MODULAR SAFETY INTEGRATED CONTROLLER MOSAIC

106 8540780 • 30/03/2016 • Rev.26

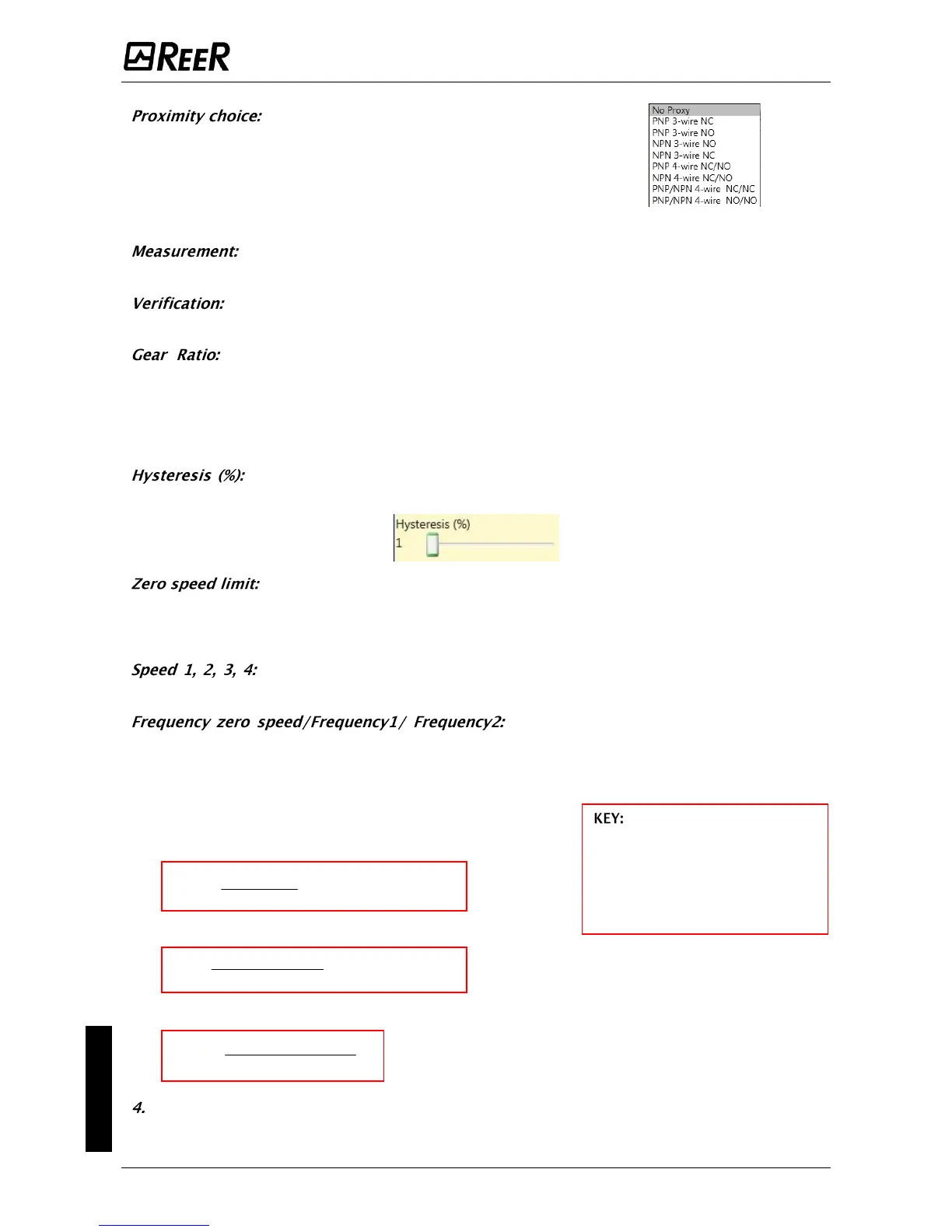

It allows you to choose the type of proximity

sensor from PNP, NPN, Normally Open (NA) and Normally Closed

(NC), with 3 or 4 wires.

(In order to ensure a Performance Level = PLe use a proximity

switch type PNP NO: ref. “Interleaved proximity -> page 26).

Enter in this field the number of pulses/revolution (in the case of rotary sensor)

or µm/pulse (linear sensor) relating to the sensor used

Enter in this field the number of pulses/revolution (in the case of rotary sensor) or

µm/pulse (linear sensor) relating to the second sensor used.

This parameter is active if there are two sensors on the selected axis. This

parameter allows you to enter the ratio between the two sensors. If both sensors are on the

same moving parts, the ratio will be 1 otherwise the number corresponding to the report must

be entered. E.g. there are an encoder and a proximity switch, and the latter is on a moving part

that (due to a gear reduction ratio) rotates at twice the speed of the encoder. Therefore, this

value must be set at 2.

It represents the percentage hysteresis value below which the speed change is

filtered. Enter a value other than 1 to avoid continuous switching as the input changes.

Enter in this field the maximum speed value above which the output of the function block (ZERO)

will be 0 (FALSE). If the measured speed is less than the set value, the output (ZERO) of the

function block will be 1 (TRUE).

Enter in this field the maximum speed value above which the function block

output (OVER) will be 0 (FALSE). If the measured speed is less than the set value, the function

block output (OVER) will be 1 (TRUE).

It shows

the maximum calculated frequency values fM and fm

(decreased by the hysteresis set). If the displayed value is

GREEN, the calculation of frequency gave a positive result.

If the displayed value is RED, it is necessary to change the

parameters given in the following formulas.

1. Rotary axis, rotary sensor. The frequency obtained is:

v][pulses/resolutionRe

60

[rev/min]rpm

[Hz]f

2. Linear axis, rotary sensor. The frequency obtained is:

v][pulses/reRe

[mm/rev]*60

1000*[m/min]

[Hz] solution

pitch

speed

f

3. Linear axis, linear sensor. The frequency obtained is:

[µm/pulse]solutionRe

1000*[mm/s]speed

[Hz]f

Hysteresis. To be changed only if: fM=green; fm=red

f = frequency

Rpm = rotational speed

Resolution = measurement

Speed = linear speed

Pitch = sensor pitch

Loading...

Loading...