13B-81

DIESEL INJECTION

High-pressure pipe between the pump and rail: Removal - Refitting

K9K, and 832

13B

-the injector rail protector bolt (18) ,

-the injector rail protector.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

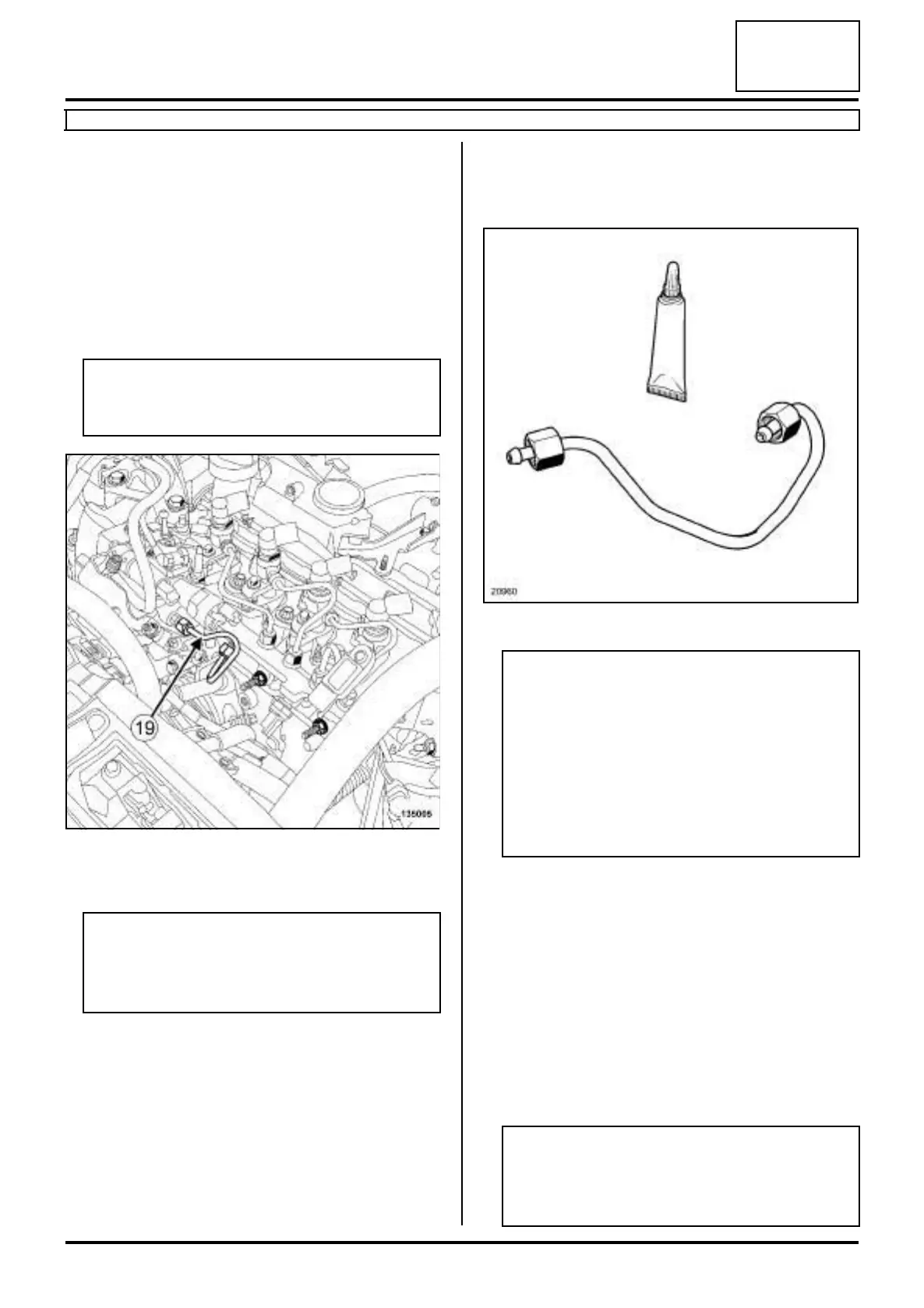

a Clean the unions of the high pressure pipe between

the high pressure pump and the injector rail (see

13B, Diesel injection, Diesel injection: Precau-

tions for repair, page 13B-1) .

a Remove the high pressure pipe between the high

pressure pump and the injector rail (19) .

a Place a suitable blanking plug on:

-the high pressure pump opening,

-the injector rail opening.

REFITTING

I - REFITTING PREPARATION OPERATION

a

a parts always to be replaced: High-pressure pipe

between the pump and rail (11,05,03,02).

II - REFITTING OPERATION FOR PART

CONCERNED

a Remove the blanking plugs from:

- the high pressure pump opening,

- the injector rail opening.

a Fit the new high pressure pipe between the injector

rail and the high pressure pump.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

135005

Note:

It is essential to use a spanner to hold the high

pressure pump intermediate union when loose-

ning the high pressure pipe.

20960

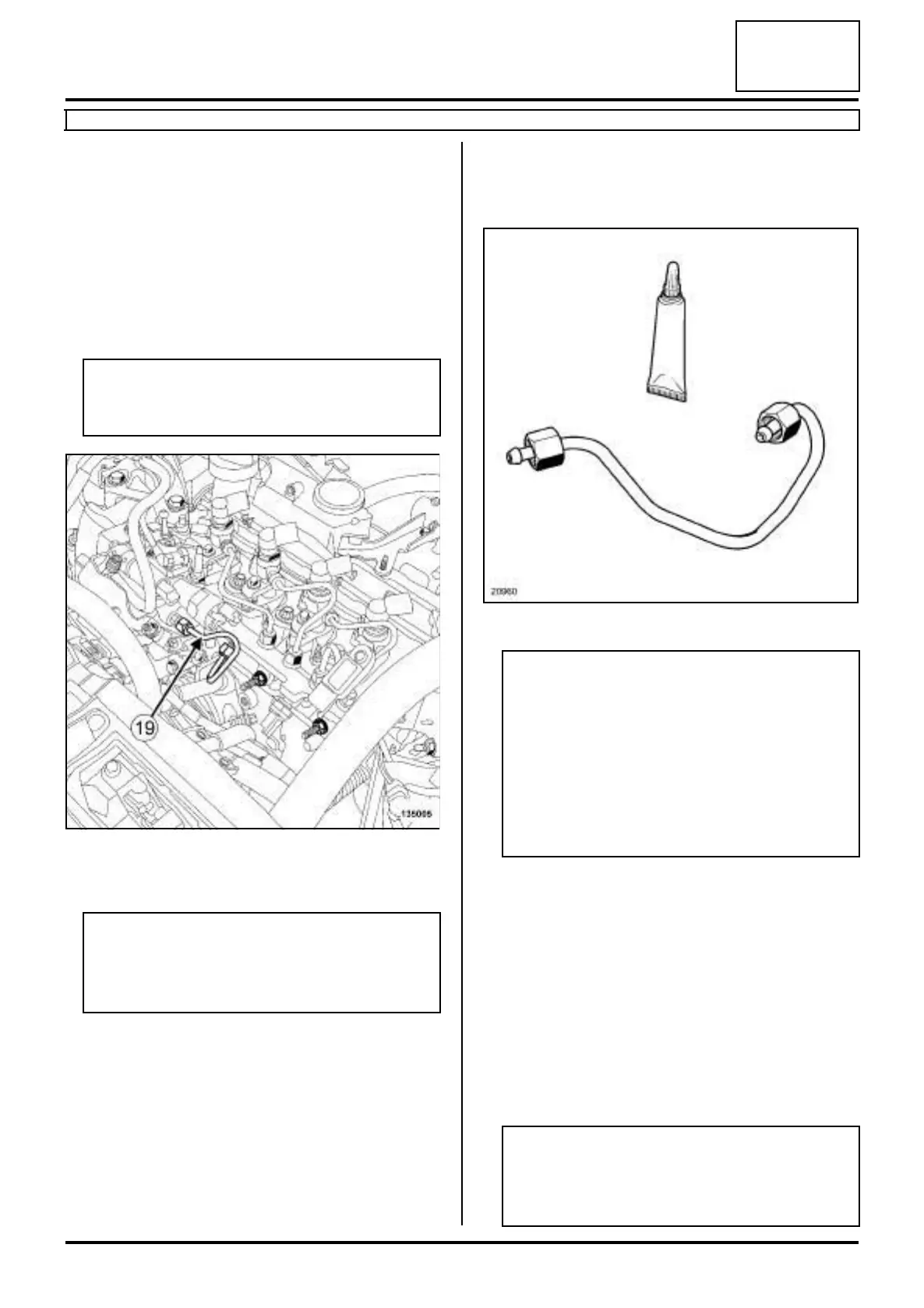

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator, as these high pressure

pipes are self-lubricating.

Note:

If the set of new pipes does not contain an appli-

cator, do not lubricate the threads of the high

pressure pipe (as they are self-lubricating pipes).

Loading...

Loading...