Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 03 (COMPONENT INSPECTION AND ADJUSTMENT)

SMR2003_027 _08_03A.FM 08-03-17

Connect the CPS, KS, OPS, and the MAPS to the

wiring harness.

Also connect now the MATS, TPS, OSPS, idle by-

pass and TOPS valve to the wiring harness.

Fix the wiring for the MATS with a locking tie to

support the cables.

1. Locking tie

Install all remaining parts, which has been removed.

THROTTLE POSITION SENSOR

(TPS)

General

The throttle position sensor (TPS) is a potentiom-

eter that sends a signal to the EMS ECU which is

proportional to the throttle shaft angle.

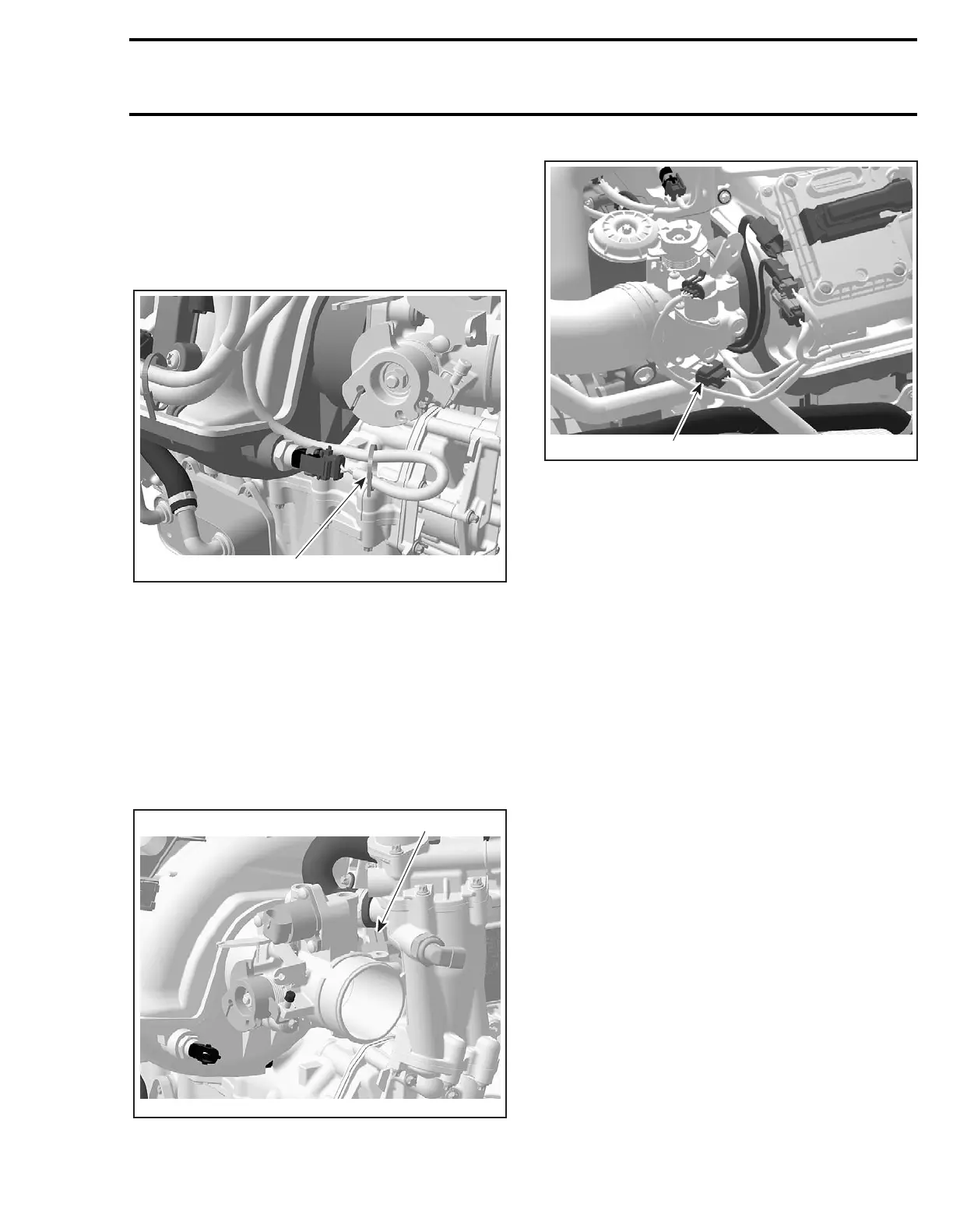

4-TEC ENGINES

1. Throttle position sensor (TPS)

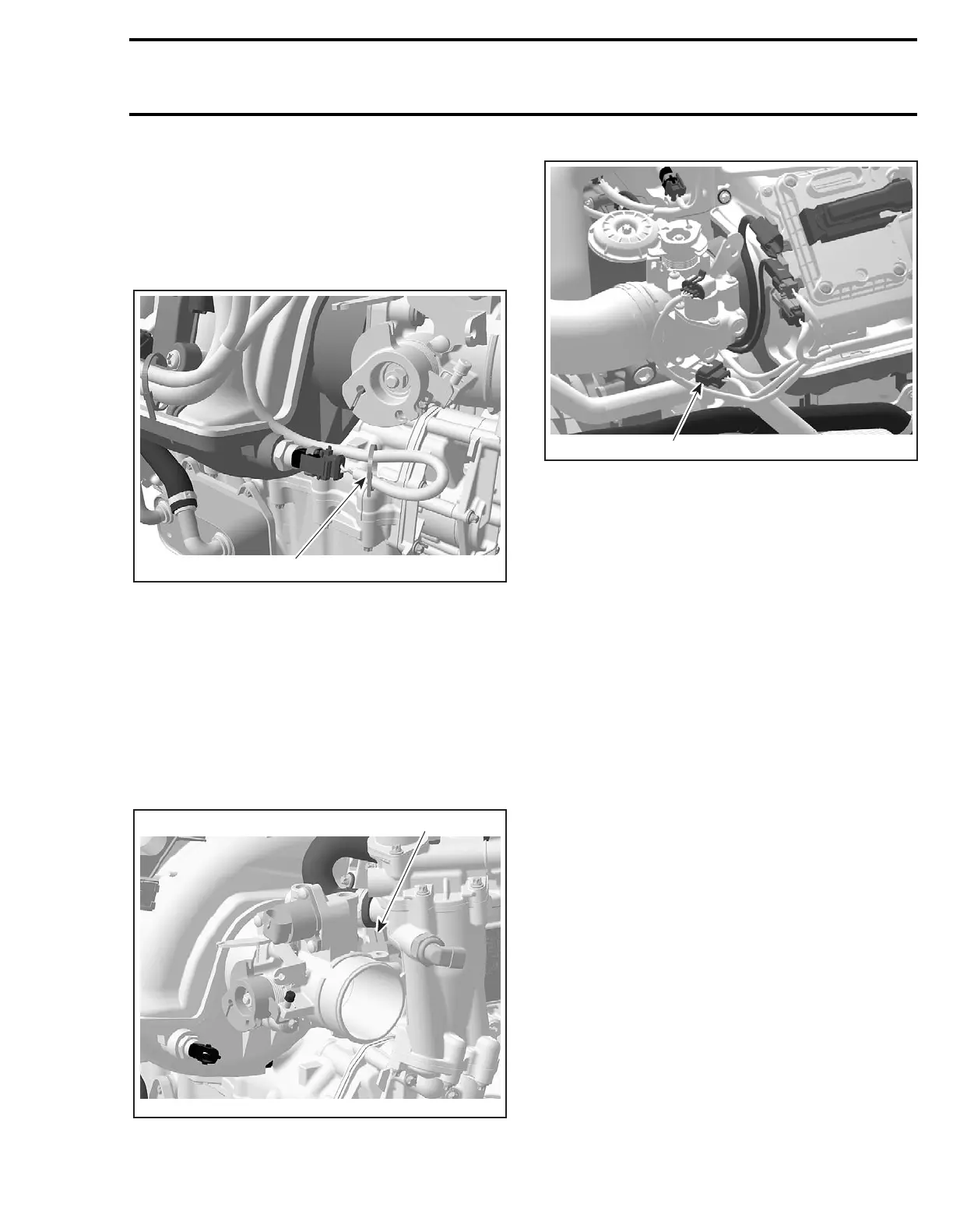

4-TEC SUPERCHARGED ENGINES

1. Throttle position sensor (TPS)

IMPORTANT: Prior to testing the TPS, ensure that

mechanical components/adjustments are adequate

according to THROTTLE BODY in AIR INDUCTION

SYSTEM above.

The EMS may generate several fault codes pertain-

ing to the TPS. Refer to SYSTEM FAULT CODES in

DIAGNOSTIC PROCEDURES section for more in-

formation.

Wear Test

While engine is not running, activate throttle and

pay attention for smooth operation without physi-

cal stops of the cable.

Using the vehicle communication kit (VCK) with

the B.U.D.S. software, use the Throttle Opening

display under Monitoring.

Slowly and regularly depress the throttle. Observe

the needle movement. It must change gradually

and regularly as you move the throttle. If the nee-

dle “sticks”, bounces, suddenly drops or if any dis-

crepancy between the throttle movement and the

needle movement is noticed, it indicates a worn

TPS that needs to be replaced.

1

R1503motr204A

1

R1503motr165A

1

R1503motr271A

Loading...

Loading...