Section 12 ELECTRICAL SYSTEM

Subsection 02 (IGNITION SYSTEM (CARBURETED ENGINES))

12-02-12 SMR2003-035_12_02A.FM

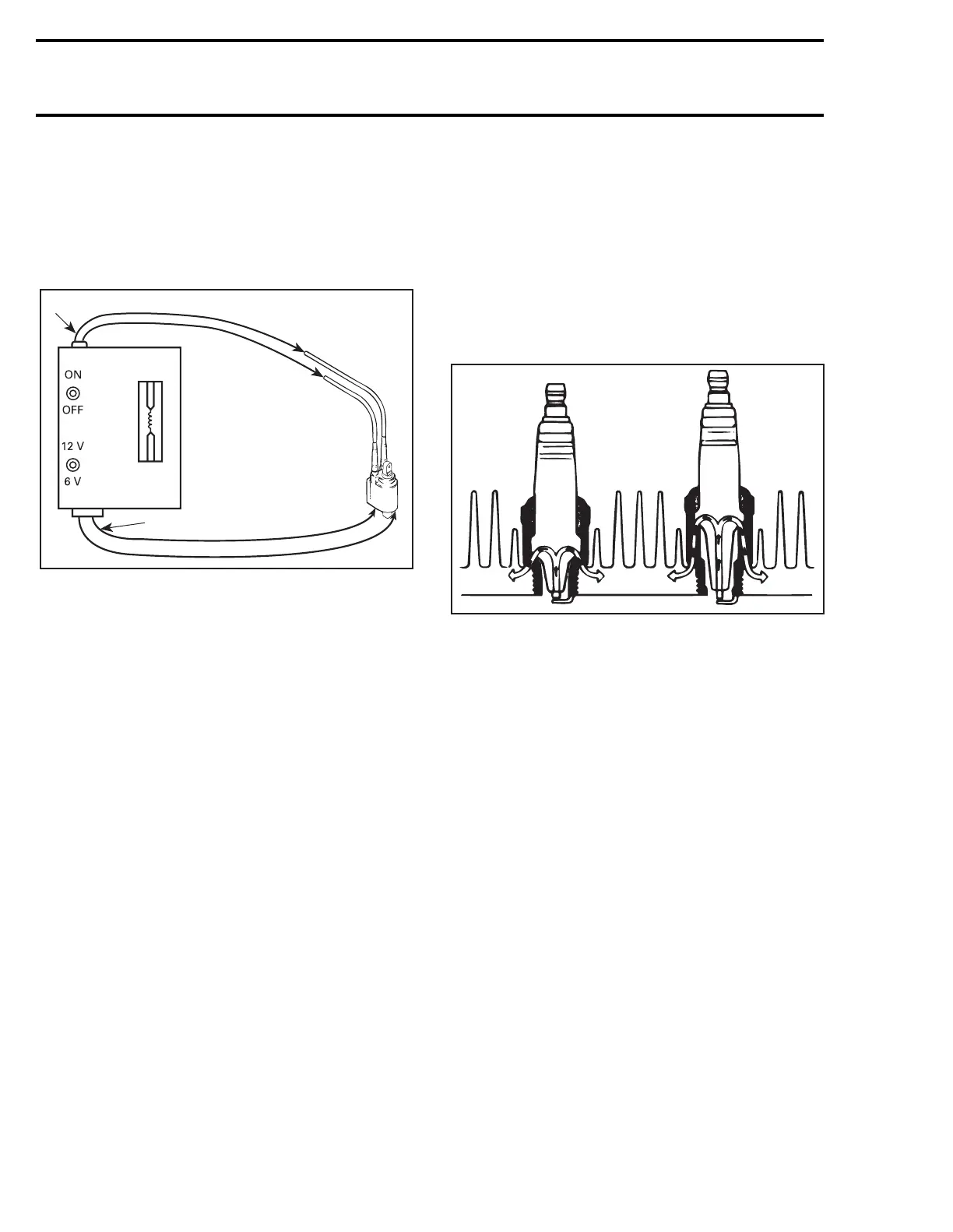

1. With ignition coil removed from craft, discon-

nect spark plug caps from high tension cables.

2. Hook high tension leads from tester to ignition

coil high tension cables.

3. Connect 2 smaller tester leads to primary of ig-

nition coil.

TYPICAL

1. Leads to secondary

2. Leads to primary

4. Turn power switch to 12 volts and you should

observe spark jumping at a predetermined gap

of 7 to 8 mm (.276 to .311 in).

If there is no spark, if it is weak or intermittent, the

coil is defective and should be replaced.

SPARK PLUGS

Disassembly

First unscrew the spark plug one turn.

Clean the spark plug and cylinder head with pres-

surize air then completely unscrew.

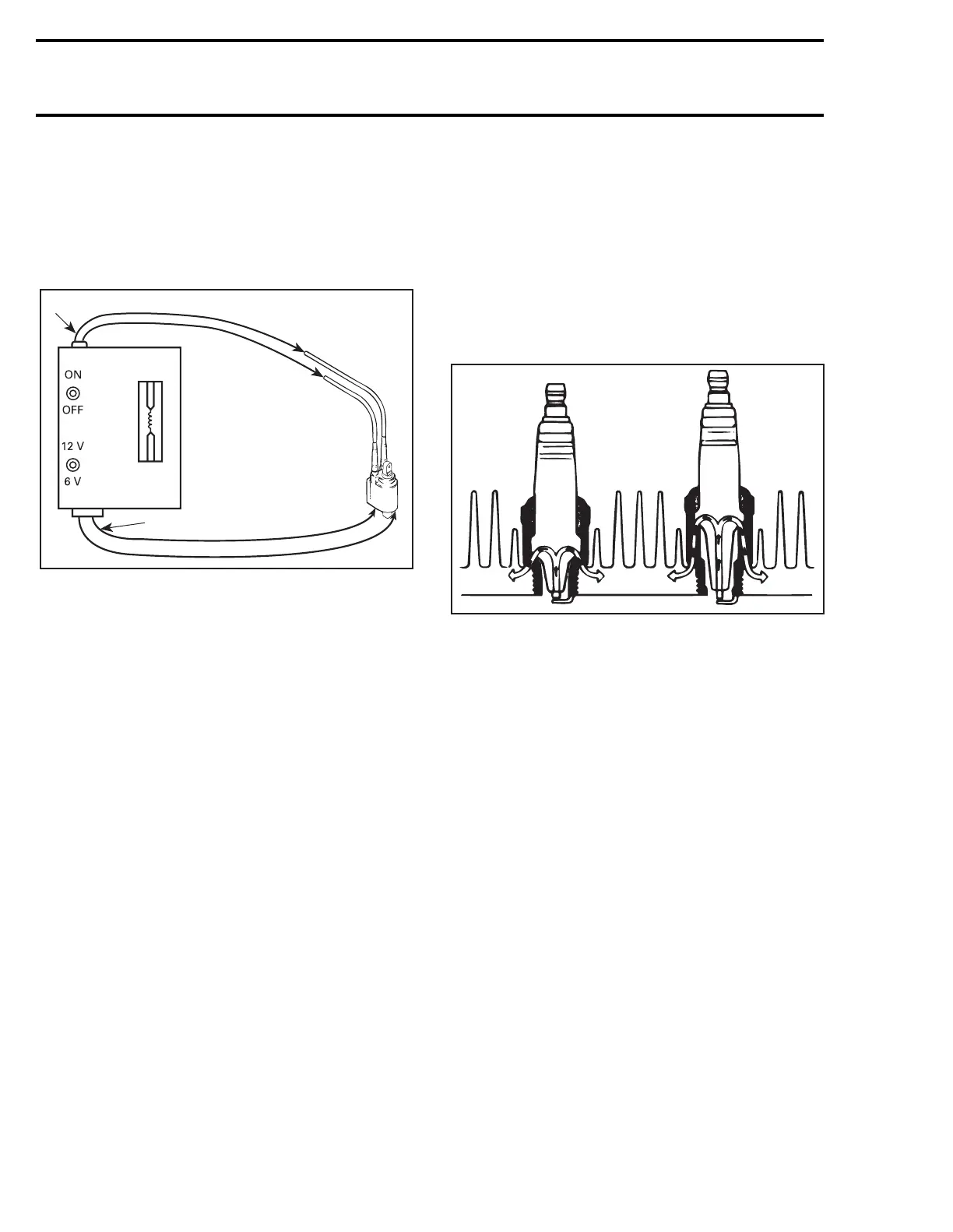

Heat Range

The proper heat range of the spark plugs is deter-

mined by the spark plugs ability to dissipate the

heat generated by combustion.

The longer the heat path between the electrode

tip to the plug shell, the hotter the spark plug op-

erating temperature will be — and inversely, the

shorter the heat path, the colder the operating

temperature will be.

A “cold” type plug has a relatively short insulator

nose and transfers heat very rapidly into the cylin-

der head.

Such a plug is used in heavy duty or continuous

high speed operation to avoid overheating.

The “hot” type plug has a longer insulator nose

and transfers heat more slowly away from its firing

end. It runs hotter and burns off combustion de-

posits which might tend to foul the plug during

prolonged idle or low speed operation.

1. Cold

2. Hot

CAUTION: Severe engine damage might occur

if a wrong heat range plug is used.

A too “hot” plug will result in overheating and pre-

ignition, etc.

A too “cold” plug will result in fouling or may create

carbon build up which can heat up red-hot and cause

pre-ignition or detonation.

A00E09A

12

Loading...

Loading...