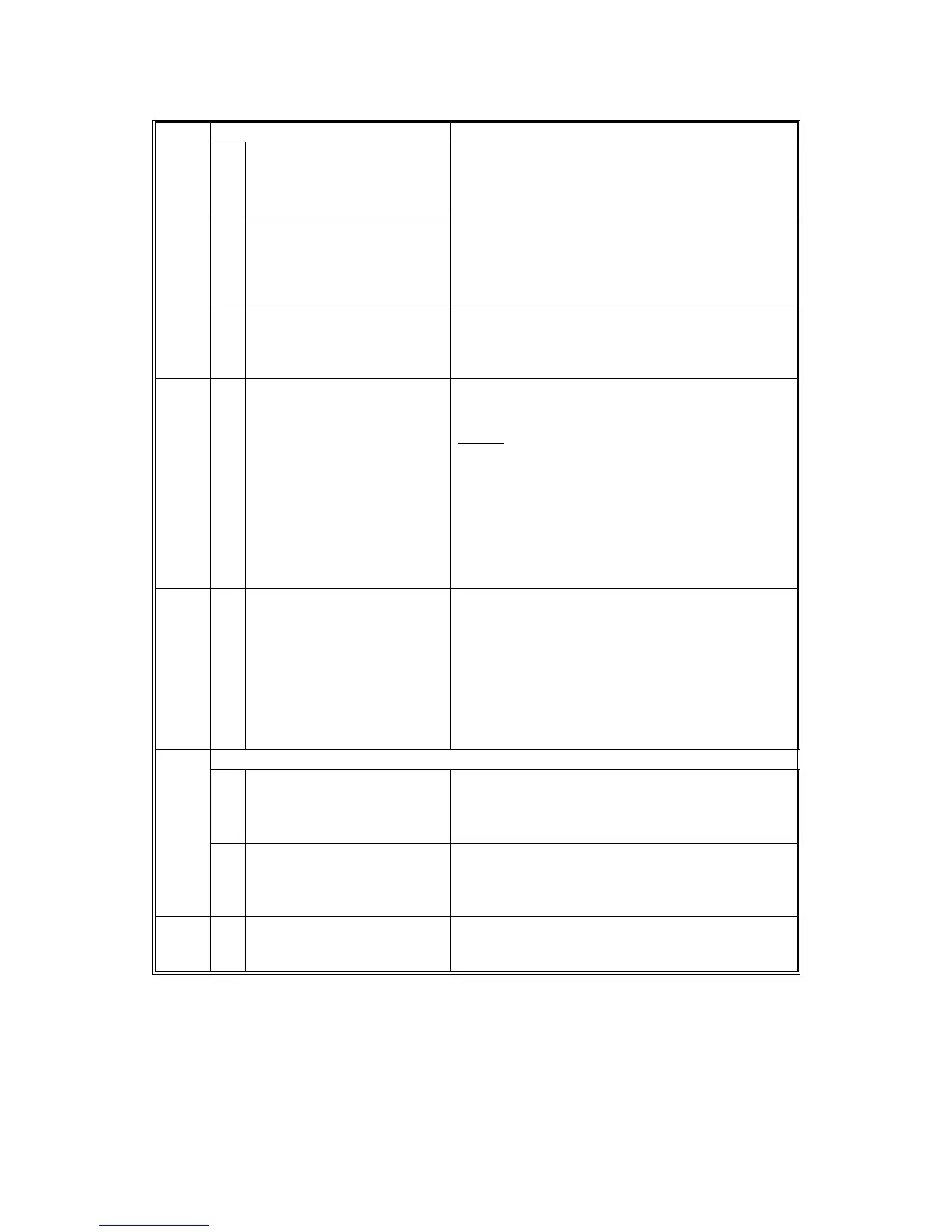

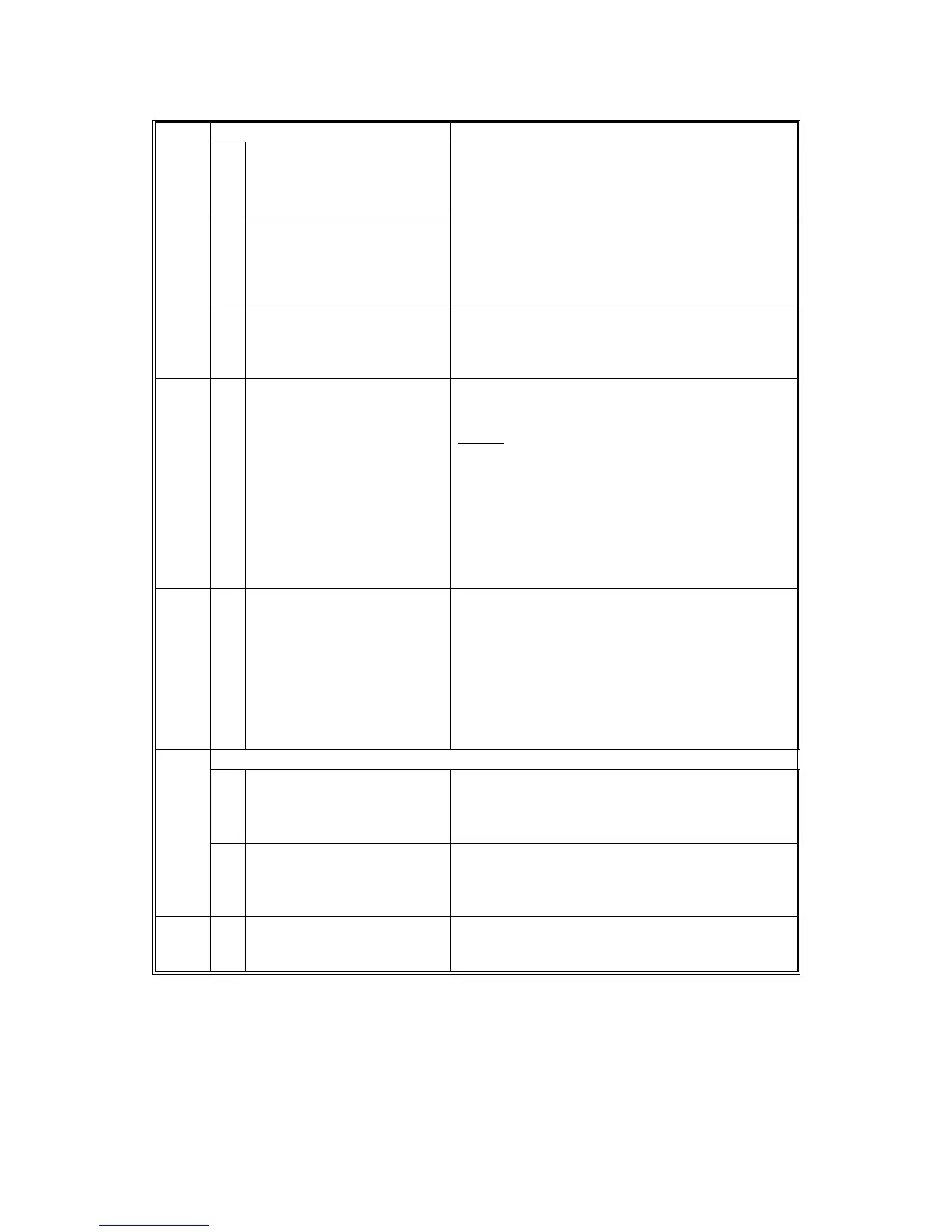

PRINTER ENGINE SERVICE MODE

G065 5-12 SM

SP2 Mode Number Function and [Setting]

06 LD Unit Position Displays the current LD unit position (number of

pulses from home position). If this is different

from the value of SP2109-01 or SP2109-02, LD

unit positioning has failed.

07 Pitch Change Count Displays how many times the LD unit position

has been changed (how many times the

resolution has changed.)

When the laser beam pitch adjustment is done,

this counter is reset to zero.

2109*

08 Beam Pitch Data Reset

Resets the values of SP2109-06 and SP2109-

07.

After replacing the LD unit, this SP mode must

be performed. See section 3.9.5.

2110 01 Test Mode dpi Sets the scanning resolution (dpi).

[See below / 8 / 0 ~ 18]

Range 0: 400 x 400 dpi

1: 391 x 406 dpi

2: 406 x 391 dpi

4: 300 x 300 dpi

8: 600 x 600 dpi

15: 439 x 430 dpi

16: 476 x 476 dpi

17: 483 x 465 dpi

18: 465 x 483 dpi

2112 01 Polygon Motor Off Timer Input the time that the polygon motor is to switch

off after the printer has remained idle for the

specified time and entered the standby mode.

If set to zero, the polygon motor never switches

off in standby mode. However, if the machine

enters the energy saver mode, the polygon

motor will ignore the zero setting and switch

itself off.

[0~60 s / 10 s / 5 s step]

Development Bias

01 Image Development Bias Adjusts the development bias for printing.

Use as a temporary measure to correct faint

images printed with an aging drum.

[–200 ~ –700 / 540 V / 10 V step]

2201*

02 ID Sensor Pattern Adjusts the development bias for the ID sensor

pattern for V

SP

(ID sensor output after reading

the ID sensor pattern).

[–200 ~ –700 / 380 V / 10 V step]

2207 01 Forced Toner Supply Forces the toner bottle to supply toner at 1-

second intervals for up to 30 seconds. To start,

press #(Enter).

Loading...

Loading...