Section 6 - Service

HV-18 revised 11/18 SCHWARZE HYPERVAC 81

6. When proper belt tension is achieved, re-thread the

loose adjustment nuts tightly against their power

module platform tabs. (If you’re adjusting the engine

away from the fan shaft, these would be the inner

adjustment nuts; toward the fan shaft, these would

be the outer adjustment nuts.) Tighten any loose jam

nuts back against their respective adjustment nuts.

7. Tighten the four tie-down bolts at the corners of the

engine skid.

8. Start the sweeper engine. Squealing or abnormal

vibrations indicate low belt drive tension. Adjust as

needed.

9. Re-bolt the belt guard back into position.

Replacing the Drive Belt

Replace the drive belt when it shows signs of wear, rather

than waiting for it to break. This practice will help to ensure

optimum sweeper performance and avoid downtime.

To replace the drive belt, reposition the sweeper engine.

1. Remove the sweeper engine’s keys and/or disconnect

the battery cable to prevent the sweeper engine from

being started accidentally.

2. Follow the procedures outlined in steps 1-4 in section

‘Drive Belt Tension Adjustment’ of this manual

3. Loosen the mounting bolts and jackscrews so the

engine skid is pushed toward the fan shaft.

4. As the engine skid moves toward the fan shaft, the

drive belt will become loose enough to be slipped

from its pulleys.

5. Inspect the pulley grooves for burrs and other

irregularities that may cause abnormal belt wear.

Replace when needed.

6. Slip the replacement belt into position.

7. Tighten the jackscrew nuts so the engine skid is

pulled away from the fan shaft.

8. Continue to tighten until the belt has 1/2” deflection

between the pulleys using 30 lbs. of pressure (roughly

the equivalent of pressing down on the belt with your

thumb).

9. Check the alignment of the pulleys, using a string or

straight edge, from the face of one pulley to the face

of the other. This will allow you to determine whether

the pulleys are in line with each other.

For slight misalignment, the pulleys

may be repositioned on their respective

shafts. If greater adjustment is needed

than pulley repositioning can achieve,

the entire engine/engine skid assembly

must be moved to obtain alignment.

The slotted tie-down holes of the

engine skid allow a limited amount of

forward & back movement.

10. Once proper pulley alignment is achieved, run the jam

nuts back against their respective jackscrew nuts.

11. Tighten the four tie-down bolts at the corners of the

engine skid.

12. Start the sweeper engine. Squealing or abnormal

vibrations indicate low belt drive tension. Adjust as

needed.

13. Re-bolt the belt guard back into position.

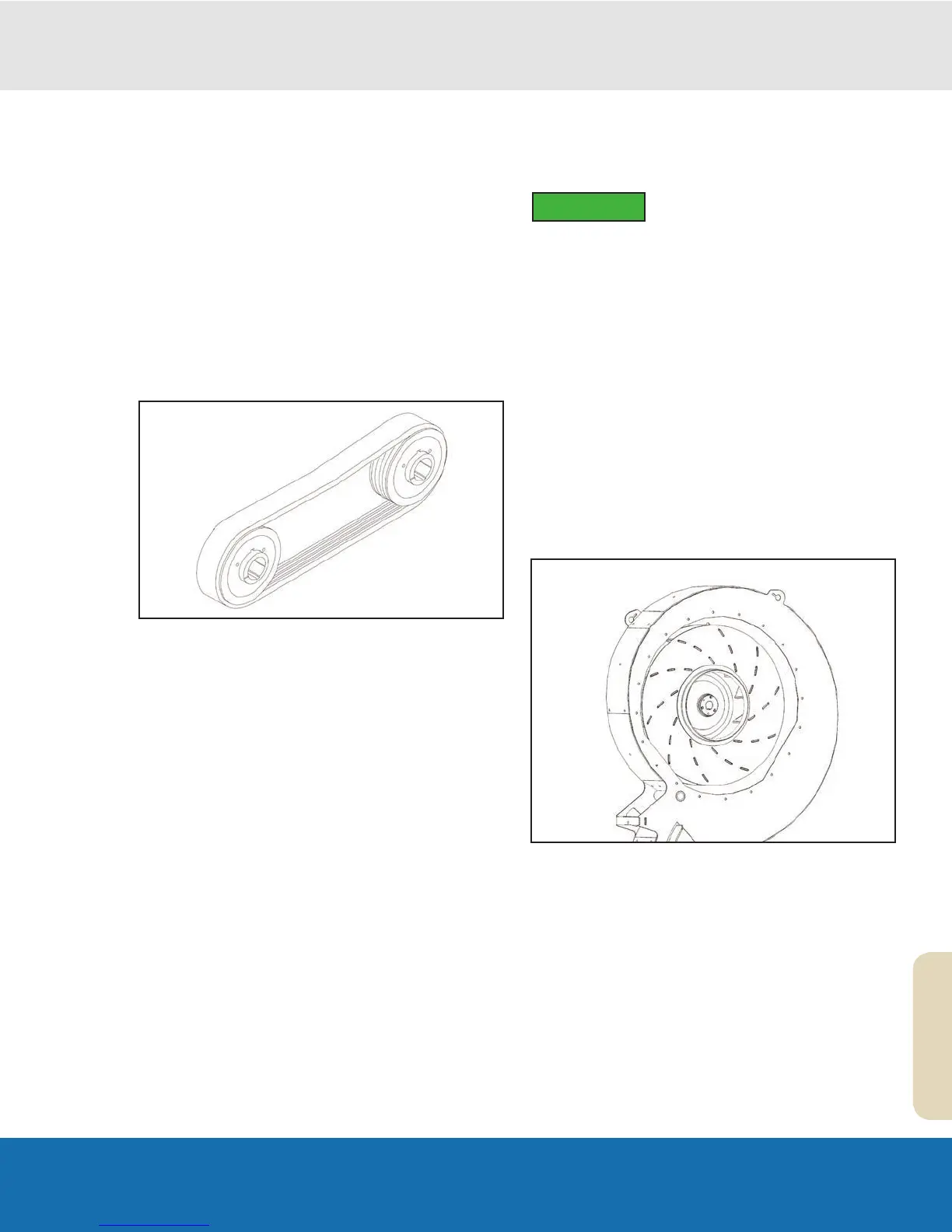

Inspecting the Sweeping Fan System

Over time, dust will cause wear to the fan house liner, fan

house liner bolts and fan blades.

Inspection

1. Raise the hopper and lower the safety prop into

position.

2. Remove the sweeper engine’s keys and disconnect

the battery cable to prevent the engine from starting

accidentally

3. Remove the back plate.

4. Using a flashlight, inspect the fan blades, fan bushing,

fan housing liner bolts and the fan housing liner for

wear.

IMPORTANT

Loading...

Loading...