13B-47

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K, and 834

13B

-the fuel supply pipe union protection bracket,

-the high pressure pump

REFITTING

I - REFITTING PREPARATION OPERATION

a Always replace the seal on the intermediate air pipe

between the turbocharger and the intercooler.

If replacing the high pressure pump

a

a

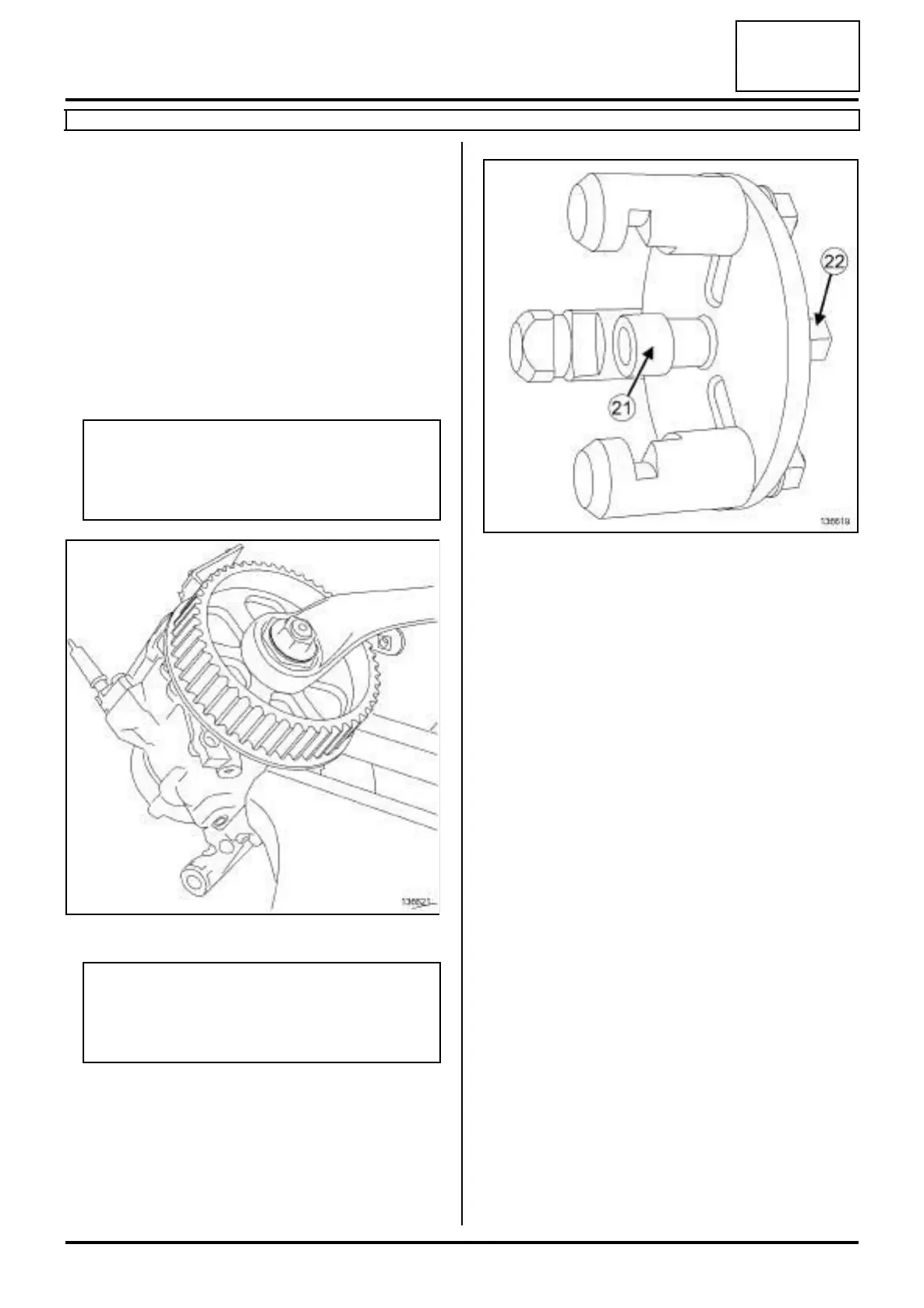

a Secure the high pressure pump in a vice with jaws,

by the lower bolt hole on the high pressure pump

pulley side.

a Immobilise the high pressure pump pulley using a

offset spanner.

a Remove the nut from the high-pressure pump pul-

ley.

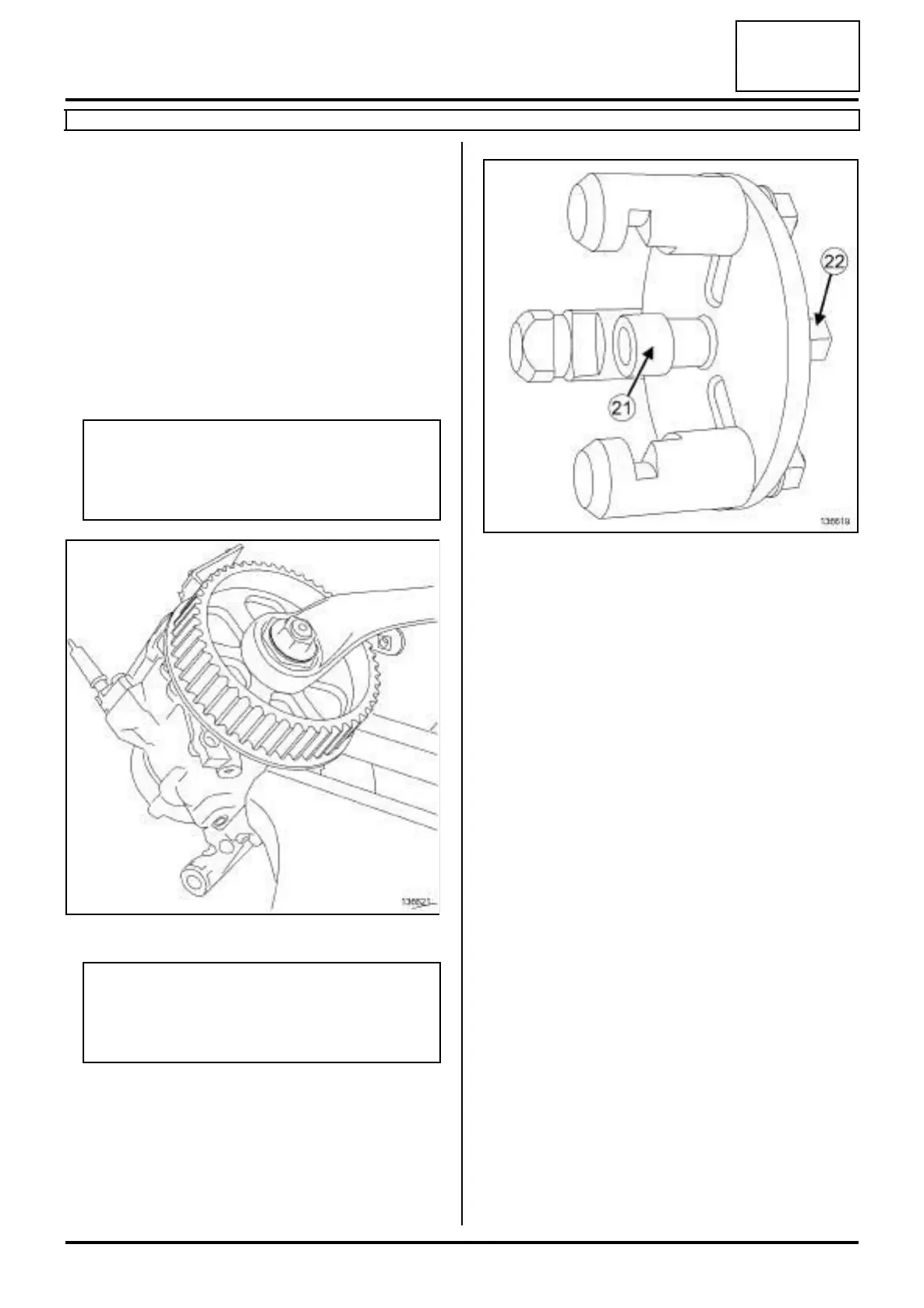

a Remove the end piece (21) of the tool (Mot. 1525)

by unscrewing the bolt (22) .

a Protect the contact areas between the tool (Mot.

1525) equipped with the tool (Mot. 1525-02) and the

high pressure pump pulley.

a Fit the tool (Mot. 1525) equipped with the tool (Mot.

1525-02) to remove the high pressure pump pulley.

a Remove the high pressure pump pulley.

a A damaged high pressure pump pulley must always

be replaced.

a Remove the old high pressure pump from the vice.

a Place the new high pressure pump in a vice with

jaws, by the lower bolt hole on the high pressure

pump pulley side.

a Refit the high pressure pump pulley.

a Immobilise the high pressure pulley using a offset

spanner.

a Torque tighten the high pressure pump pulley nut

(70 N.m).

Note:

If replacing a high pressure pump, only remove

the new high pressure pump from its original

packaging when it is about to be fitted.

136621

Note:

If the high pressure pump is replaced, retain the

high pressure pump pulley and refit it to the new

high pressure pump.

136619

Loading...

Loading...