Section 6 - Service

74 SCHWARZE HYPERVAC HV-18 revised 11/18

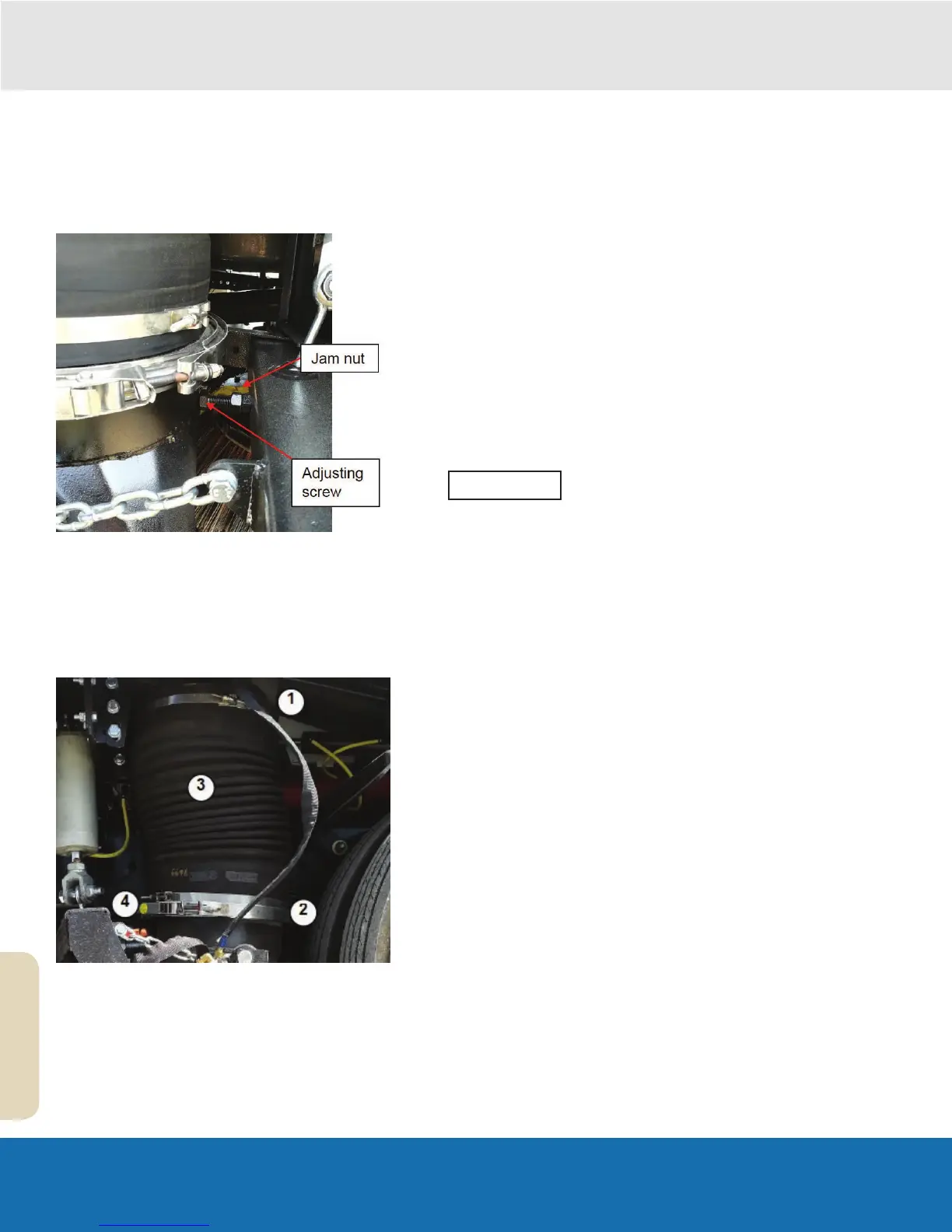

Nozzle Tilt Adjustment

To maintain a proper gap around the nozzle as shown in

the Adjusting the Nozzle aps section, the angle of the

nozzle may need to be adjusted. Adjust the nozzle angle

as shown below until the desired gap between the nozzle

is consistent.

1.

Loosen the jam nut on the screw.

2. Tighten or loosen the adjusting screw until the desired

level of pitch is achieved.

3. Tighten the jam nut to prevent the screw from

loosening.

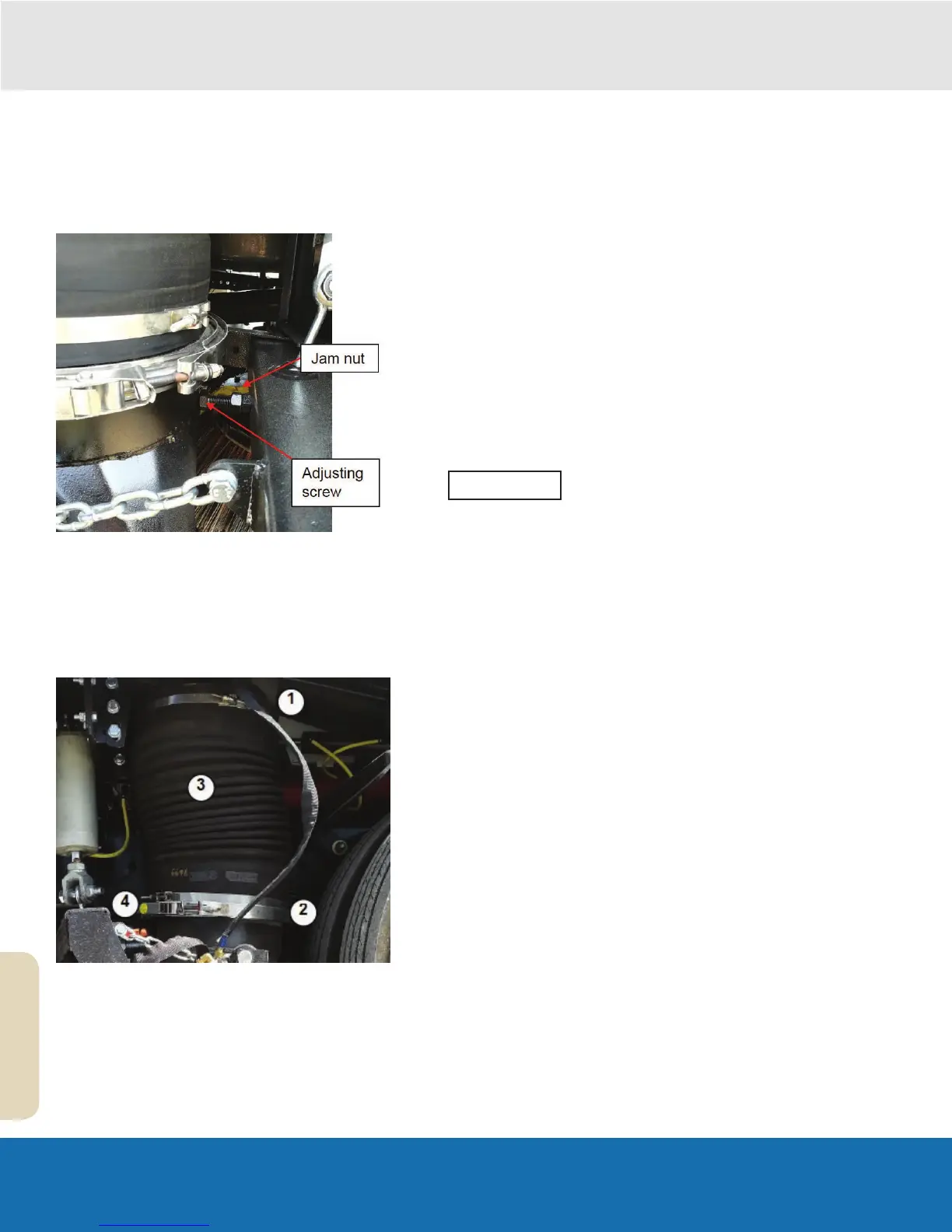

Replacing the Nozzle Hose

1.

Release the Clamp locking the HD Suction Hose to

the Upper Tube of the Nozzle.

2. Loosen the two remaining Hose Clamps. One will be

located on the top section of the HD Suction Hose,

the second will be located on the bottom section of

the HD Suction Hose.

3. Rotate or replace the HD Suction Hose.

4. Use the Clamp to lock the bottom section of the

HD Suction Hose to the Upper Tube of the Nozzle.

Tighten the two Hose Clamps into place.

6.3 Hopper

The hopper is a simple component and needs little in the

way of maintenance. Clean the hopper daily to prevent

debris build-up and follow the lubrication schedules.

Replacing the Hopper Seals

It is important that the sweeper’s seals on the fan housing

be kept in the best condition possible. These include

the seals on the suction hose inlet, around the hopper’s

inspection door opening and on the rear door. Pickup

power is vacuum dependent, so a tight seal can make a

signicant difference in pickup ability. Maintain resilience

by keeping the seals well lubricated with a good grade of

petroleum-based jelly or grease.

Lubrication of the side inspection door

seals is not necessary.

For longer seal life, when the sweeper is parked for an

extended period of time, leave the dump and all inspection

doors open and raise the hopper a few inches so their

seals can regain their shape.

Eventually the seals will become worn or non-resilient and

must be replaced.

Replacement

1. Use a gasket scraper, putty knife or screwdriver to

remove the seal from its sweeper component. Get the

metal surface as clean as possible. Be sure it is free

of all dirt, old glue, and seal material.

2. Liberally apply a coat of weather-strip-type adhesive

onto the new seal and body component. Allow the

adhesive to set up for several minutes (follow the

adhesive manufacturer’s instructions) and then put

the new seal in place.

Replacing the Hopper

Needed for a hopper replacement:

• Two workers

• Overhead crane

• Support blocks

Removal

1. Install approved lifting eyes and load spreader if

needed in the two front lifting eye positions.

2. Raise the hopper and insert the safety props.

NOTE

Loading...

Loading...