Section 6 - Service

80 SCHWARZE HYPERVAC HV-18 revised 11/18

8. Remove the pulley and its bushing from the stub

shaft.

9. Remove the bearing plate from the end of the

auxiliary engine bell housing. Inspect the plate for

irregularities. If none are found, the bearing plate may

be used again.

10. Remove the old stub shaft from the end of the

auxiliary engine.

11. Clean the flywheel and replacement stub shaft using

lacquer thinner.

12. Fasten the replacement stub shaft to the auxiliary

engine using 60 ft. lbs. of torque on each bolt.

13. Use a dial indicator and ensure that the stub shaft is

in-line with the crankshaft. The stub shaft must be no

more than .008” off-center.

If the stub is more than .008” off-center,

it should be replaced.

14. Place the replacement bearing onto the end of the

shaft. Using a piece of pipe placed over the stub

shaft’s end, drive the bearing down the stub shaft until

it rests against its seat.

15. Slip the bearing plate down the stub shaft and onto

the bearing.

16. Bolt the bearing plate too the auxiliary engine.

17. Slide the stub shaft pulley and its taper-lock bushing

onto the end of the stub shaft.

18. Insert the bolts through the taper-lock bushing onto

the end of the stub shaft.

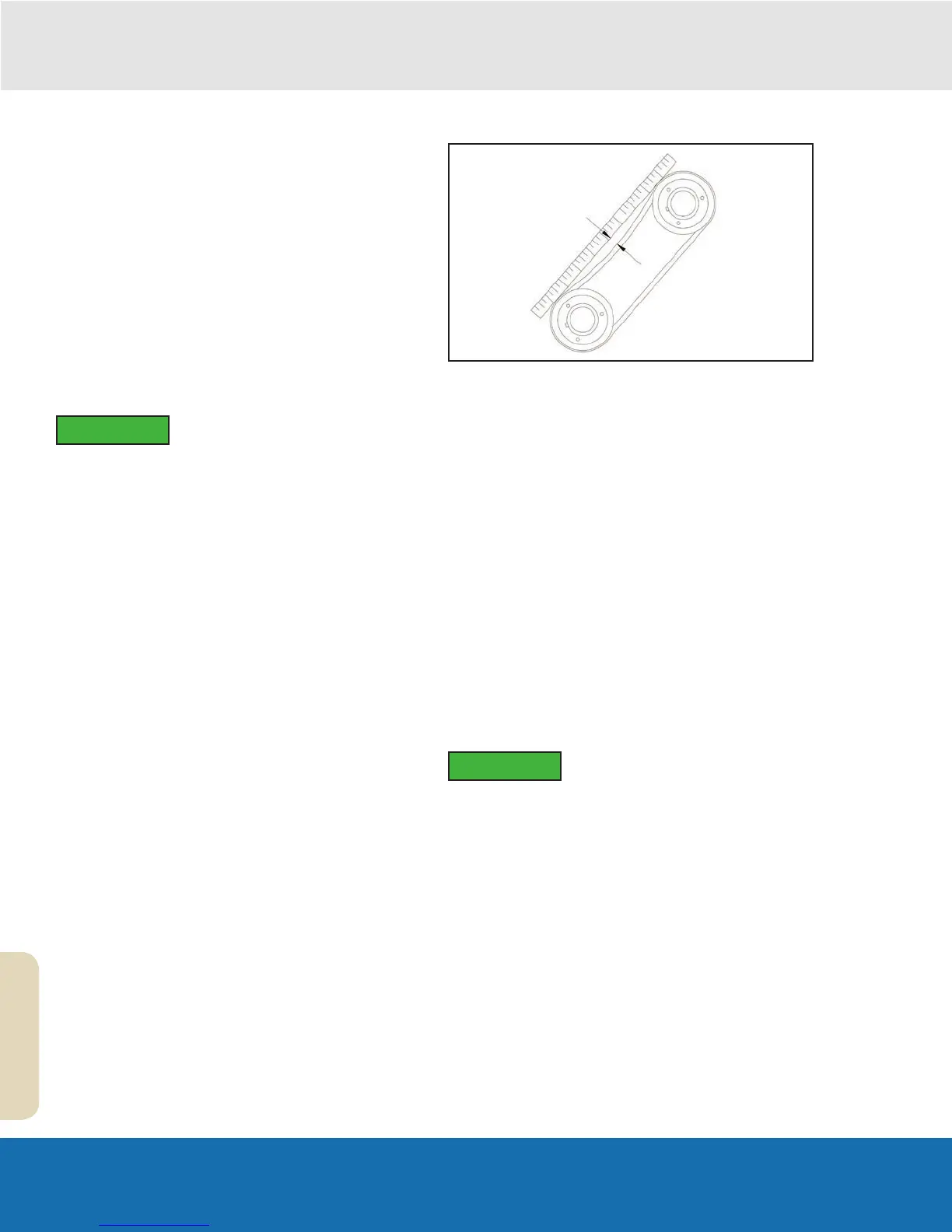

19. Check the alignment of the pulleys, using a string or

straight edge, from the face of one pulley to the face

of the other to determine whether the pulleys are in

line with each other.

20. If the pulleys are misaligned, back the stub shaft

pulley off its bushing, move both in the proper

direction for alignment, them retighten the bushing/

pulley bolts.

21. Inspect the drive belt for wear and replace it with a

new one if needed.

22. Slide the drive belt onto the stub shaft and fan shaft

pulleys.

23. Tighten the belt tension as outlined in the ‘Drive Belt

Tension Adjustment’ section.

24. Replace the belt guard.

Adjusting the Drive Belt Tension

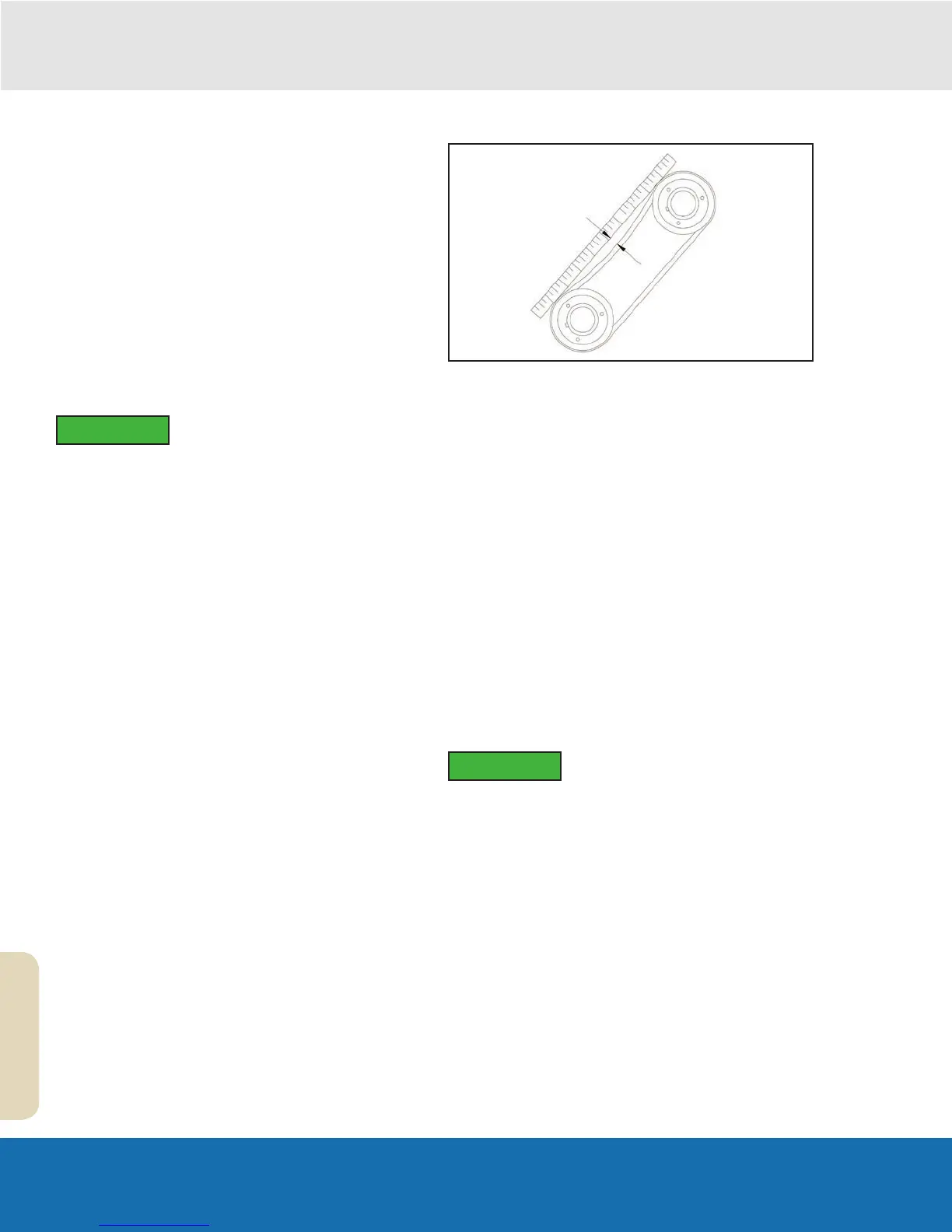

The drive belt is a belt that drives the fan shaft. Check the

belt tension periodically. This is accomplished by pressing

down on the belt halfway between the two pulleys. With

35- 40 lbs. of pressure (the approximate equivalent of

very rm pressure from on it from your thumb), the belt

should deect about 1/2” - 3/8”. An average belt, over the

course of its life, will stretch slightly and the belt will need

adjustment. This will be especially true during the rst 75-

100 hours of operation.

The auxiliary engine, along with its engine skid, can

be moved in the direction of the fan shaft (to loosen or

remove the belt) or away from the fan shaft (to tighten the

belt).

1. Loosen the bolts that connect the two piece belt

guard.

2. Loosen (but do not remove) the bolt which holds each

of the four outer corners of the engine skid to the top

of the power module platform.

3. Locate the threaded rods known as jackscrews.

Before adjusting the jackscrews, mark

the present position of the engine

skid, both at the front and rear, on the

power module platform. This will allow

you to determine how far the engine

skid has been moved and whether the

center line of the auxiliary engine is still

parallel with the fan shaft.

4. Loosen the jackscrews’ jam nuts.

5. By running the adjustment nuts in or out, the engine

skid may be moved toward or away from the shaft.

Alternate adjusting the jackscrew nuts front to rear

so that movement of the engine skid is even and the

engine skid does not become misaligned. If you turn

the front jackscrew three revolutions, then turn the

rear jackscrew three revolutions.

IMPORTANT

IMPORTANT

Loading...

Loading...