Section 6 - Service

HV-18 revised 11/18 SCHWARZE HYPERVAC 79

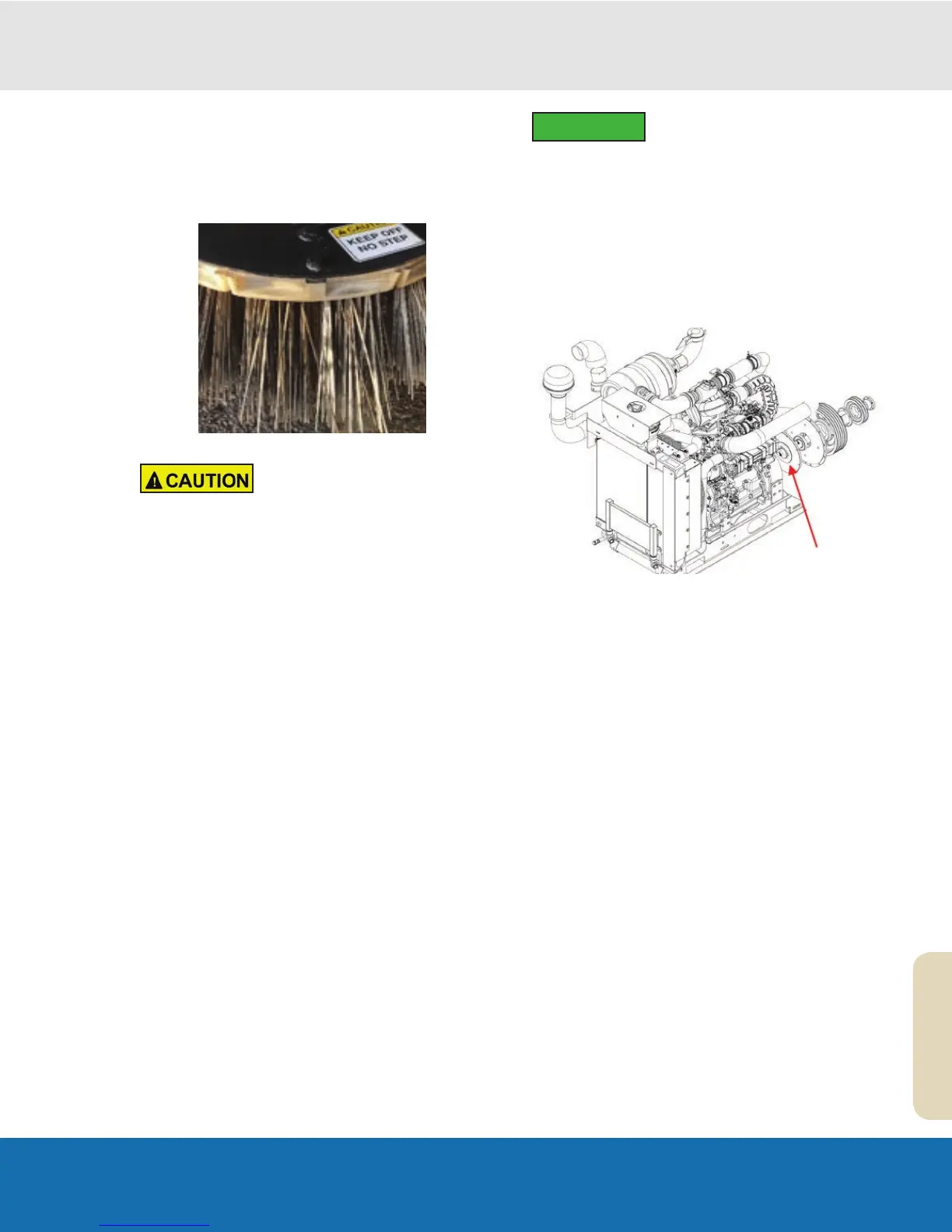

Replacing the Center Broom Bristles

Broom bristles should be replaced when they are worn to

approximately 6 inches in length. When broom bristles are

allowed to wear shorter, the bristles become too stiff and

loose their ability to ick debris.

Never work on or near the center

brooms when the brooms are rotating.

1. Remove the bolt that holds the broom segment in

place and remove worn segments moving around the

broom disc until all worn segments are detached.

2. To install a new broom segment, place the bristles in

place using the locating pin and reinstall hardware.

Important: Take special care to not over tighten the bolts.

6.6 Power Module

Because of the nature and operation of a sweeping

machine, it is recommended that servicing of the lters,

changing oil and other routine preventive maintenance

functions be performed somewhat more frequently than

recommended by the manufacturer of the engine.

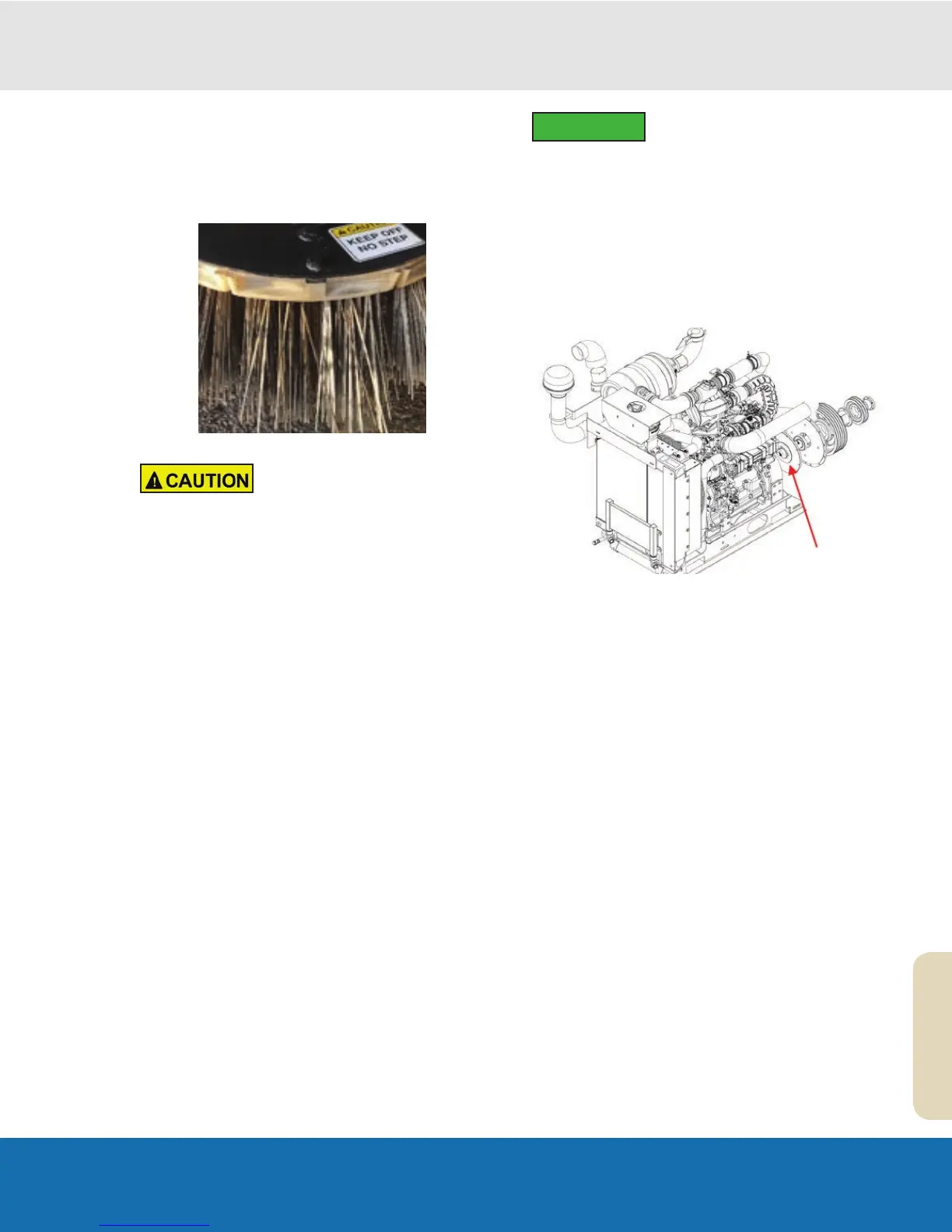

Auxiliary Engine Filters

The auxiliary engine has three lters: a fuel lter, an

oil lter and a dual element air lter. At a minimum,

all lters should be changed according to the engine

manufacturer’s warranty recommendations. We

recommend that the oil lter be changed more often if the

sweeper is operated under unusually dusty circumstances.

The air lter has a built-in air restriction indicator. When

the air lter becomes clogged and needs service, a

window on the air restriction indicator changes color.

Depending upon the type of air restriction indicator used,

this color change may be from clear to red, clear to yellow

or yellow to red. The air restriction indicator is normally

located on or near the auxiliary engine’s air lter canister

or optionally by remote in the truck cab on the console.

Do not clean air lter with high

pressure air. Clean or change the

air lter only when the air restriction

indictor’s ‘Need to Service’ window

has changed colors. Serious engine

damage can occur as a result of air

cleaner overservicing.

For air lter change and service information, please see

the Owner’s Manual for the auxiliary engine.

Replacing the Engine Stub Shaft

Stub shaft failures are rare but may, at some point, need

to be replaced. Causes for stub shaft failure include; too

much side-load created by a too tight drive belt, grooving

or warping of the stub shaft by a failed bearing and

stub shaft cracking or warping due to torque created by

the sudden stop of the fan’s drive train. In addition, we

suggest that the stub shaft be replaced whenever the

auxiliary engine is changed.

Replacement

1. Remove the sweeper engine’s keys and/or disconnect

the battery cable to prevent the sweeper engine from

being started accidentally.

2. Loosen the belt tension as outlined in the ‘Drive Belt

Tension Adjustment’ section.

3. Turn the jackscrew nuts so the engine skid is pushed

toward the fan shaft.

4. As the engine skid moves toward the fan shaft, the

drive belt will become loose enough to be slipped

from its pulleys.

5. Remove the three 3/8” bolts and lockwashers from

the stub shaft pulley bushing.

6. Insert two of the 3/8” bolts into the two tapped holes

of the stub shaft pulley bushing.

7. Tighten the bolts evenly, alternating from one to the

other. This will push the pulley off the stub shaft pulley

bushing.

IMPORTANT

Loading...

Loading...