Section 13 PROPULSION SYSTEM

Subsection 02 (JET PUMP)

SMR2003-040_13_02A.FM 13-02-13

Thrust Washer and Thrust Bearing

Visually inspect thrust washer no. 32, thrust bear-

ing no. 33 and their contact surface. Check for

scoring, pitting, flaking, discoloration or other evi-

dence of wear. For best inspection, use a 7X mag-

nifying glass to check wear pattern.

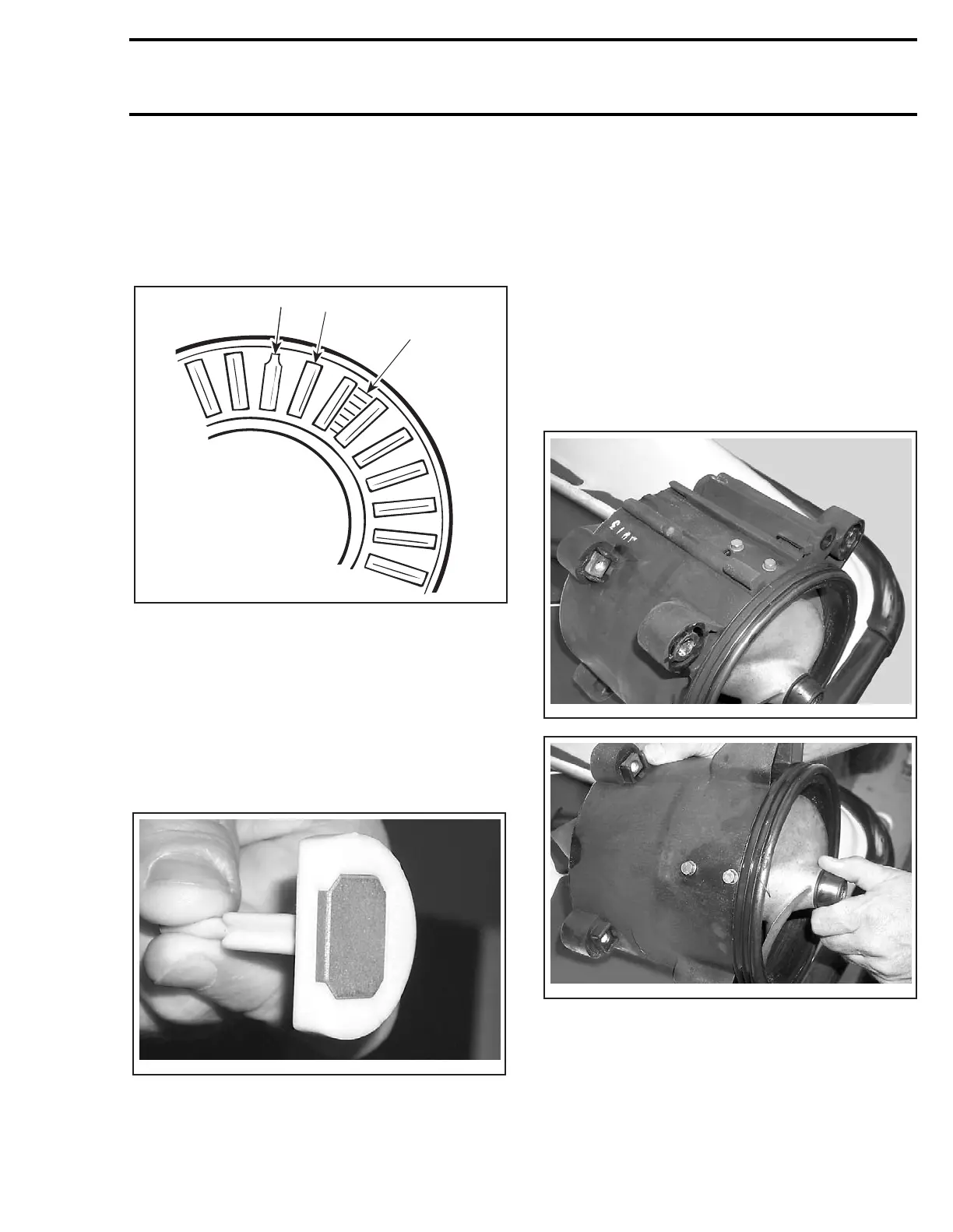

TYPICAL

1. Worn roller (trunnion worn on end roller)

2. Good roller (cylindrical shape)

3. Look for scoring on retainer

NOTE: When replacing either washer or bearing,

it is recommended to renew both.

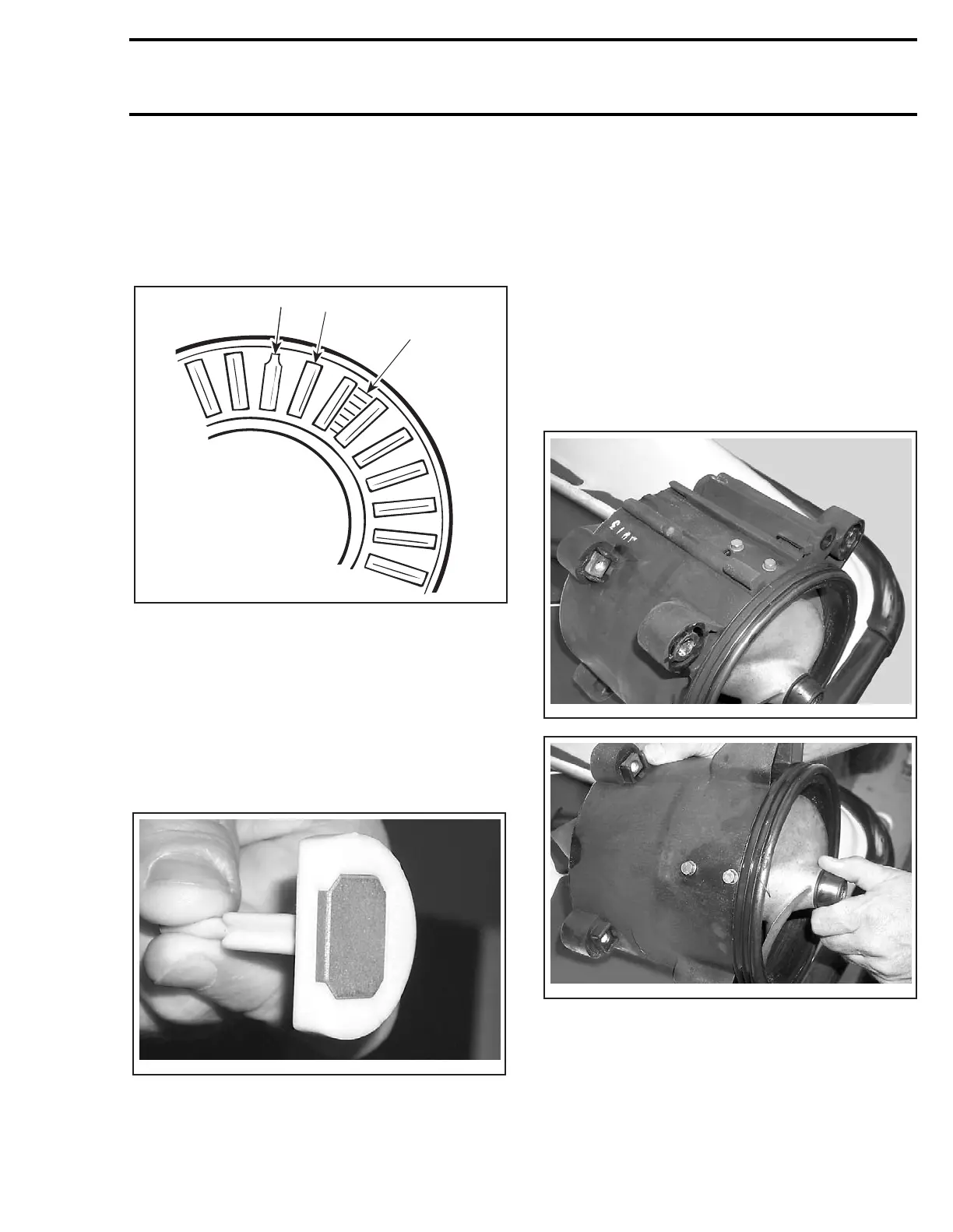

Anti-Rattle Pusher

Check for melted plastic around metal pad. If so,

replace it.

Check for excessive wear of pad.

Seal

Carefully inspect seal lips. Make sure that lips are

not worn, distorted, cracked or show signs of any

other damage. Replace after 150 hours even if it

seems good.

ASSEMBLY

Wear Ring

All Models except LRV DI

These models are equipped with large pumps. It

is important that the screws retaining wear ring to

housing are installed on this models.

All Models

To install ring in housing, use a square steel plate

of approximately 180 x 180 mm x 6 mm thick (7 x

7 in x 1/4 in) and a press.

F01J52A

1

2

3

F08J05A

F08J06A

F08J07A

Loading...

Loading...