11A-174

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K4M

11A

a Fit:

-a new cylinder head gasket,

-the cylinder head equipped with new bolts on the

cylinder block.

a Check that the centring dowel is present on the cy-

linder block.

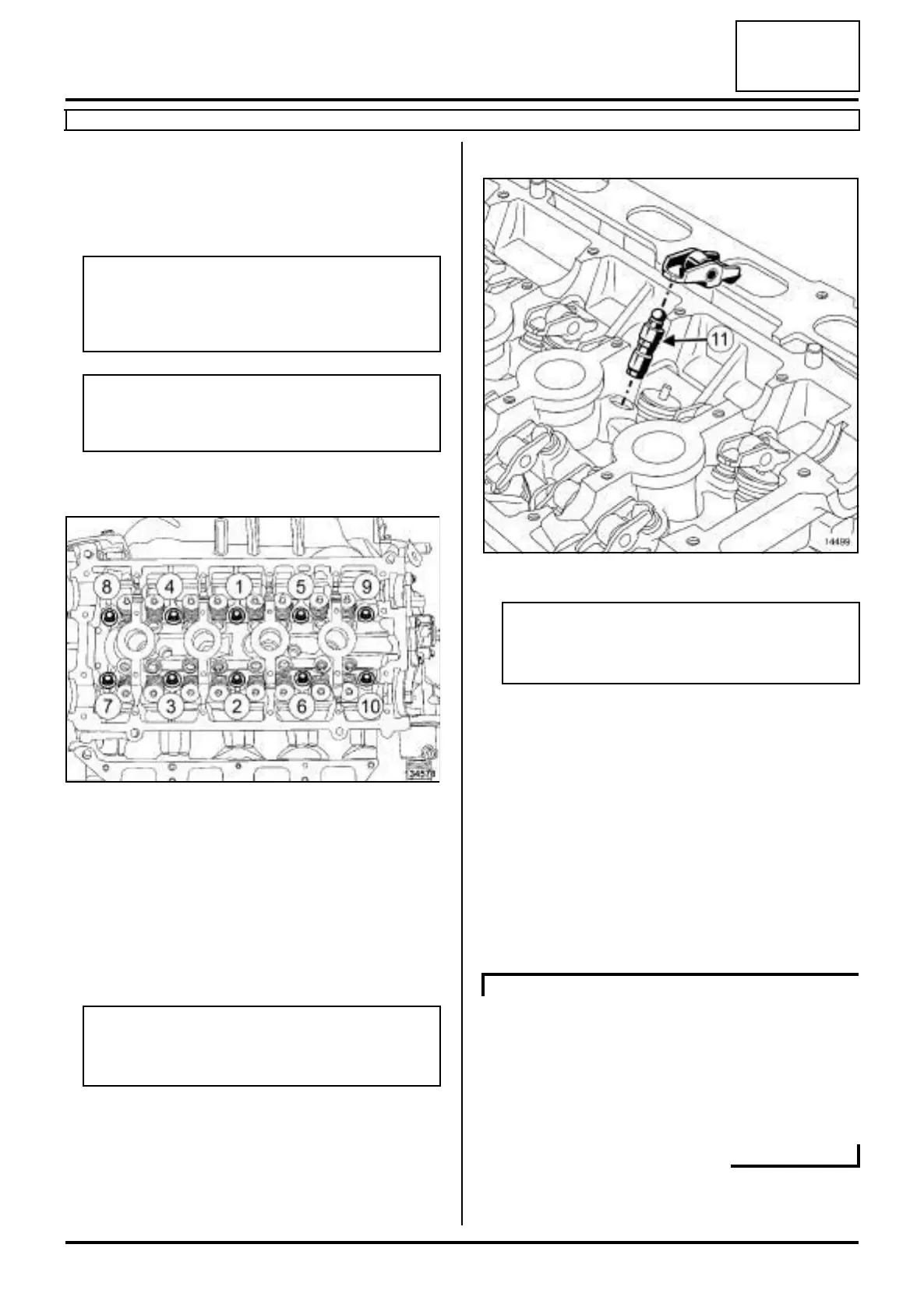

a Without tightening, fit the cylinder head bolts in or-

der.

a Pretighten in order and to torque the new cylinder

head bolts (initial torque) (20 N.m).

a Check that all new cylinder head bolts are tightened

to the correct torque 20 N.m.

a Angle tighten in order the new cylinder head bolts

(240˚ ±±

±±

6˚).

III - FINAL OPERATION

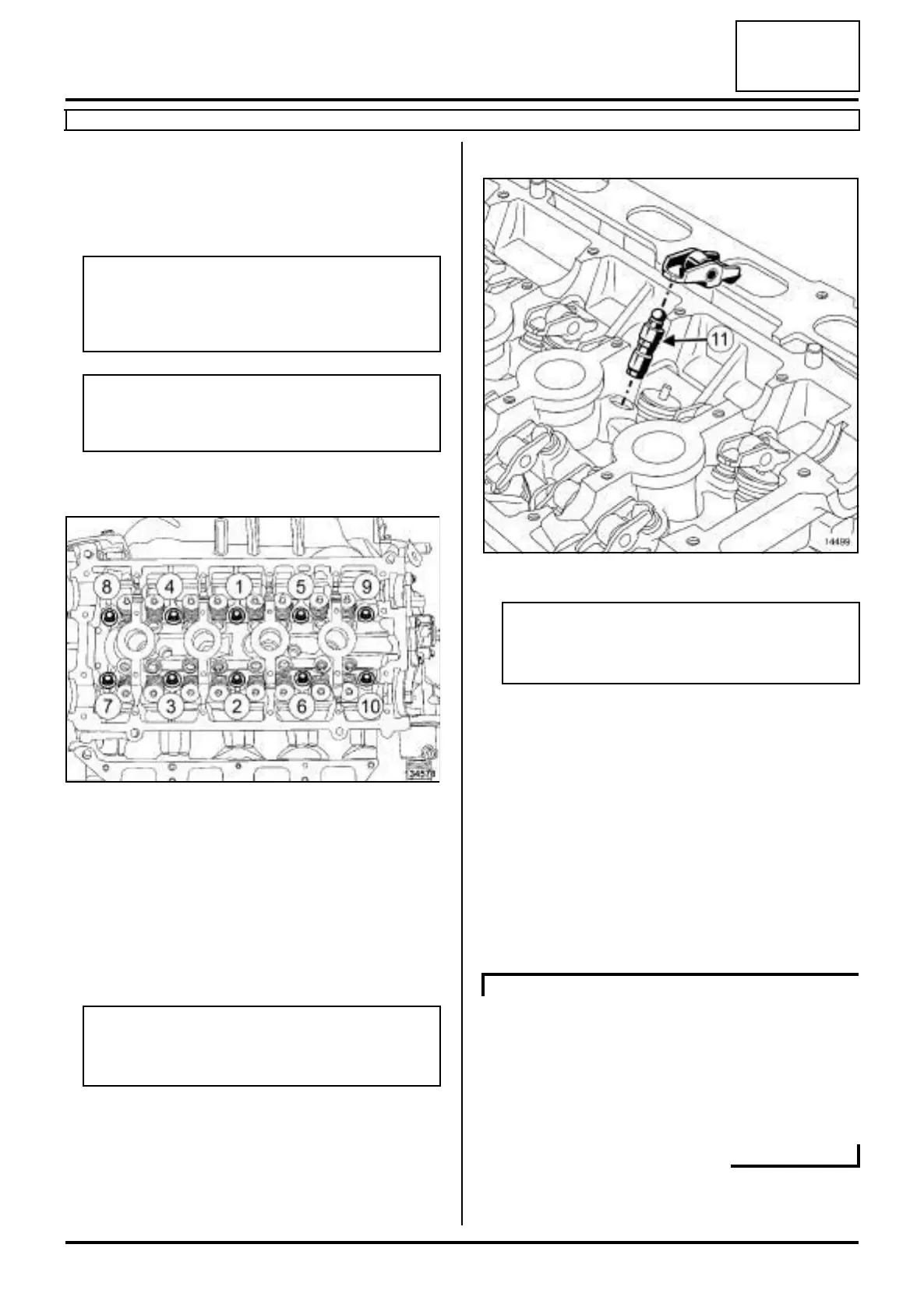

a

a Reprime the hydraulic tappets (hydraulic tappets

may empty after a long down time).

a To check if repriming is necessary, press the top of

the tappet (11) with your thumb.

a If the tappet piston sinks, dip the tappet in a contai-

ner filled with diesel.

a Press on the top of the tappet to expel air bubbles.

a Refit:

- the hydraulic thrust bearings,

- the valve rockers.

a Fit the engine wiring channel.

a Refit the bolts of the engine wiring channel.

a Connect the crankshaft position sensor connector.

a Clip on the wiring of the injector holder shim.

a Connect:

- the upstream oxygen sensor connector,

WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

WARNING

Do not oil the new bolts. Be sure to oil bolts

being reused.

134578

Note:

Do not retighten the cylinder head bolts after

applying this procedure.

14499

Note:

Because this engine is equipped with hydraulic

tappets, there is no valve clearance adjustment.

K4M, and 848

Loading...

Loading...