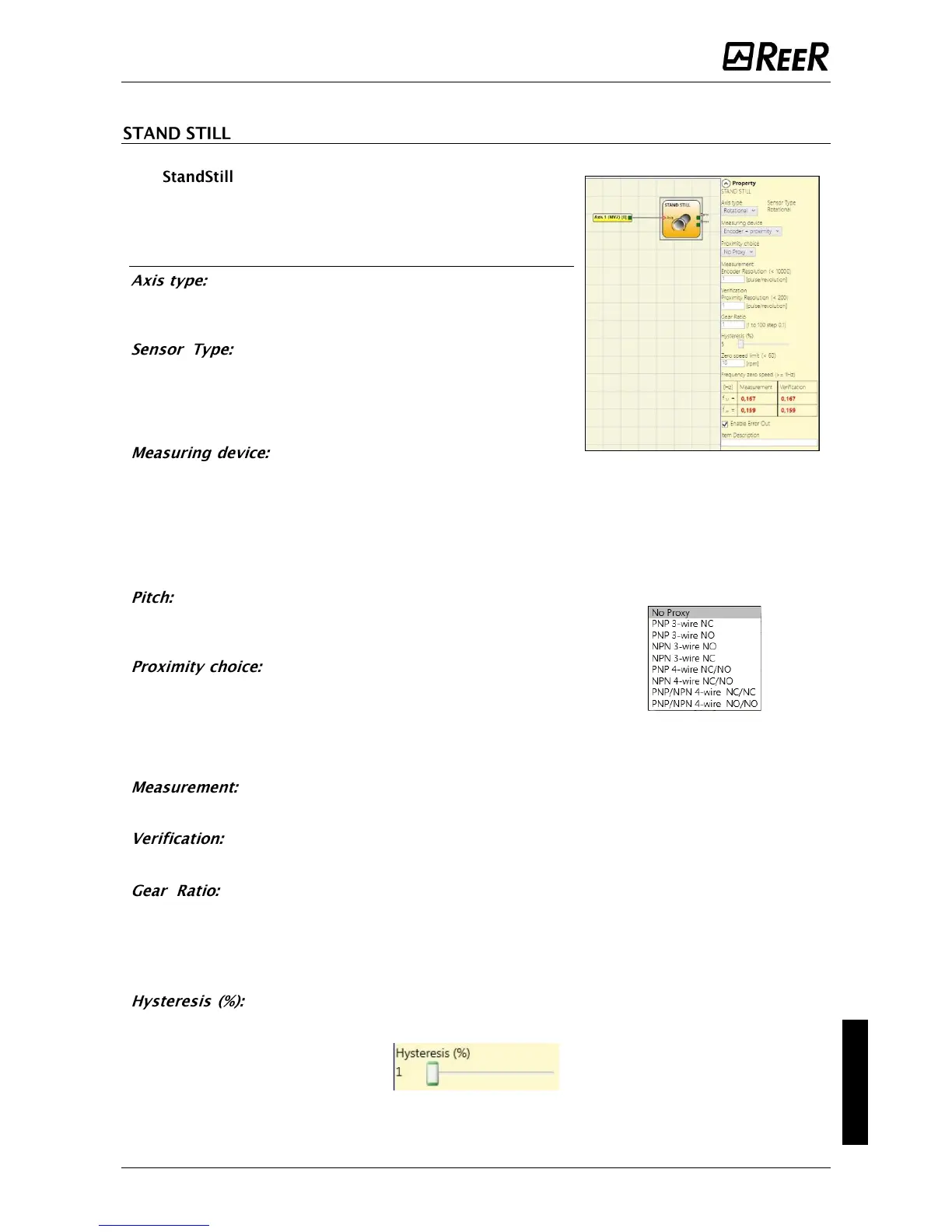

The function block monitors the speed of a device,

generating the Zero to 1 (TRUE) output when the speed is

lower than a selected value.

Parameters

It defines the type of axis controlled by the device.

It will be Linear in the case of a translation and will be Rotary

in the case of motion around an axis.

In the event that the previous parameter is

Linear, the Sensor Type defines the type of sensor connected

to the module inputs. It can be Rotary (e.g. shaft encoder) or

Linear (e.g. optical array). This choice allows to define the

following parameters.

It defines the type of sensor(s) used. The

possible choices are:

- Encoder

- Proximity

- Encoder+Proximity

- Proximity1+ Proximity2

- Encoder1+ Encoder2

If the Axis Type chosen was linear, this field allows you

to enter the sensor pitch to obtain a conversion between

sensor revolutions and distance travelled.

It allows you to choose the type of proximity

sensor from PNP, NPN, Normally Open (NA) and Normally Closed

(NC), with 3 or 4 wires.

(In order to ensure a Performance Level = PLe use a proximity

switch type PNP NO: ref. “Interleaved proximity -> page 25).

Enter in this field the number of pulses/revolution (in the case of rotary sensor)

or µm/pulse (linear sensor) relating to the sensor used

Enter in this field the number of pulses/revolution (in the case of rotary sensor) or

µm/pulse (linear sensor) relating to the second sensor used.

This parameter is active if there are two sensors on the selected axis. This

parameter allows you to enter the ratio between the two sensors. If both sensors are on the

same moving parts, the ratio will be 1 otherwise the number corresponding to the report must

be entered. E.g. there are an encoder and a proximity switch, and the latter is on a moving part

that (due to a gear reduction ratio) rotates at twice the speed of the encoder. Therefore, this

value must be set at 2.

It represents the percentage hysteresis value below which the speed change is

filtered. Enter a value other than 1 to avoid continuous switching as the input changes.

Loading...

Loading...