BRP-Rotax

MAINTENANCE MANUAL

CONSUMABLE MATERIALS

General note

ATTENTION

Use only the specified or technically equivalent materials from BRP-Rotax for all

maintenance work. When handling chemicals, comply with all the customary reg-

ulations and specifications of the producer, including the expiry date and instruc-

tions of use.

NNOOTTEE

To some extent product descriptions deviate in spite of equivalent technical prop-

erties, i.e.: LOCTITE 243 and LOCTITE 243. If necessary contact the manufac-

turer concerning the comparability. In some cases information can be obtained

from the local authorized distributors and service partners for ROTAX® engines.

NNOOTTEE

Respect the manufacturers instruction concerning the curing time and the expiry

date of the particular surface sealing compound.

The materials specified have been tested for a long time and are suitable for all operating

conditions indicated by the manufacturer.

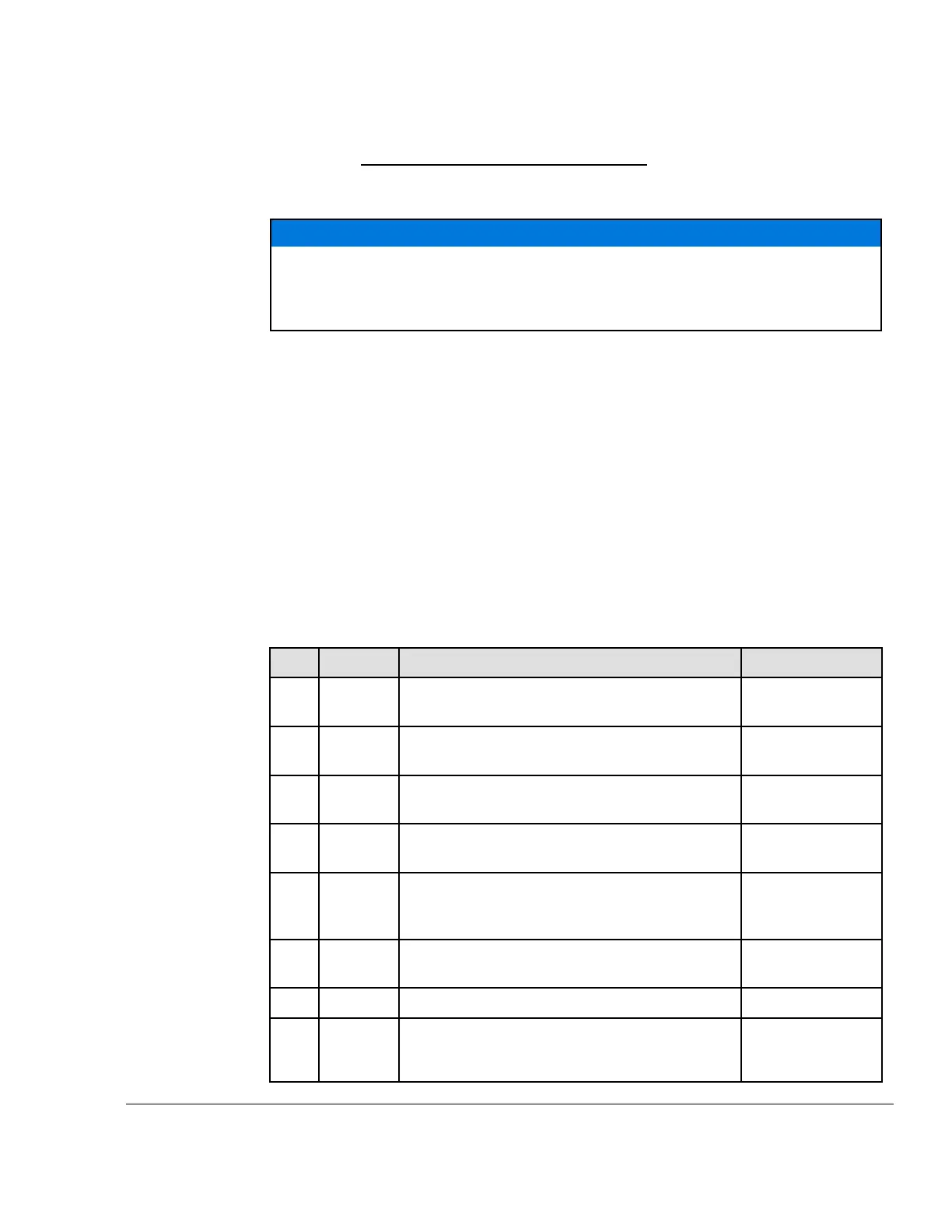

No.

part no. Description, Application Qty.

B 897651 LOCTITE 243,blue

medium-duty screw securing agent

10 ml

(0.003 gal (US))

C

899788

LOCTITE 648 green,

high strength screw securing agent

5 ml

(0.001 gal (US))

E 297434 LOCTITE Anti-Seize,

for the prevention of fretting corrosion

50 ml

(0.013 gal (US))

F

xxx

LOCTITE 7063

For degreasing and cleaning surfaces

AR

H 897870 Filter oil

for optimum filter efficiency and protection

against moisture

14.8 ml

(0.004 gal (US))

I 897330 Lithium-base grease

Electrical insolating

250 g

(0.55 lb)

O

297997

Engine oil Aeroshell Sport Plus 4

AR

P 899791 LOCTITE 5910 black,

surface sealing compound, can be used instead

LOCTITE 574 and LOCTITE 518

50 ml

(0.013 gal (US))

Effectivity: 915 i A Series

Edition 0/Rev. 0

05–00–00

Page 7

December 01 2017

Loading...

Loading...