Section 6 - Service

88 SCHWARZE HYPERVAC HV-18 revised 11/18

Cleaning the Water Manifold Solenoid

The water manifold solenoid should be cleaned when the

nozzle has been cleaned or replaced and:

• Water leaks or sprays weakly from the nozzles.

• Little or no water flows from the nozzles.

Never use ANY type of cleaning uid

to clean the solenoid valve plunger

assembly or seals.

1. Shutoff all electrical current and pressure.

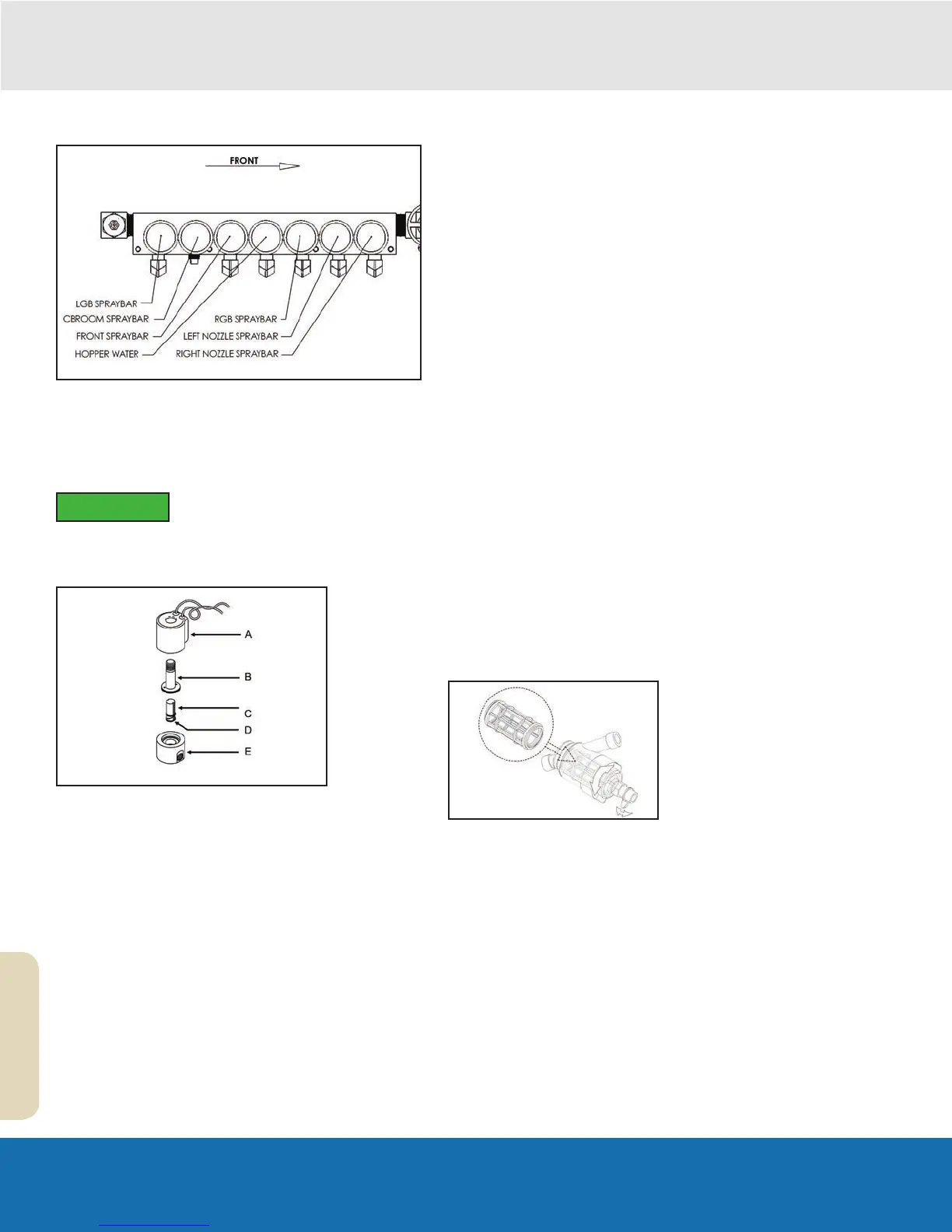

A Solenoid Housing

B Sleeve Assembly

C Plunger

D Soft Insert

E Base

2. Remove the nut at the top of the solenoid valve.

3. Remove the name plate, coil and housing from the

body.

4. If the valve does not leak from the seat and the

plunger does not stick in the energized position,

the problem is electrical and further cleaning is not

required.

5. If the valve leaks from the seat or the plunger does

stick in the energized position, proceed to the next

step.

6. Use the supplied Peter Paul wrench to remove the

sleeve assembly.

7. Examine the soft inserts in the plunger and carefully

clean.

8. Examine the inside of the sleeve assembly and

carefully clean.

9. If the inserts show excessive wear, replace the

plunger.

10. If the valve emitted a loud buzzing noise during

operation, examine both the inside of the sleeve and

upper portion of the plunger and remove all foreign

matter.

11. After cleaning or replacing parts, verify that both the

ange seal and the return spring are in place.

12. Loosely screw the sleeve assembly into the body.

13. If the valve has a sleeve port, cap the port and apply

pressure to the port leading to the body chamber.

14. If the media is air or gas, apply water to the joint and

watch for air bubbles.

15. Reattach the name plate, coil, and housing to the

body.

16. Carefully tighten the nut at the top of the solenoid

valve. Excessive tightening of the nut can cause

unnecessary strain on either the sleeve assembly or

the coil under the housing.

17. Restart the electrical current and pressure.

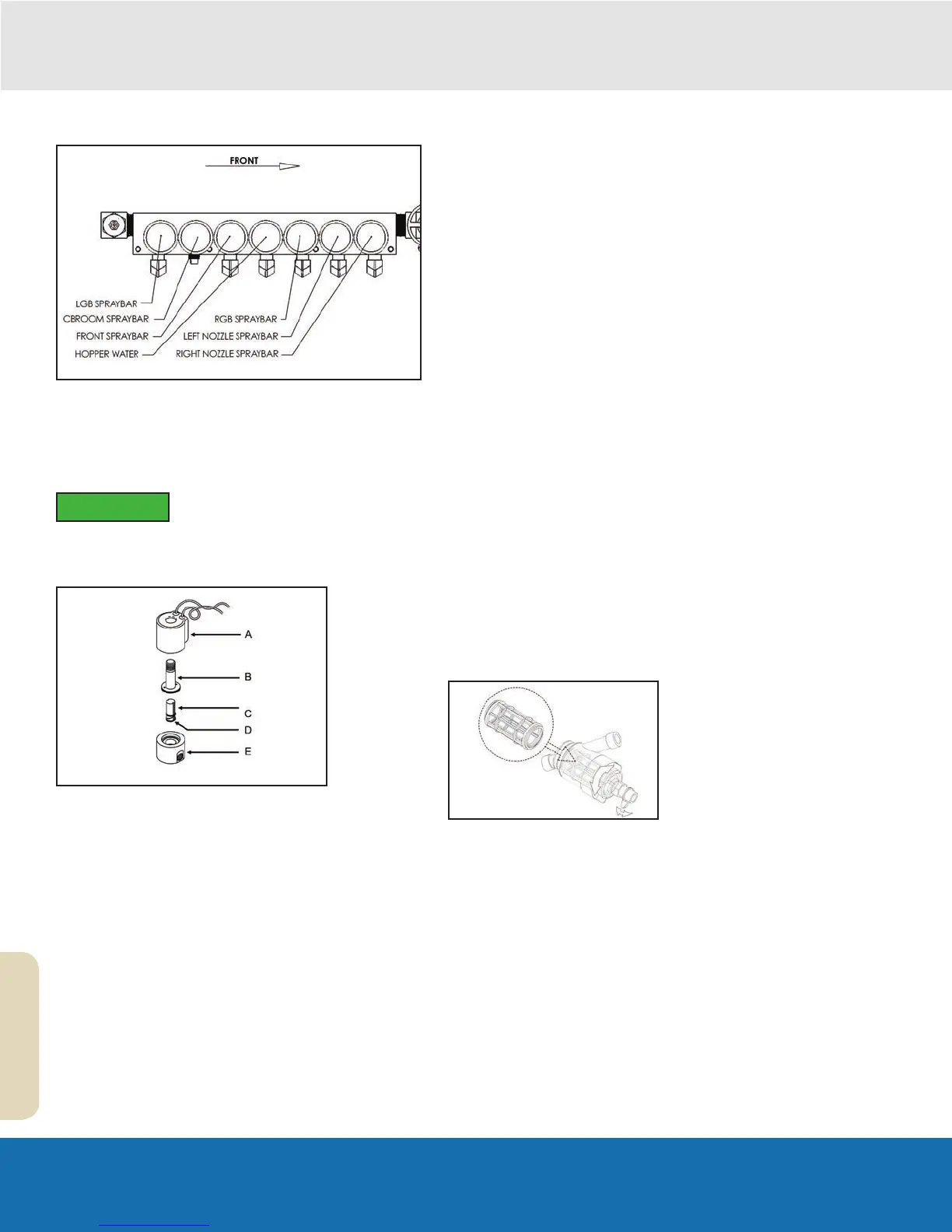

Cleaning/Replacing the ‘Y’ Strainer

Cleaning the ‘Y’ strainer requires opening the ‘Y’ strainer

housing. This procedure should be done at the end of the

work shift when the reservoir’s water level will be at its

lowest.

1. Turn off the ball valve.

2. Unscrew the bottom of the ‘Y’ strainer.

3. Remove the screen from inside the ‘Y’ strainer

housing and examine.

4. Remove any debris inside the ‘Y’ strainer and rinse

the cylindrical screen.

5. If the strainer is damaged, replace it.

6. Slip the screen back into position.

7. Reassemble the ‘Y’ strainer housing.

IMPORTANT

Loading...

Loading...