Reference Manual

00809-0100-4004, Rev BA

August 2010

5-15

Rosemount 8800D

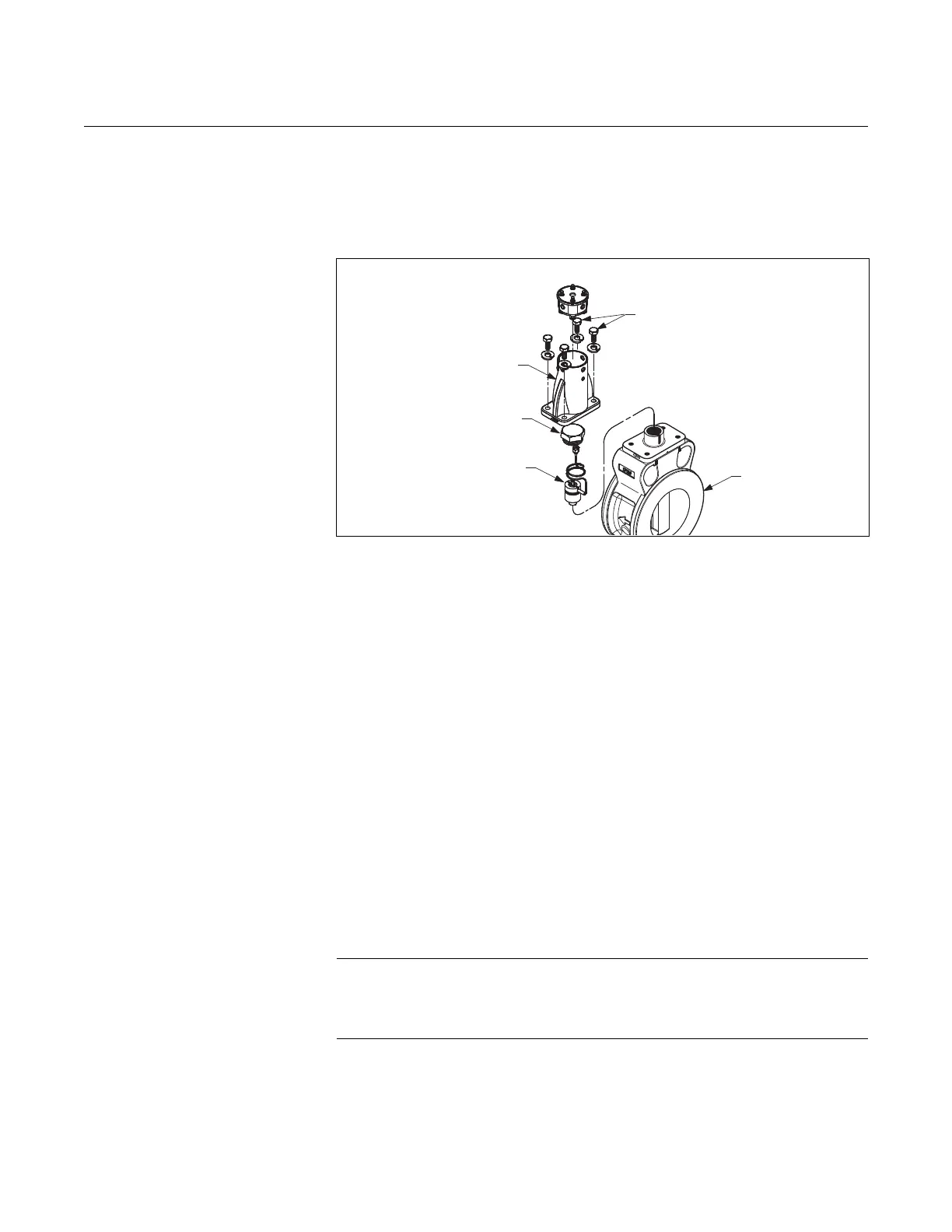

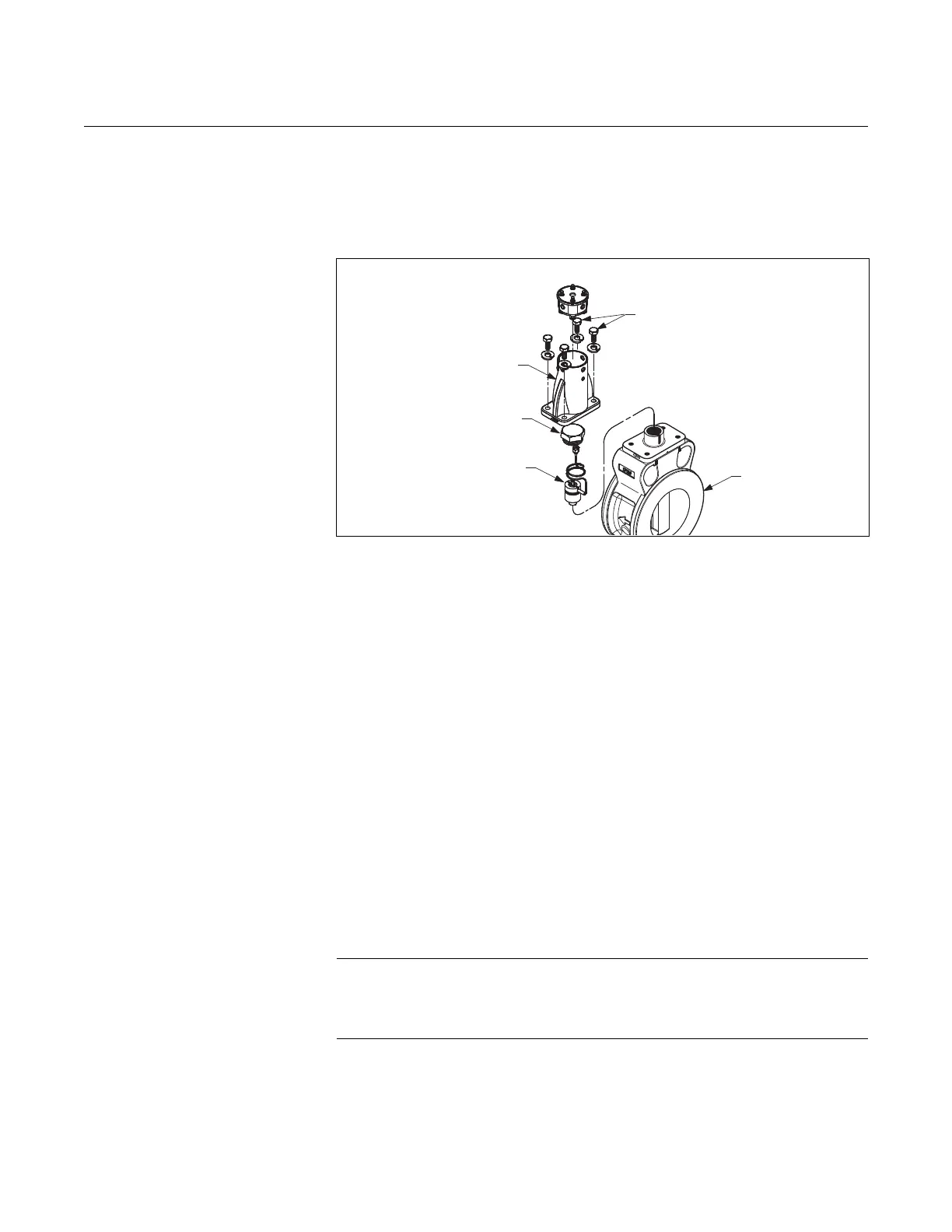

Removable Support Tube

8. Loosen the four support tube anchor bolts with a

7

/16-in. open end

wrench. (See “”Removable Support Tube Assembly” Figure 5-8)

9. Remove the support tube.

10. Loosen and remove the sensor nut from the sensor cavity with a

1

1

/8-in. (28-mm) open end wrench. (Use a

3

/4-in. (19-mm) open end

wrench for 3- and 4-in. [80 and 100 mm] SST wafers.)

11. Lift the sensor from the sensor cavity. Be very careful to lift the sensor

straight up. Do not rock, twist, or tilt the sensor during removal; this

will damage the engagement diaphragm.

12. Tighten the valve to insure it is closed after the new Vortex sensor is

installed. It is recommended that the nut be torqued to 50 in-lbs (5.7

N-m). Over tightening the valve nut could compromise its ability to

seal.

Cleaning the Sealing Surface

Before installing a sensor in the meter body, clean the sealing surface by

completing the following procedure. The metal o-ring on the sensor is used to

seal the sensor cavity in the event that process fluid should corrode through

the meter body and enter the sensor cavity. Be sure not to scratch or

otherwise damage any part of the sensor, sensor cavity, or sensor nut

threads. Damage to these parts may require replacement of the sensor or

meter body, or may render the flowmeter dangerous.

NOTE

If you are installing a sensor that has been used before, clean the metal o-ring

on the sensor using the procedure below. If you are installing a newly

purchased sensor, cleaning the o-ring is not necessary.

1. Use a suction or compressed air device to remove any loose particles

from the sealing surface and other adjacent areas in the sensor

cavity.

Figure 5-8. Removable Support Tube Assembly

Removable

Support Tube

Sensor Nut

Sensor

Anchor Bolts

Meter Body

Loading...

Loading...