Section 05 ENGINE (4-TEC)

Subsection 09 (ENGINE BLOCK)

SMR2003-021_05_09A.FM 05-09-3

GENERAL

When disassembling parts that are duplicated in

the engine, (e.g.: pistons, connecting rods etc.), it

is strongly recommended to note their position

(cylinder 1, 2 or 3) and to keep them as a “group”.

If you find a defective component, it would be

much easier to find the cause of the failure within

the group of parts (e.g.: you found a worn valve

guide. A bent spring could be the cause and it will

be easy to know which one among the springs is

the cause to replace it if you grouped them at dis-

assembly). Besides, since used parts have

matched together during the engine operation,

they will keep their matched fit when you reas-

semble them together within their “group”.

CRANKSHAFT LOCKING

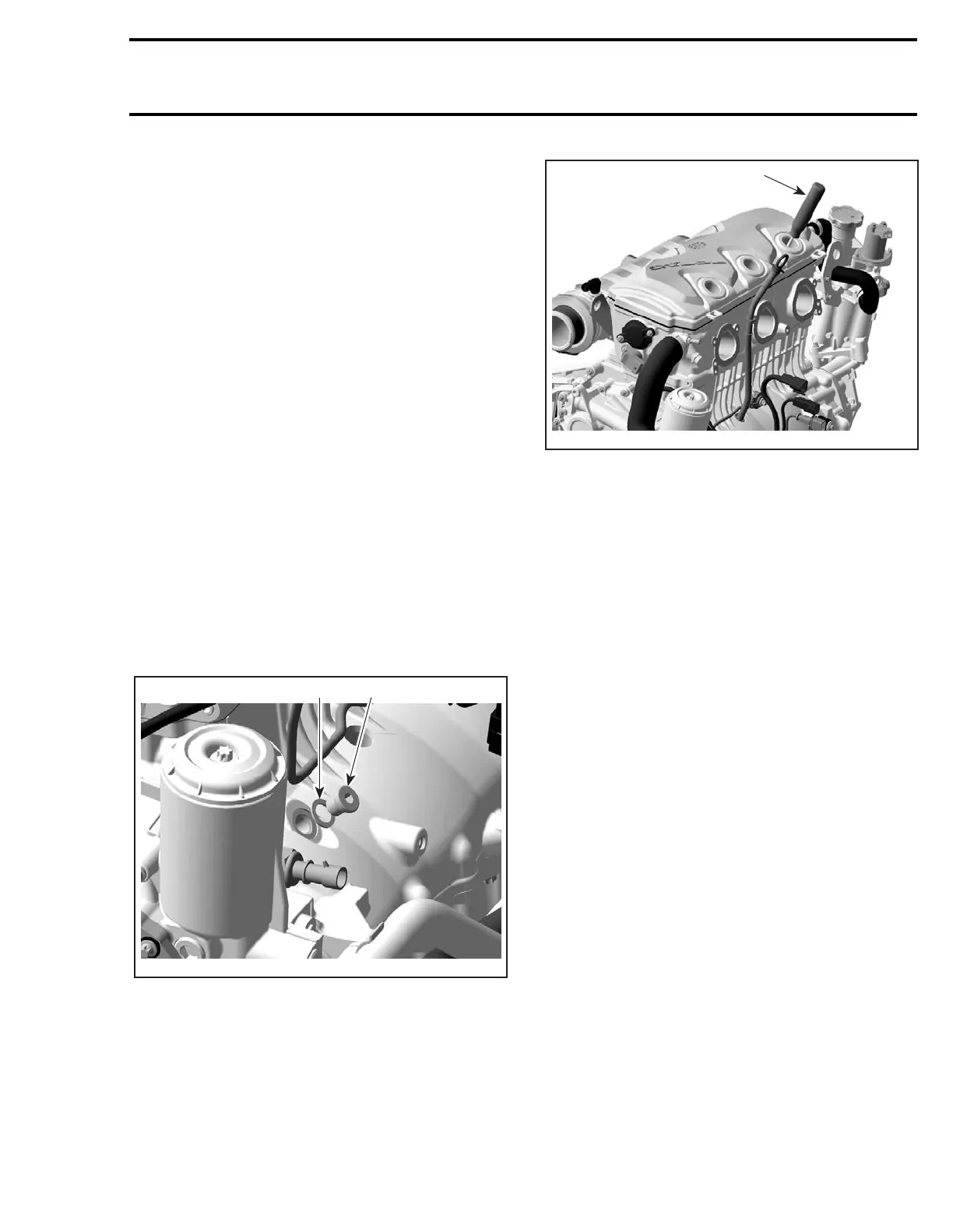

Remove:

– seat and vent tube support

– air intake manifold (refer to AIR INTAKE MANI-

FOLD REMOVAL in ENGINE section)

– fuel rail cover

– spark plugs

– plug screw.

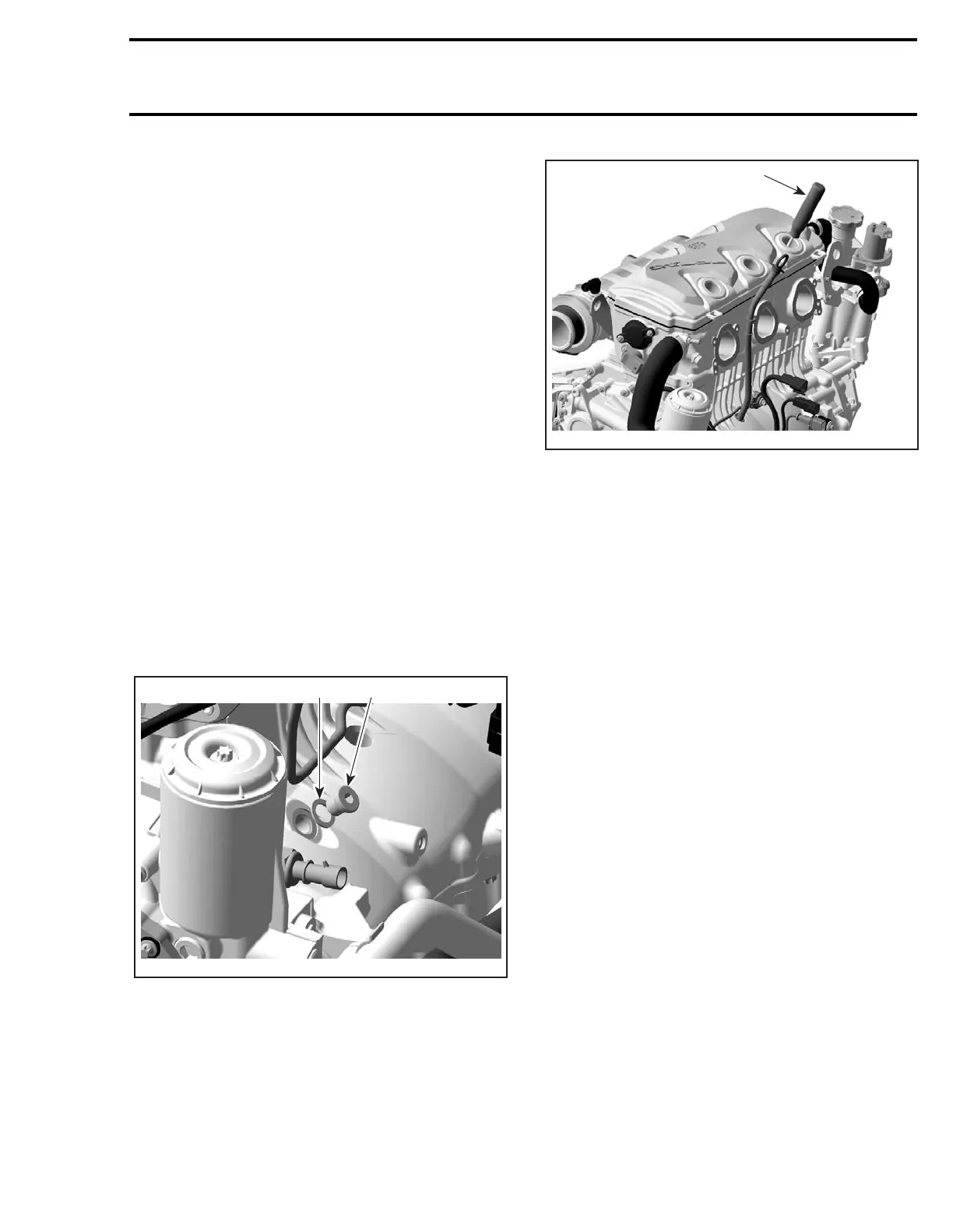

1. Plug screw

2. Gasket ring

Put a screwdriver or similar tool into the spark plug

hole of cylinder no. 3 and feel when the piston

reaches TDC.

1. Screwdriver

In this position, the crankshaft can be locked by

using crankshaft locking tool (P/N 529 035 821).

When finished, reinstall all removed parts.

CRANKSHAFT

Removal

Remove:

– engine oil

(refer to OIL CHANGE in LUBRICATION section)

– engine from vehicle

(refer to REMOVAL AND INSTALLATION)

– cylinder head

(refer to CYLINDER HEAD REMOVAL in CYLIN-

DER HEAD AND VALVES section)

– PTO housing

(refer to PTO HOUSING REMOVAL in PTO

HOUSING/MAGNETO section)

– starter gear

(refer to STARTER GEAR REMOVAL in PTO

HOUSING/MAGNETO section)

– starter drive ass’y

– oil suction pump with oil separator ass’y

(refer to SUCTION PUMP REMOVAL in LUBRI-

CATION section)

– engine mounting brackets

2

R1503motr04A

1

1

R1503motr03A

Loading...

Loading...