Section 6 - Service

84 SCHWARZE HYPERVAC HV-18 revised 11/18

Replacing the Fan Guard

1.

Remove the hardware retaining the Fan guard located

on the top and side of the guard to obtain excess the

Hydraulic pump and Fan Drive belts.

Caution: Do not remove while Aux engine is running,

Replacing the Fan Shaft Bearing

Under normal operating conditions, the bearings should

last approximately 2500 hours (check the auxiliary

engine’s hour meter). Bearing failure is accompanied by

abnormal noise, vibration and/or the slinging of grease

caused by ruptured bearing seals. Worn bearings should

be replaced immediately to prevent damage to other

sweeper components. Usually, accompanying drive belts,

pulleys and bushings are also replaced. This ensures

proper performance and eliminates repetitive maintenance

and downtime.

Disassembly

1. Follow the procedures outlined in steps 1-7 in section

‘Replacing the Fan System Fan’ of this manual

2. Follow the procedures outlined in steps 1-4 in section

‘Drive Belt Tension Adjustment’ of this manual

3. Remove fan pulley off load adapter assembly shaft.

4. Remove the 8 bolts holding load adapter to fan

housing support upright and remove load adapter.

The adapter is services as a complete

unit.

5. Inspect the fan shaft drive pulley and drive belt. If

either is damaged or too worn for reuse, discard and

replace.

Replacement

1. Install the 8 bolts holding load adapter to fan housing

support upright.

2. Replace fan pully onto new load adapter shaft.

3. Check the alignment of the pulleys, using a string or

straight edge, from the face of one pulley to the face

of the other to determine whether the pulleys are in

line with each other.

4. If the pulleys are misaligned, back the fan shaft

drive pulley off its bushing, move both in the proper

direction for alignment, then retighten the bushing/

pulley bolts.

5. Inspect the drive belt for wear and replace it with a

new one if needed.

6. Slide the drive belt onto the engine and fan shaft

pulleys.

7. Adjust the drive belt tension.

8. Inspect the fan for wear and replace it with a new one

if needed.

9. Follow the steps outlined under ‘Replacement’ in

section, ‘Fan Replacement’ section of this manual.

10. Swing the hopper safety prop back into its travel

position.

11. Reconnect the engine’s battery cable, lower the

hopper and check the operation of the sweeper.

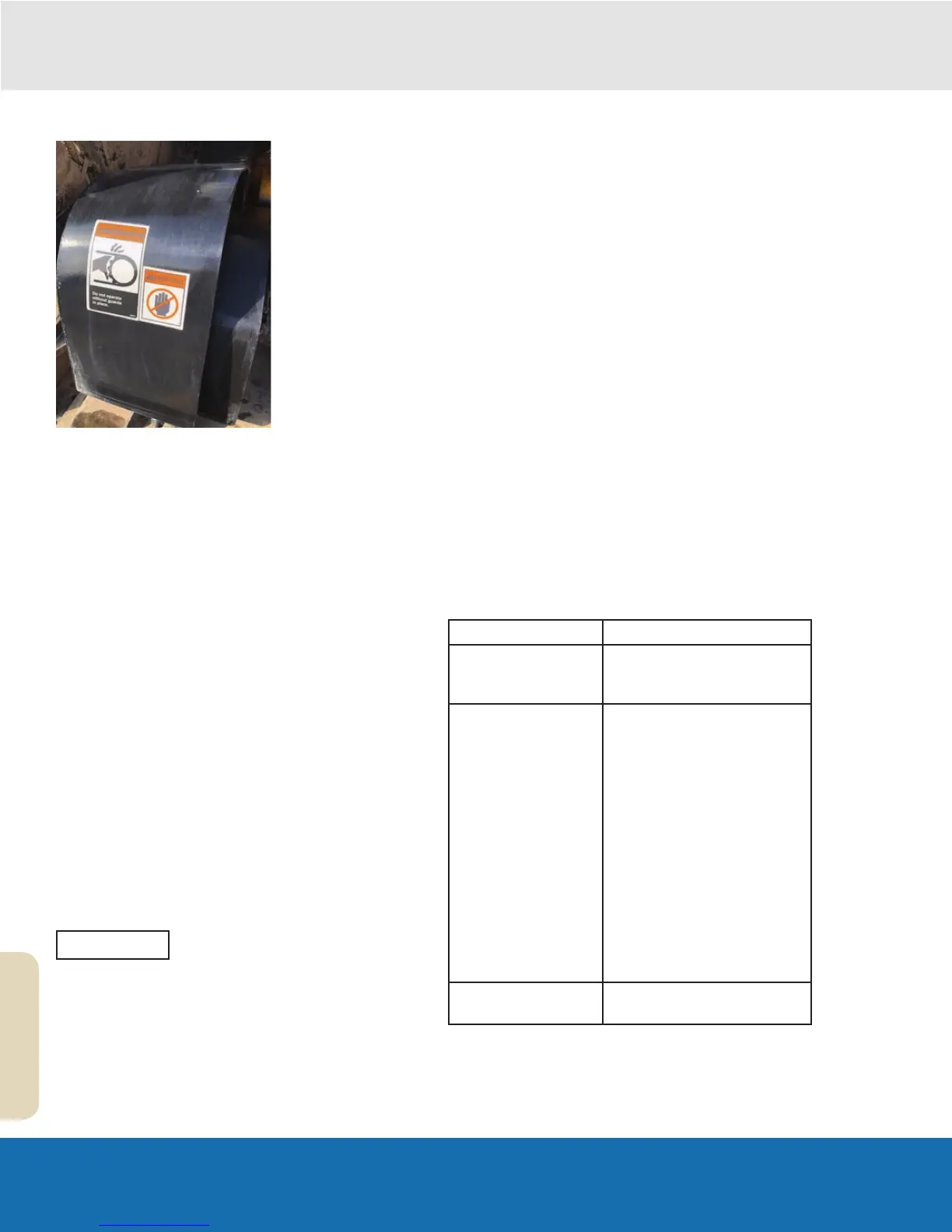

Hydraulic System Service Schedule

We recommend the service listed in the following table.

Service Frequency

Check hydraulic

system pressure and

adjust.

As Needed

Change the hydraulic

uid and lters.

• Service records show

that the new sweeper has

completed its first 500

hours of operation

• Thereafter, service

records should show that

the sweeper has been

operated 2,000 hours

since its last hydraulic fluid

change.

• If the hydraulic fluid

becomes cloudy, water

has contaminated the

system. It should be

changed and flushed.

Check hydraulic uid

level.

Daily

NOTE

Loading...

Loading...