Page 73

STAT

IM

2000/2000S Service Guide

96-106775 Rev 5.0

3. Troubleshooting Cycle Faults

STATIM 5000/5000S/5000 G4 Service Guide

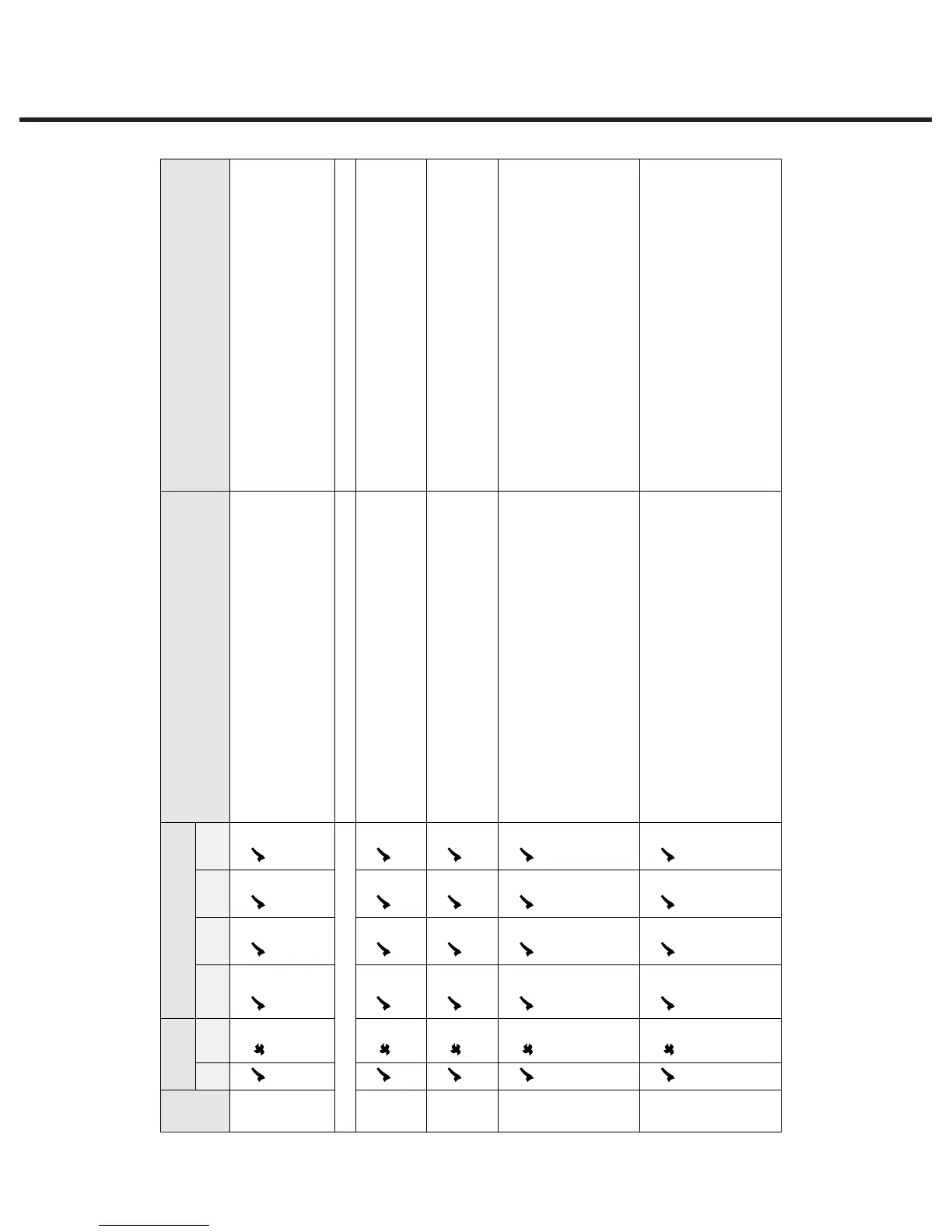

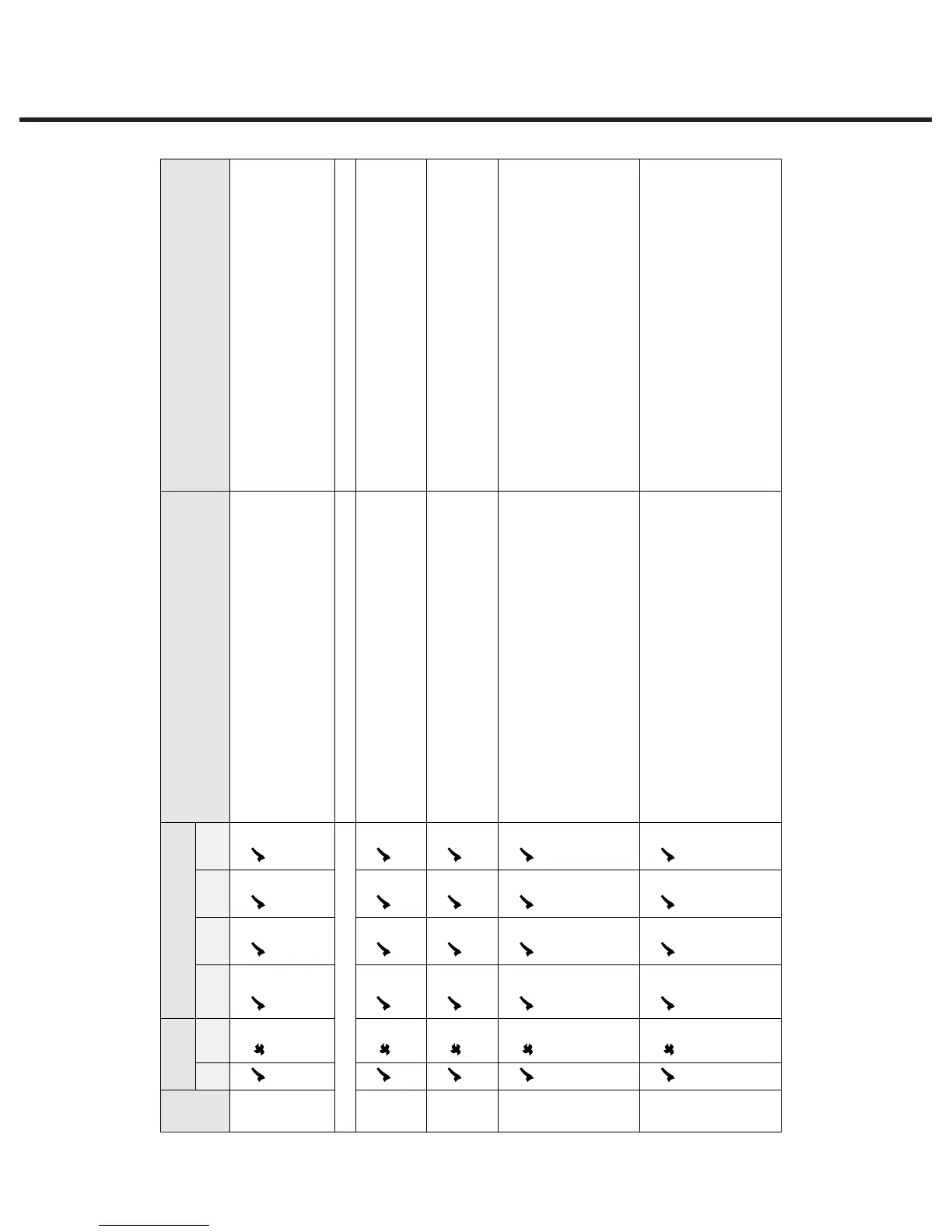

No.

Description of Fault

Probable Cause (or causes) of Fault

S Non

1.xx/

4.xx 5.xx 6.xx

The cassette temperature failed to reach the

sterilization temperature within 15 seconds of

the theoretical cassette temperature calculated

from the measured cassette pressure reaching

the sterilization temperature.

• Poor air removal during conditioning

(exhaust blockage).

• Calibration imbalance (pressure

transducer or chamber thermocouple)

• Blockage or restriction in pressure

Not used

50

For the Rubber and Plastics cycle, the chamber

temperature dropped below the sterilization

temperature, allowing for measurement error

(i.e. Tchm < 121°C).

• Poor air removal during conditioning

(exhaust blockage).

• Not able to generate steam

•

51

For the Rubber and Plastics cycle, the chamber

temperature rose more than 4 C° above the

sterilization temperature, allowing for

measurement error (i.e. Tchm > 125°C).

• Sticking solenoid valve (closed)

• Failed solenoid coil

• Blocked cassette exhaust duct

•

Obstructed exhaust tubing (kink)

52

For the Rubber and Plastics cycle, the

theoretical chamber temperature as calculated

from the measured chamber pressure was more

than 2°C below the measured chamber

temperature, allowing for measurement error.

• Calibration imbalance (pressure

transducer or chamber thermocouple)

• Sticking solenoid valve (closed)

• Failed solenoid coil

• Blocked cassette exhaust duct

• Obstructed exhaust tubing (kink)

• Poor air removal

53

For the Rubber and Plastics cycle, the

theoretical chamber temperature as calculated

from the measured chamber pressure was more

than 2°C above the measured chamber

temperature, allowing for measurement error.

• Calibration imbalance (pressure

transducer or chamber thermocouple)

• Sticking solenoid valve (closed)

• Failed solenoid coil

• Blocked cassette exhaust duct

• Obstructed exhaust tubing (kink)

• Poor air removal

Loading...

Loading...