Section 12 ELECTRICAL SYSTEM

Subsection 04 (STARTING SYSTEM)

12-04-12 SMR2003-037_12_04A.FM

Overrunning Clutch

2-Stroke Engines

Pinion of overrunning clutch should turn smoothly

in clockwise direction, and should not slip in a

counterclockwise direction. If defective, replace.

Check pinion teeth for wear and damage. If defec-

tive, replace.

NOTE: Always check engine ring gear teeth for

wear and damage. If defective replace ring gear.

Refer to MAGNETO.

STARTER ASSEMBLY

All Engines

Reverse the order of disassembly to reassemble

starter. However, attention should be paid to the

following operations.

717 and 787 RFI Engines

Prior to assembling, coat sliding surfaces on arma-

ture shaft splines, overrunning clutch and bushing

(717 engine) with G.E. Versilube G 341 M or ESSO

Beacon 325 lubricant or equivalent.

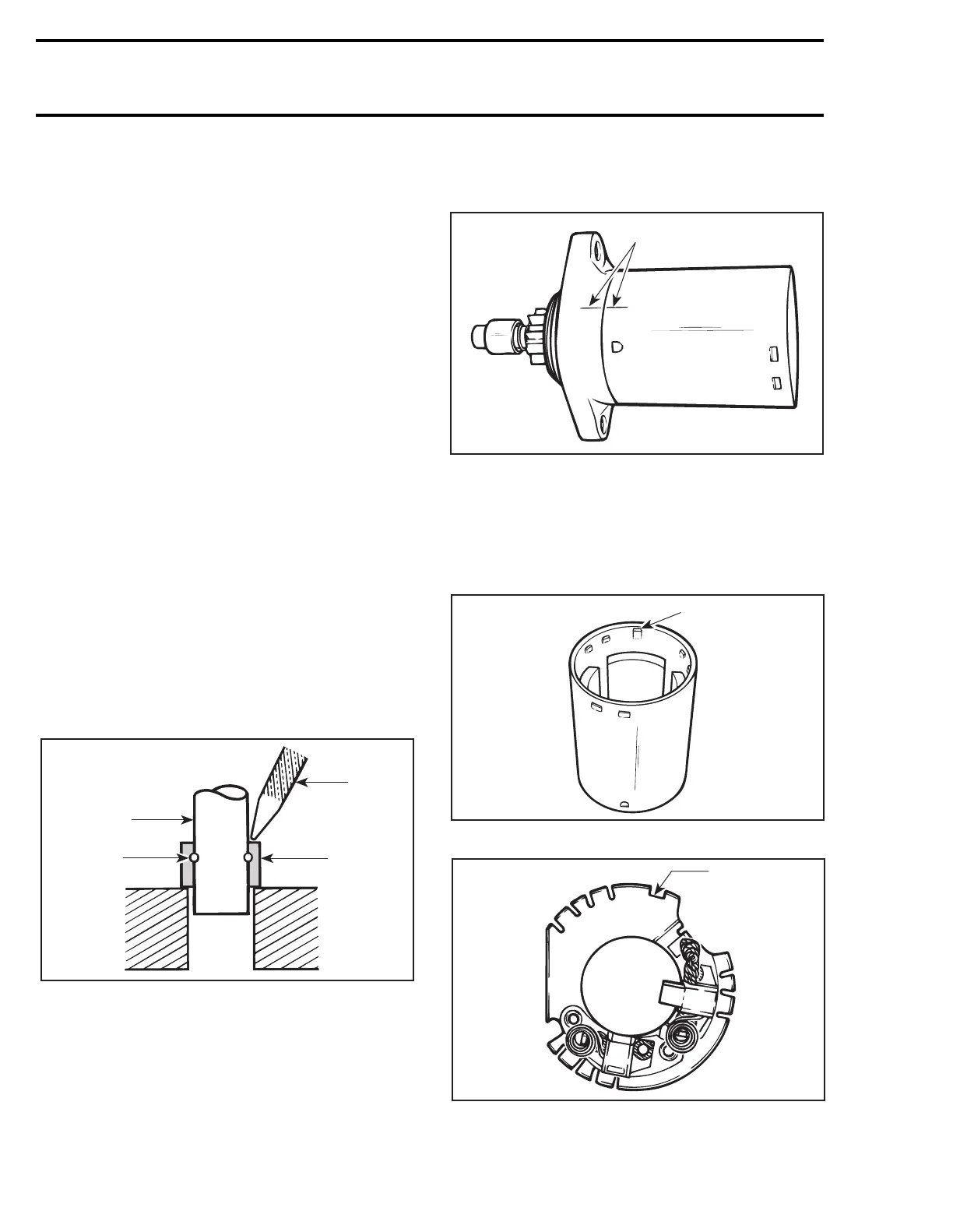

After placing pinion stop collar no. 7 on armature

shaft no. 11, fit circlip no. 6 into armature shaft,

then make sure that it is properly secured.

Slide stop collar no. 7 over circlip no. 6 and secure

in place by punching it at two or three places.

1. Armature shaft

2. Circlip

3. Pinion stop collar

4. Punch

Yoke Assembly and Clutch Housing

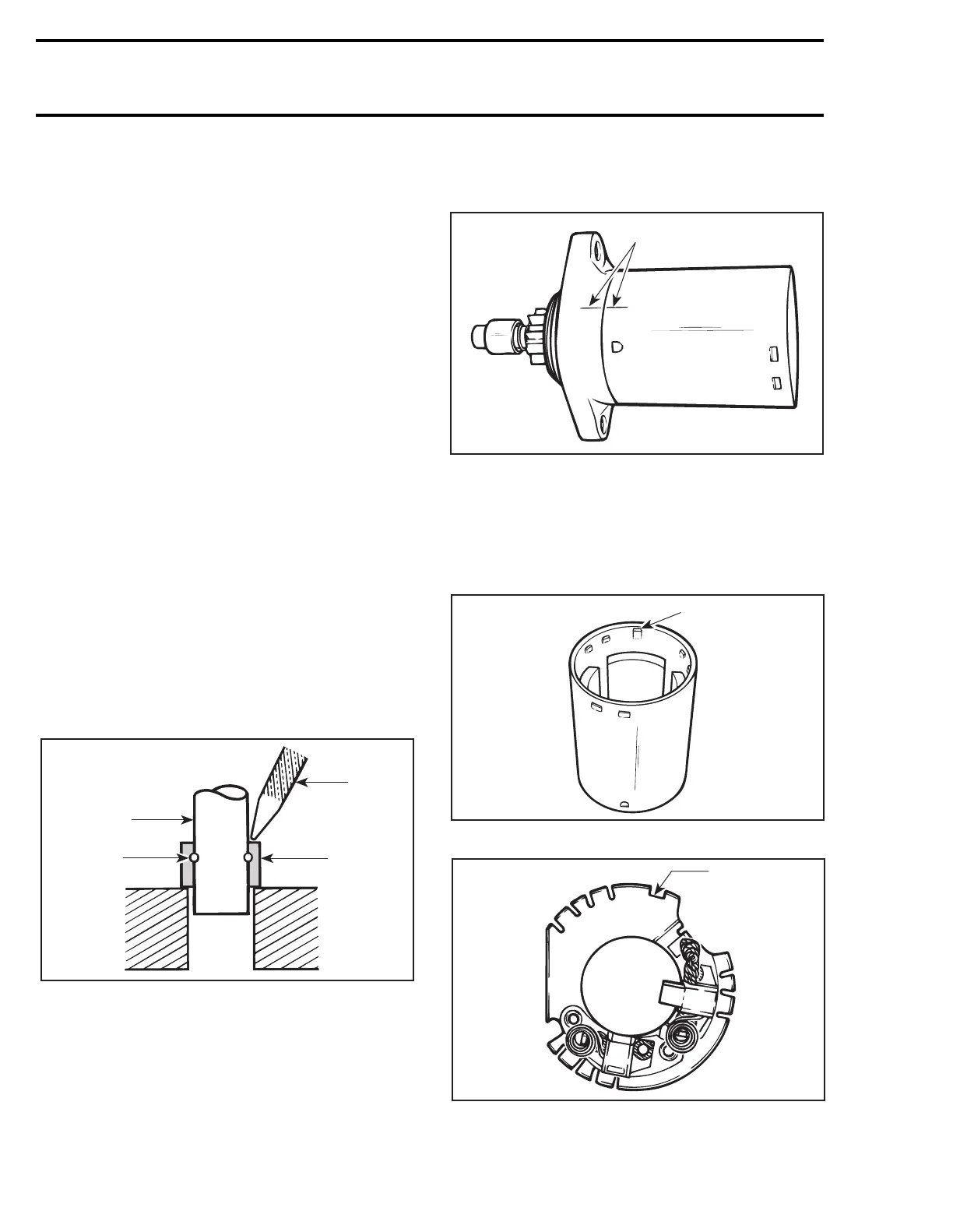

Align previously traced indexing marks.

TYPICAL

1. Align marks

Open brushes no. 4 and slide over commutator.

Align end frame locating notch with yoke locating

protrusion and properly sit brush holder no. 2 into

yoke no. 1.

1. Locating protrusion is the higher one

1. Brush holder locating notch

F01H0QA

1

F01H0SA

1

F01H0TA

1

Loading...

Loading...