Section 04 ENGINE (2-STROKE)

Subsection 06 (BOTTOM END)

04-06-16 SMR2003-011_04_06A.FM

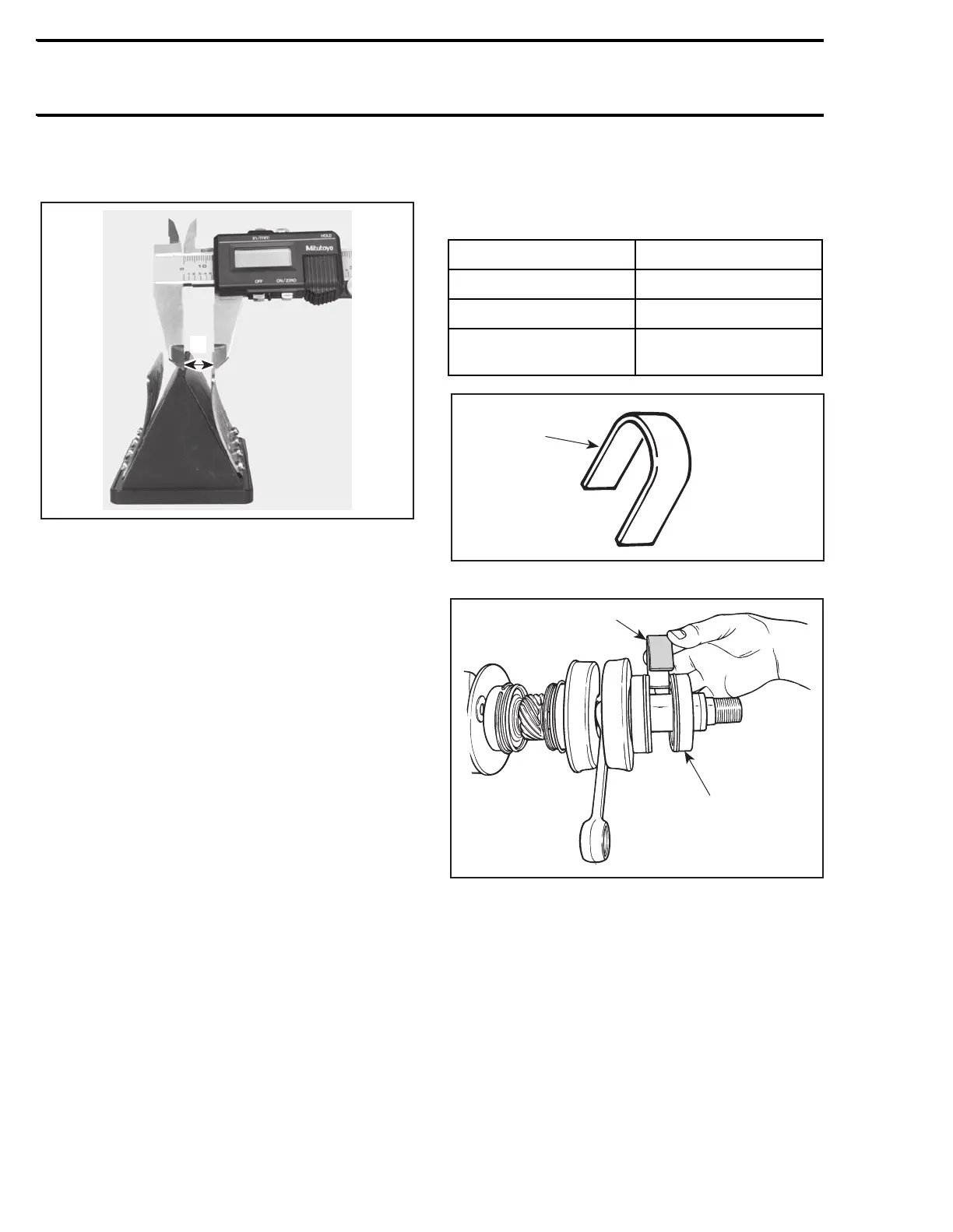

Check stopper distance from center of reed valve

block.

A. 13 ± 0.25 mm (.512 ± .010 in)

NOTE: Distance should be the same on both sides.

Bent stopper as required to obtain the proper dis-

tance.

Air Compressor

Refer to ENGINE MANAGEMENT for compo-

nents inspection. However, if you find aluminum

dust or debris in this area, they may have flowed

toward the injection oil reservoir. In this case, the

oil reservoir and lines must be flushed and the fil-

ter replaced.

CAUTION: Failure to properly clean the oil sys-

tem will result in serious engine damage.

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedures. However pay particular attention

to the following.

NOTE: It is recommended to spray BOMBARDIER-

ROTAX injection oil on all moving parts when re-

assembling the engine.

Crankshaft and Bearing

Apply Loctite 767 anti-seize on part of crankshaft

where bearing fits.

Prior to installation, place bearings no. 4 into a

container filled with oil, previously heated to 75°C

(167°F). This will expand bearing and ease instal-

lation.

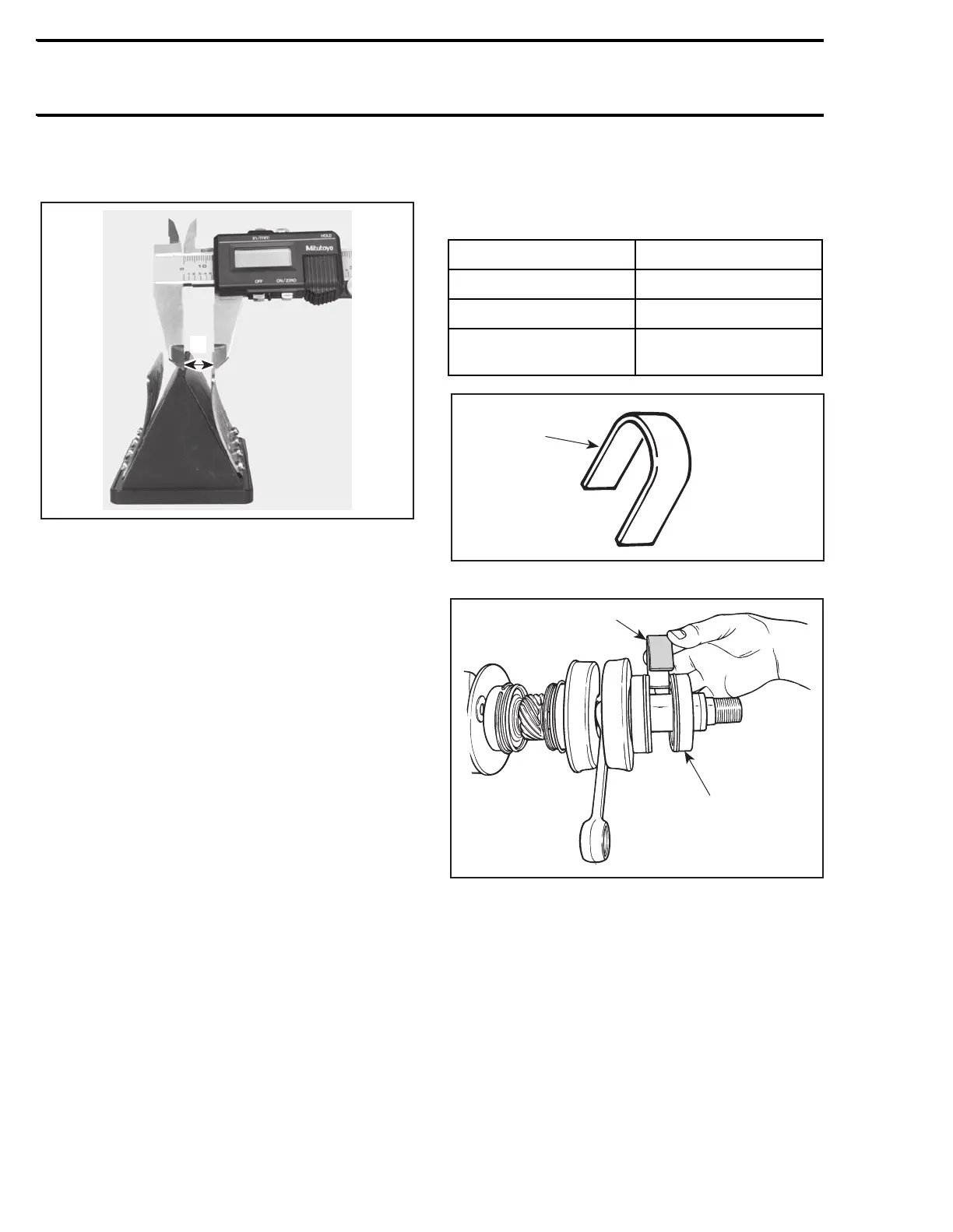

To properly position the outer bearing(s), a dis-

tance gauge must be temporarily installed against

the inner bearing. Slide the outer bearing until

stopped by the distance gauge, then remove it.

1. Distance gauge

TYPICAL

1. Distance gauge

2. Outer bearing

Distance Ring

When installing the distance ring no. 12, make

sure to position it with its chamfer toward the

counterweight of the crankshaft.

ENGINE DISTANCE GAUGE

717 P/N 529 034 800 (PTO)

787 RFI P/N 529 034 900 (MAG)

947DI

P/N 529 035 100 (MAG)

P/N 529 035 000 (PTO)

F01B0HA

1

F01D1YA

1

2

Loading...

Loading...