Section 6 - Service

72 SCHWARZE HYPERVAC HV-18 revised 11/18

6.1 Oil Levels and Lubrication

Auxiliary Engine Oil

Refer to your auxiliary engine Owner’s Manual for

the manufacturer’s suggested oil type and oil change

schedule. To drain the engine oil pan, use the engine oil

drain hose. This hose, which resembles the hydraulic

hoses, runs from the center of the oil pan, out the right

side of the engine skid and is usually looped around to the

front of the engine skid for storage. By unscrewing and

removing the JIC plug in the end of the hose, the oil may

be drained into a container. Be sure to dispose of the used

oil properly, recycling it if possible.

Normal engine oil pressure should be 380 ± 103kPa (3.80

bar ± 1.03 bar; 55 ± 15 psi) at rated full-load speed (1800

- 2500 rpm) with oil at normal operating temperature of

105°C (220°F).

Important: If the gauge needle does not rise above the

minimum oil-pressure specication of 103 kPa (1.03 bar;

15 psi) within 5 seconds, stop the engine and notify your

supervisor. Auxiliary Engine Cooling System

Auxiliary Engine Cooling System

Refer to your auxiliary engine Owner’s Manual for cooling

system care and maintenance. When replacing your

engine’s coolant, be sure to dispose of the old coolant

properly.

Normal engine coolant temperature range is 82° - 94°C

(180°-202°F).

Important: Do not place the engine under full load until it

is properly warmed up.

Hydraulic System

The hydraulic oil level should be maintained such that it is

kept at the full mark as measured with the hopper down,

brooms up and the pickup head in the up position. Check

by using the sight level gauge, which is located on the left

side of the reservoir. Change the hydraulic oil and lter

after the rst 500 hours of operation, then every 2000

hours thereafter.

If the hydraulic uid becomes cloudy, water has

contaminated the system and the hydraulic uid needs

to be changed (after determining the source of the water

contamination and correcting it). If the sweeping unit is

operated in particularly dusty conditions, the hydraulic

lters will need to be changed more often.

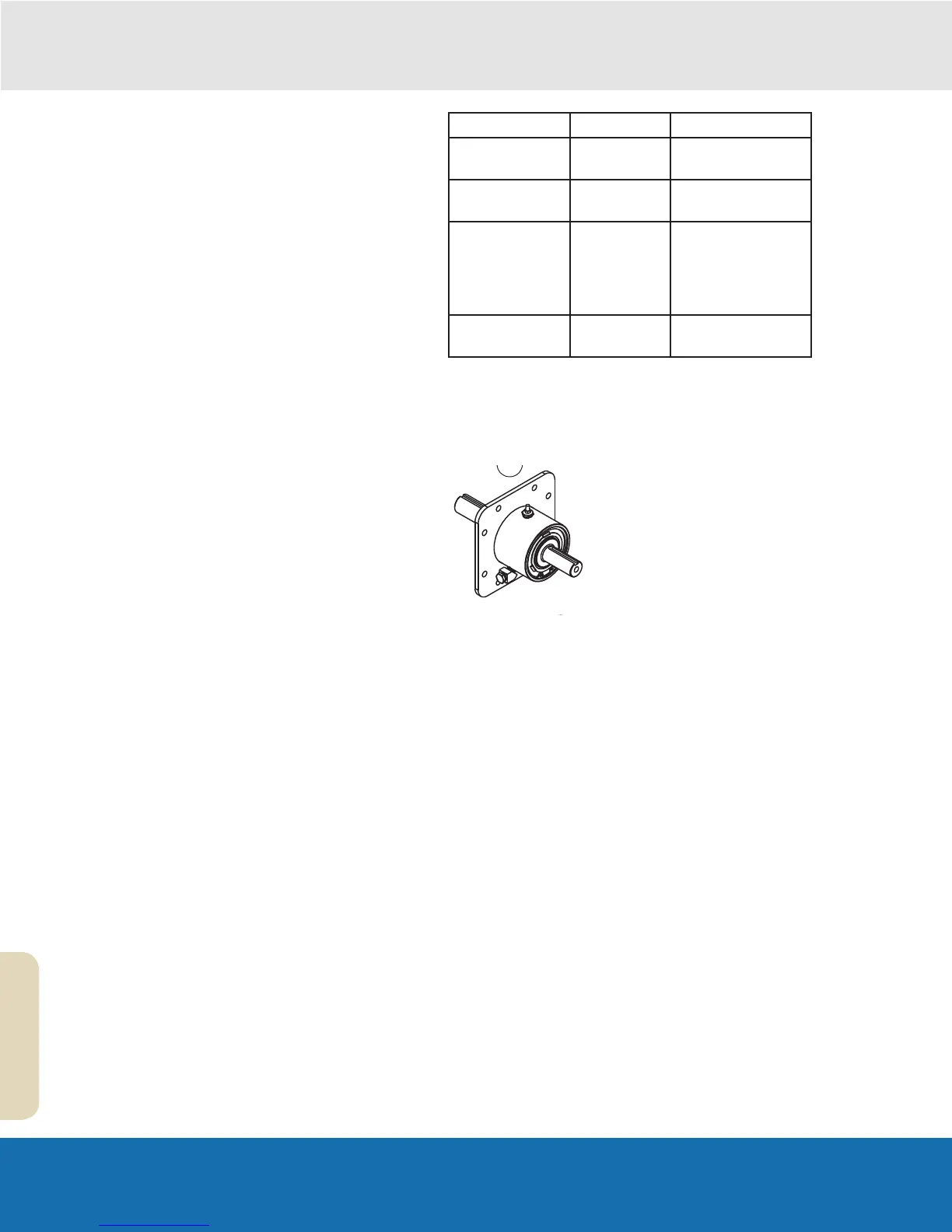

Lubrication Schedule

Item Frequency Lubrication

Dump Door

Hinges

Monthly Grease with lithium-

based grease.

Hopper/Frame

Hinge

Monthly Grease with lithium-

based grease.

Fan Seal, Intake

Seal, and Rear

Door Seal

As Required Lubricate with a

rubber protector or

grease to prevent

drying and loss of

resilience.

Leaf Bleader

Door

Monthly Grease with lithium-

based grease.

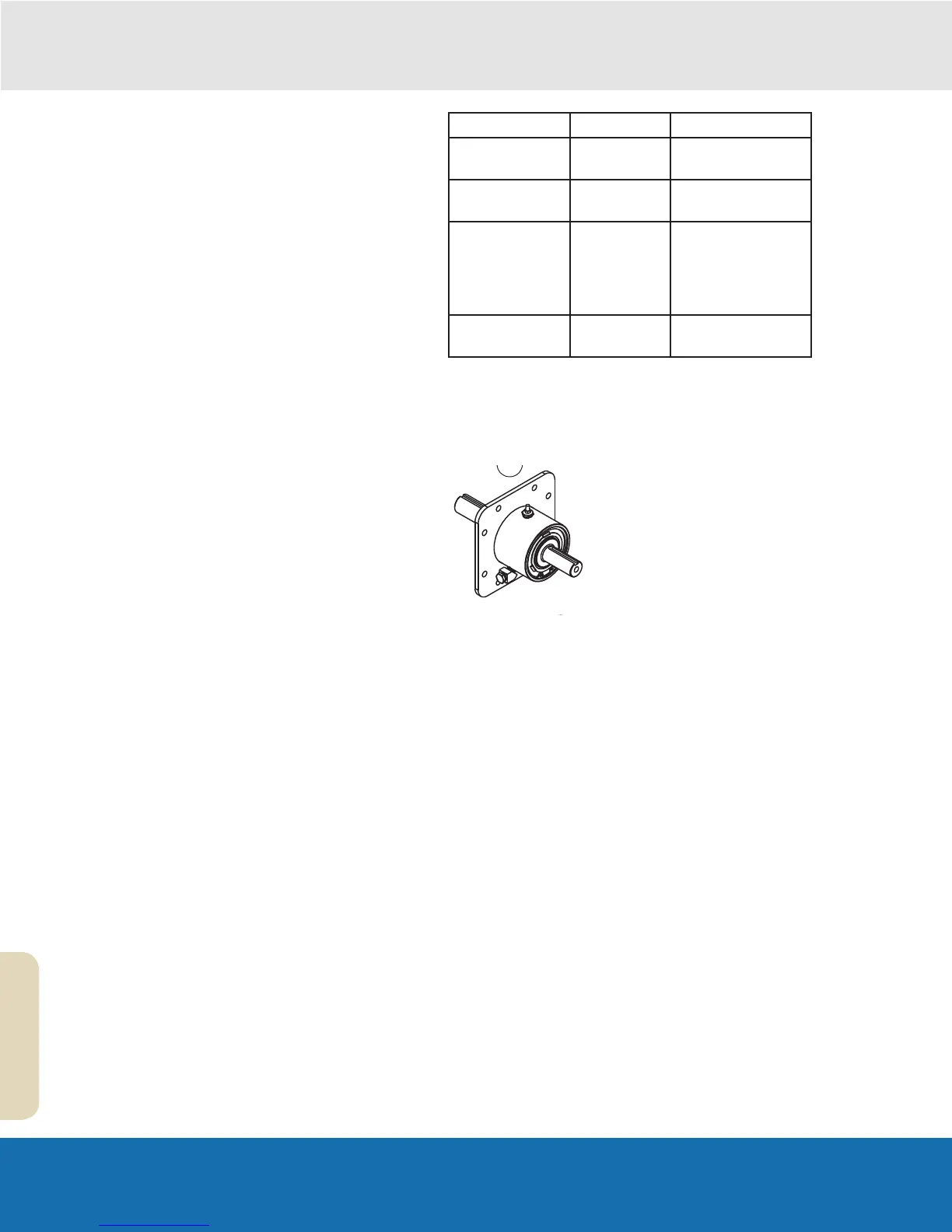

Fan Shaft Bearing Lubrication

The Hypervac utilizes lubed-for-life bearings and does

not require re-greasing. The adaptor housing is vented to

prevent over pressure.

The fan shaft uses a load adapter and this adapter is

serviced as a complete unit.

N

Y

:RORRIM

:NIARG

SSELNU SECNARELOT

DEIFICEPS ESIWREHTO

X6SG,NAF,GRB,YSSA

54B502

.CNI SEIRTSUDNI EZRAWHCS

B

NOITCARF

23 / 1

0. 1.

X

1

1t e ehS

1102 / 31 / 70

TRAHBILT

ELGNA

°1

LAMICED

00 . 30 .

000 . 510 .

FO

GN

ITTIK

94 . 78

:NOITPIRCSED LAIRETAM

:SKRAMER

:#LAIRETAM

:NOITPIRCSED

:EZIS

ETADYB NWARD

ON GNIWARD

ELACS TON OD

GNIWARD

:EZIS

:THGIEW

SNOITAREPO GNITUOR

Loading...

Loading...