Page 72

STAT

IM

2000/2000S Service Guide

96-106775 Rev 5.0

3. Troubleshooting Cycle Faults

STATIM 5000/5000S/5000 G4 Service Guide

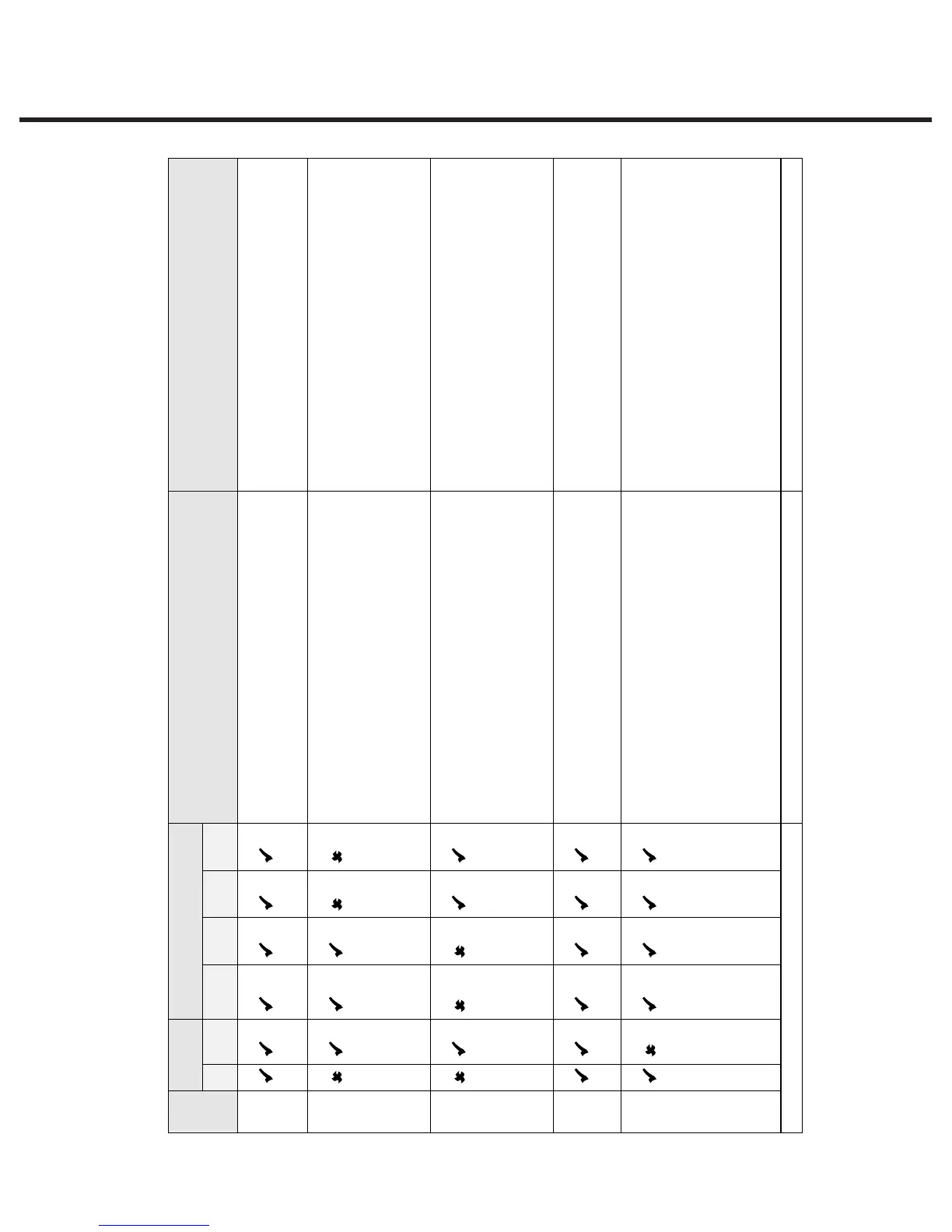

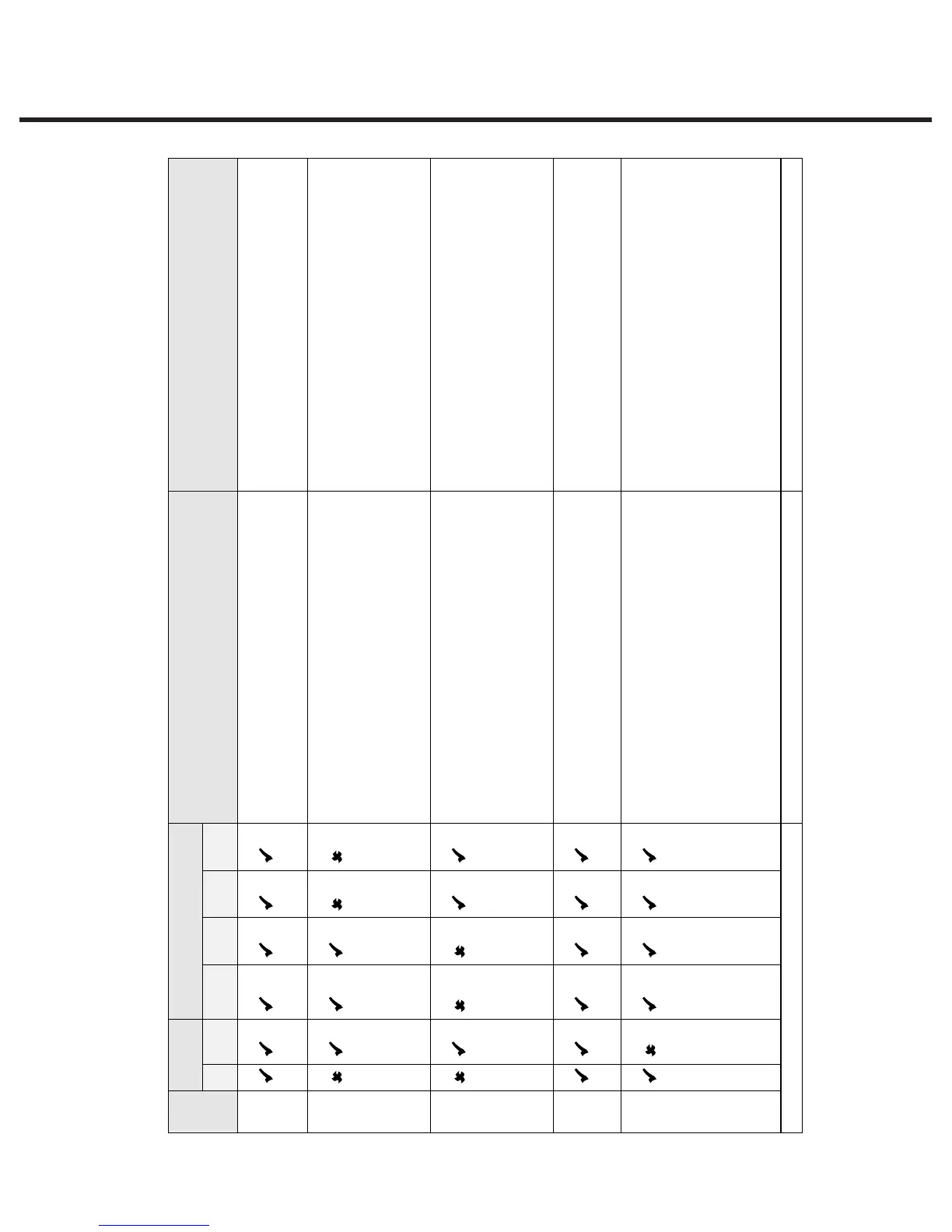

No.

Description of Fault

Probable Cause (or causes) of Fault

S Non

1.xx/

4.xx 5.xx 6.xx

The software has failed to detect a need to

pump water within 90 seconds of the start of the

cycle.

• Blown thermal fuse (check the following)

o Pump delivery

o Steam generator triac

• Steam generator fault (open circuit).

26

(i)

The sterilization phase has failed to start within 3

minutes of the cassette reaching the sterilization

temperature. Note: for rev 4.xx software only,

the unit has to fail on 3 consecutive cycles

for CF26 to display.

• Calibration imbalance (boiler

thermocouple to chamber

thermocouple)

• Poor pump delivery

• Sticking solenoid valve

• Check Vref is 2.520V± 0.001V

26

(ii)

The sterilization phase has failed to start within 3

minutes of the cassette reaching the sterilization

temperature. Note: the unit has to fail on 3

consecutive cycles for CF26 to display.

“Cycle Interrupted” displayed for the first 2

occurrences.

• Calibration imbalance (validation

thermocouple to chamber

thermocouple)

• Poor pump delivery

• Sticking solenoid valve

• Check Vref is 2.520V± 0.001V

27

The temperature of the steam generator failed to

drop bellow a set-point temperature (150°C or

165°C) in a timeout period or during a panic

pump situation.

• Poor pump delivery

• Failed water sensor (level)

• Contaminated steam generator

28

The cassette pressure rose above a ceiling

value.

• Pressure measurement failure.

• Calibration imbalance (pressure

transducer to chamber thermocouple)

• Sticking solenoid valve (closed)

• Failed solenoid coil

• Blocked cassette exhaust duct

• Obstructed exhaust tubing (kink)

• Blockage or restriction in pressure

Loading...

Loading...