V 01/2016

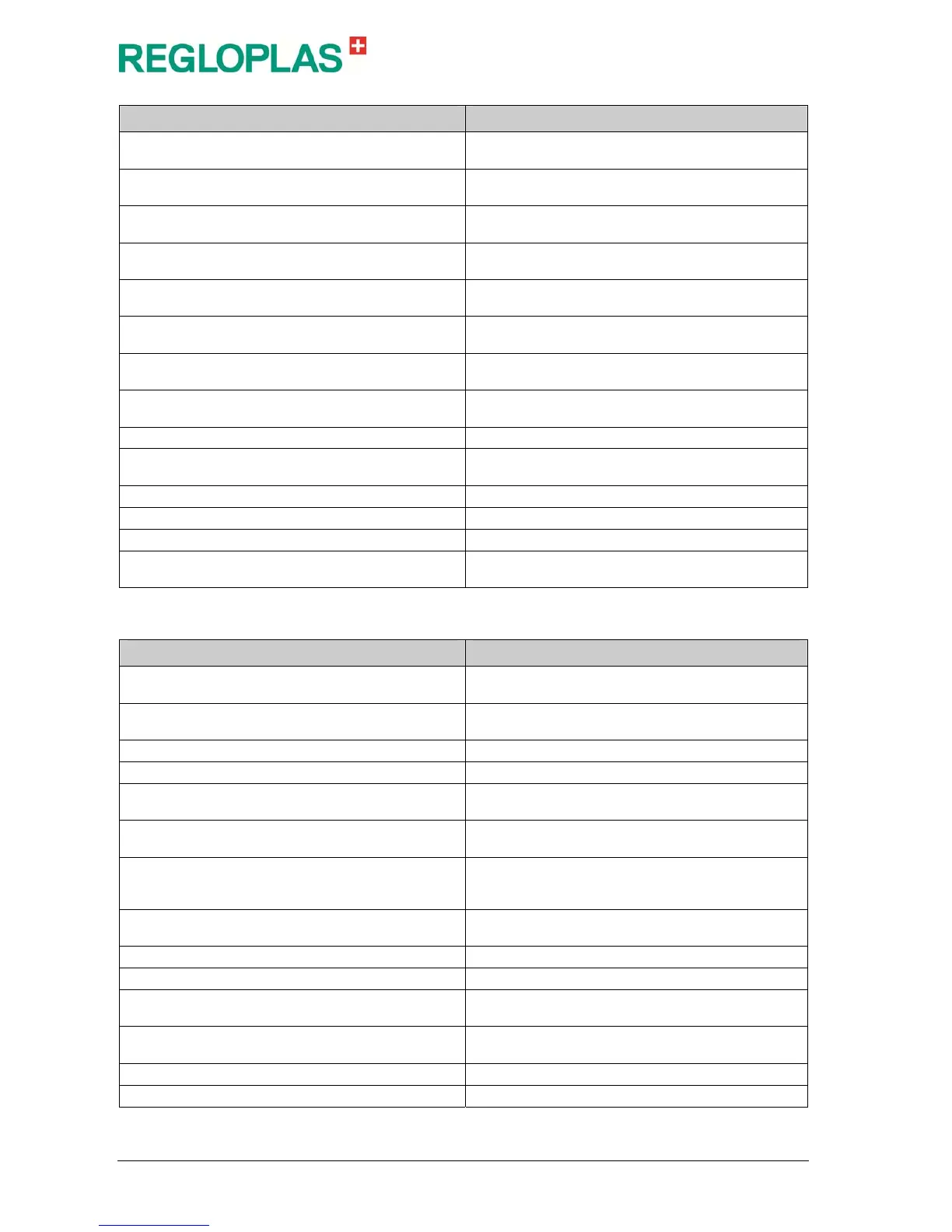

58 Fault Rectification RT100 Control System

Error message Rectification

Deviation set-point value/outlet underrun

Adjust the outlet temperature and acknowledge the

fault

Deviation set-point value/outlet exceeded

Adjust the outlet temperature and acknowledge the

fault

Deviation set-point value/external underrun

Adjust the external temperature and acknowledge the

fault or error

Deviation set-point value/external exceeded

Adjust the external temperature and acknowledge the

fault or error

Deviation set-point value/inlet underrun

Adjust the inlet temperature and acknowledge the

fault

Deviation set-point value/inlet exceeded

Adjust the inlet temperature and acknowledge the

fault

Deviation outlet/inlet underrun

Adjust the inlet temperature and acknowledge the

fault

Deviation outlet/inlet exceeded

Adjust the inlet temperature and acknowledge the

fault

Level 2 underrun Refill heat transfer medium

Pressure balance not possible

Check water inflow pipe and water pressure (min. 2

bar)

Leak stop not possible Reduce the temperature

Leak stop not allowed Unit is not allowed for leak stop

Suction not possible Switch the unit to normal operation mode

SSR error

SSR DC with auxiliary contact has activated. Check

SSR

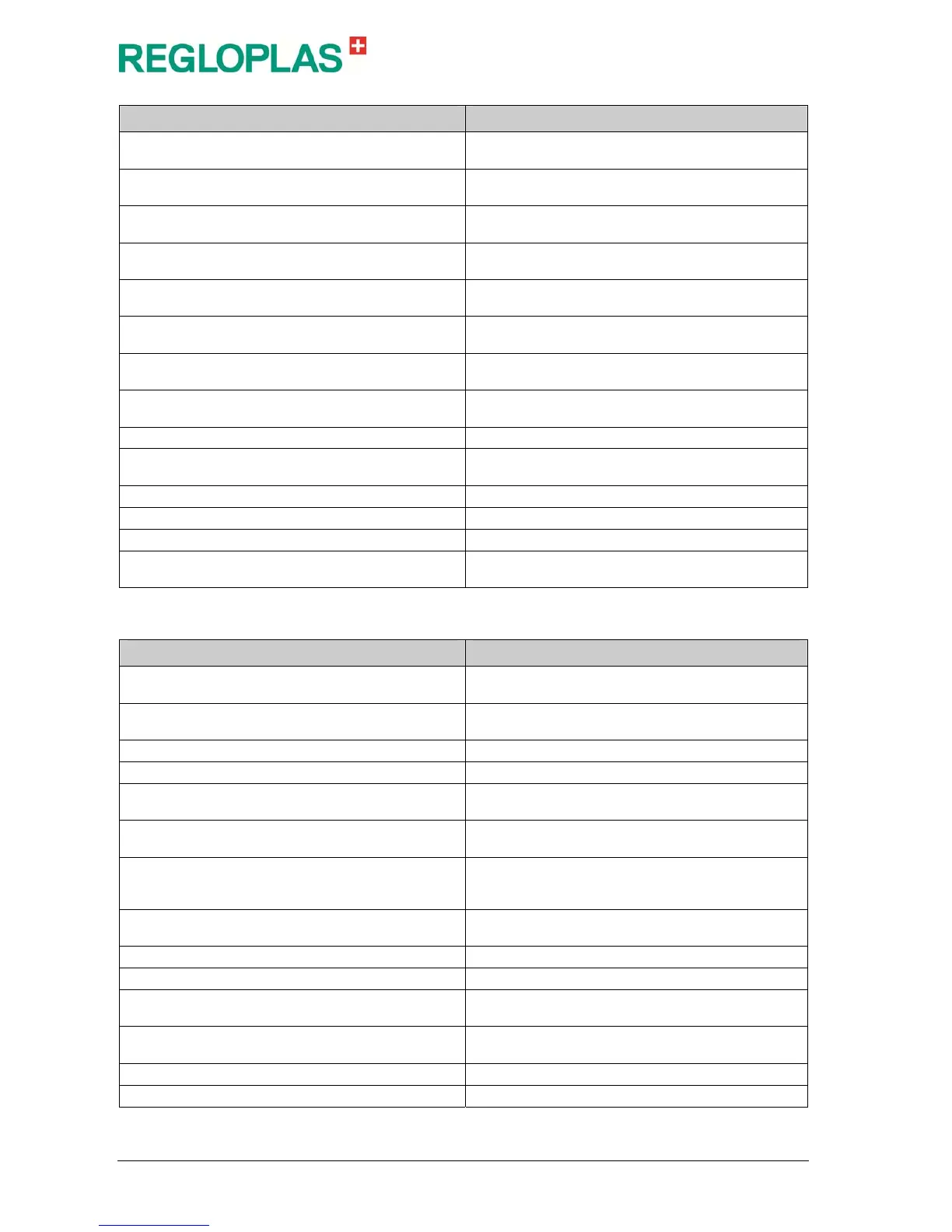

Alarms

Error message Rectification

External set-point signal disconnected or not available

Connect the external set-point value signal (optionally

check control system)

Maximal operating time boost pump exceeded

Check hose connections to the consumer, fix the

leakages

Flow monitor is activated Check outlet pressure (min. 0,7 bar must be available)

Min. pump pressure underrun Check outlet pressure

Min. flow rate underrun

Check min. flow rate (the specified min. flow rate must

be available)

Flow rate deviation too high

Large variation in the flow (there may be a leak in the

circuit)

Max. temperature exceeded

Max. temperature Sn2 exceeded

Max. temperature Sn3 exceeded

Max. heat transfer medium temperature may not ex-

ceed the die max. device temperature (optionally

check the consumer temperature)

Heating thermostat is activated

Temperature control unit has become too hot - let it

cool down and determine the cause

Heating current monitoring is activated Check heating element(s) and replace, if necessary

Direction of rotation cannot be changed ---

Motor current underrun

Check pump/pump motor (with ohmmeter) and re-

place, if necessary

Motor current exceeded

Check pump/pump motor (with ohmmeter) and re-

place, if necessary

Phase sequence failure Correct the phase sequence (interchange 2 phases)

Phase sequence unidentified Switch off phase sequence monitoring

Loading...

Loading...