Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 03 (COMPONENT INSPECTION AND ADJUSTMENT)

08-03-26 SMR2003_027 _08_03A.FM

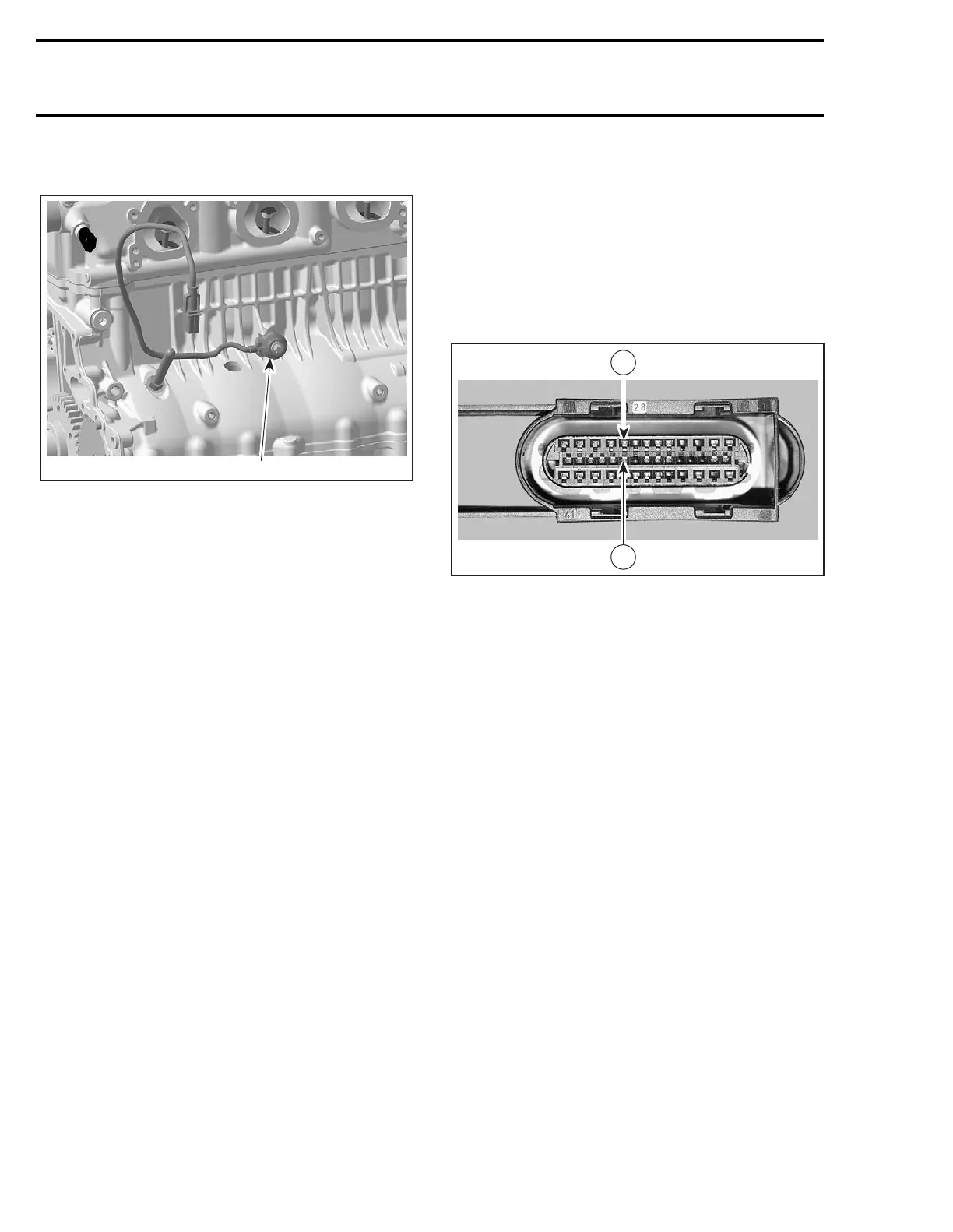

KNOCK SENSOR (KS)

1. Knock sensor (KS)

Dynamic Test

Using the vehicle communication kit (VCK) with

the B.U.D.S. software, monitor the knock sensor

using the Faults section.

Start the engine and bring engine RPM above

5000 RPM. If no fault code occurs, the knock sen-

sor is good.

Otherwise, do the following.

Ensure sensor and cylinder head contact surfaces

are clean and mounting bolt and washer are correct

and properly torqued down.

NOTE: It is necessary to remove intake manifold

to inspect contact surfaces. Refer to INTAKE SYS-

TEM section.

Check the knock sensor resistance.

Disconnect the connector from knock sensor har-

ness.

Static Resistance Test

Using a multimeter, check the resistance between

both terminals on the knock sensor harness side.

The resistance should be approximately

5 MΩ.

If resistance is not good, replace knock sensor.

If resistance is good, reconnect the knock sensor

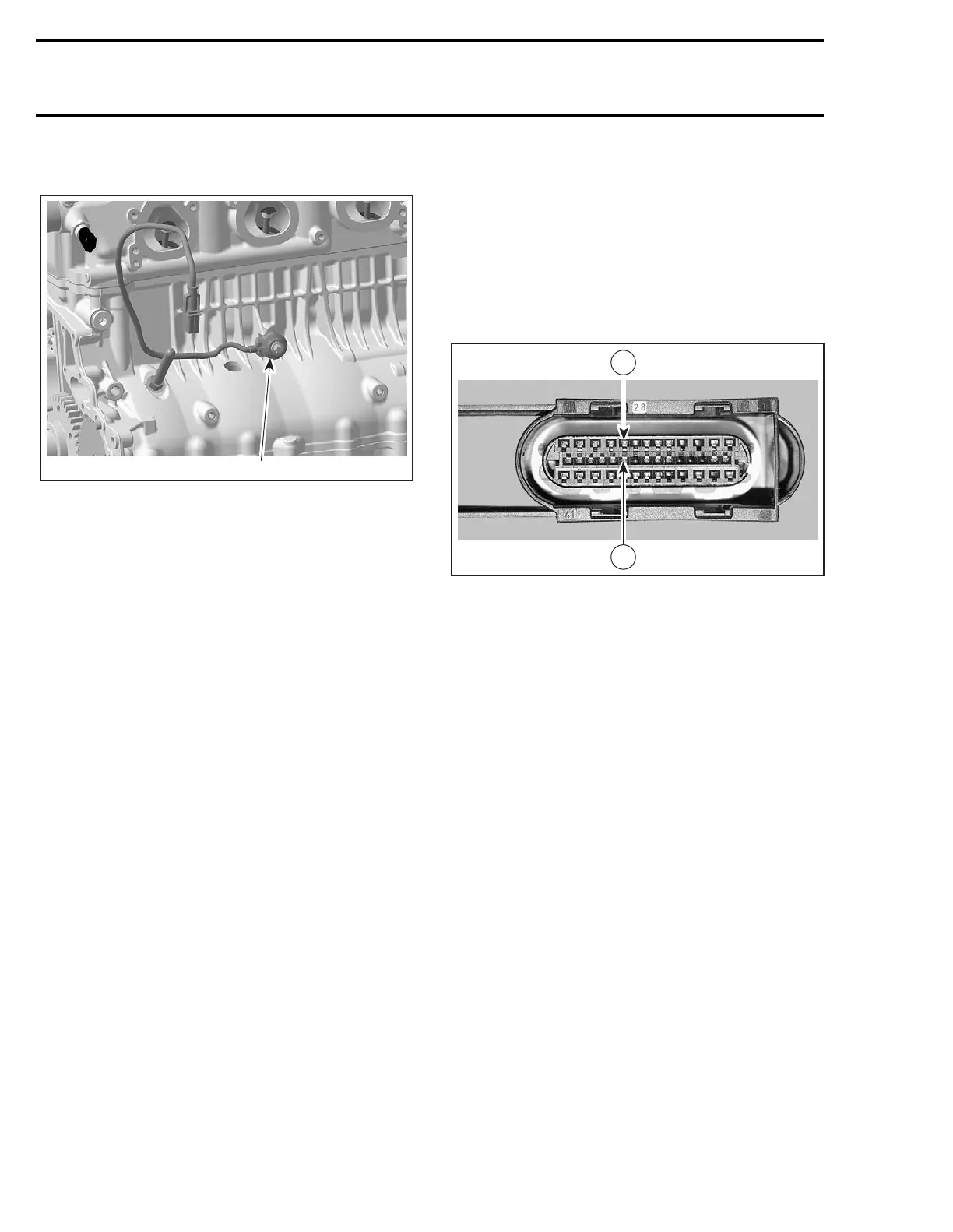

connector and disconnect the EMS ECU connec-

tor A from the EMS ECU.

Using a multimeter, recheck resistance value be-

tween terminals 9 and 23.

If wiring harness is good, try a new EMS ECU. Re-

fer to EMS ECU REPLACEMENT procedures else-

where in this section.

Otherwise, repair the connector or replace the wir-

ing harness between EMS ECU connector and

knock sensor.

Replacement

Remove the intake manifold. Refer to INTAKE

MANIFOLD REPLACEMENT in INTAKE section.

Unscrew and remove knock sensor.

Clean contact surface, apply Loctite 243 in thread-

ed hole then install the new knock sensor.

Torque screw to 24 N•m (18 lbf•ft).

CAUTION: Improper torque might prevent sen-

sor to work properly and lead engine to severe

damage of internal components.

Replug connector.

R1503motr188A

9

23

Loading...

Loading...