Section 09 COOLING SYSTEM

Subsection 02 (CIRCUIT, COMPONENTS AND CARE)

09-02-18 SMR2003-029_09_02A.FM

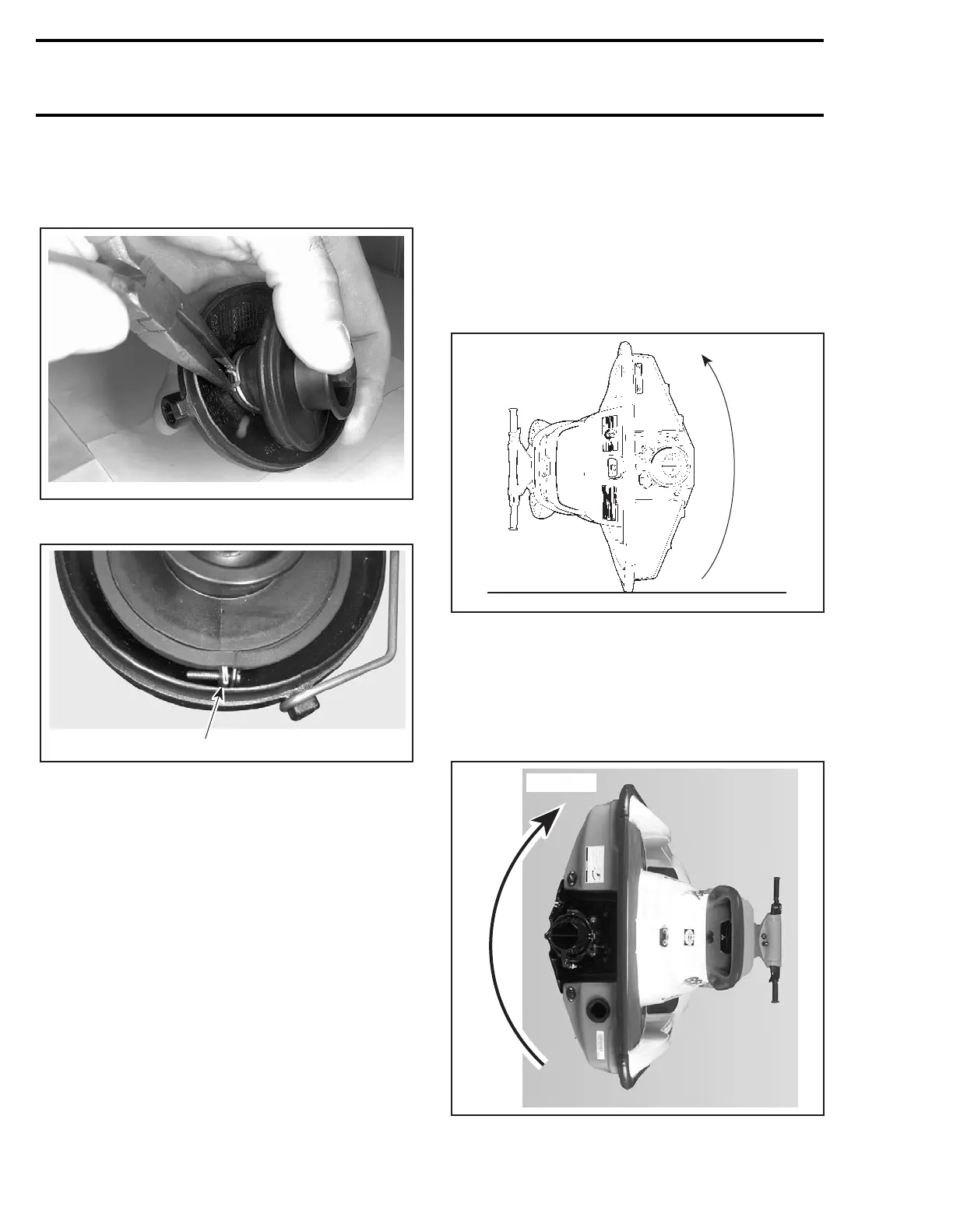

Pull the valve slightly. Using pliers, release the clamp

which retains the bellows no. 8.

Remove valve no. 7 and bellows no. 8.

Loosen clamp to separate valve from bellows.

1. Clamp

Inspection

Inspect parts for damage. Verify especially bellows

for cracks.

Assembly

Assembly is essentially the reverse of disassembly

procedures.

CARE

For flushing purposes, the cooling system is equipped

with either a fitting spigot or a hose adapter de-

pending upon the model.

For flushing operation, a coupler hose is available

(unnecessary for models with the hose adapter) to

connect to the fitting spigot. A garden hose is

used to flush the whole system by backwash. For

flushing procedure, refer to FLUSHING AND LU-

BRICATION.

For winterization of cooling system, refer to STOR-

AGE.

717 Engines

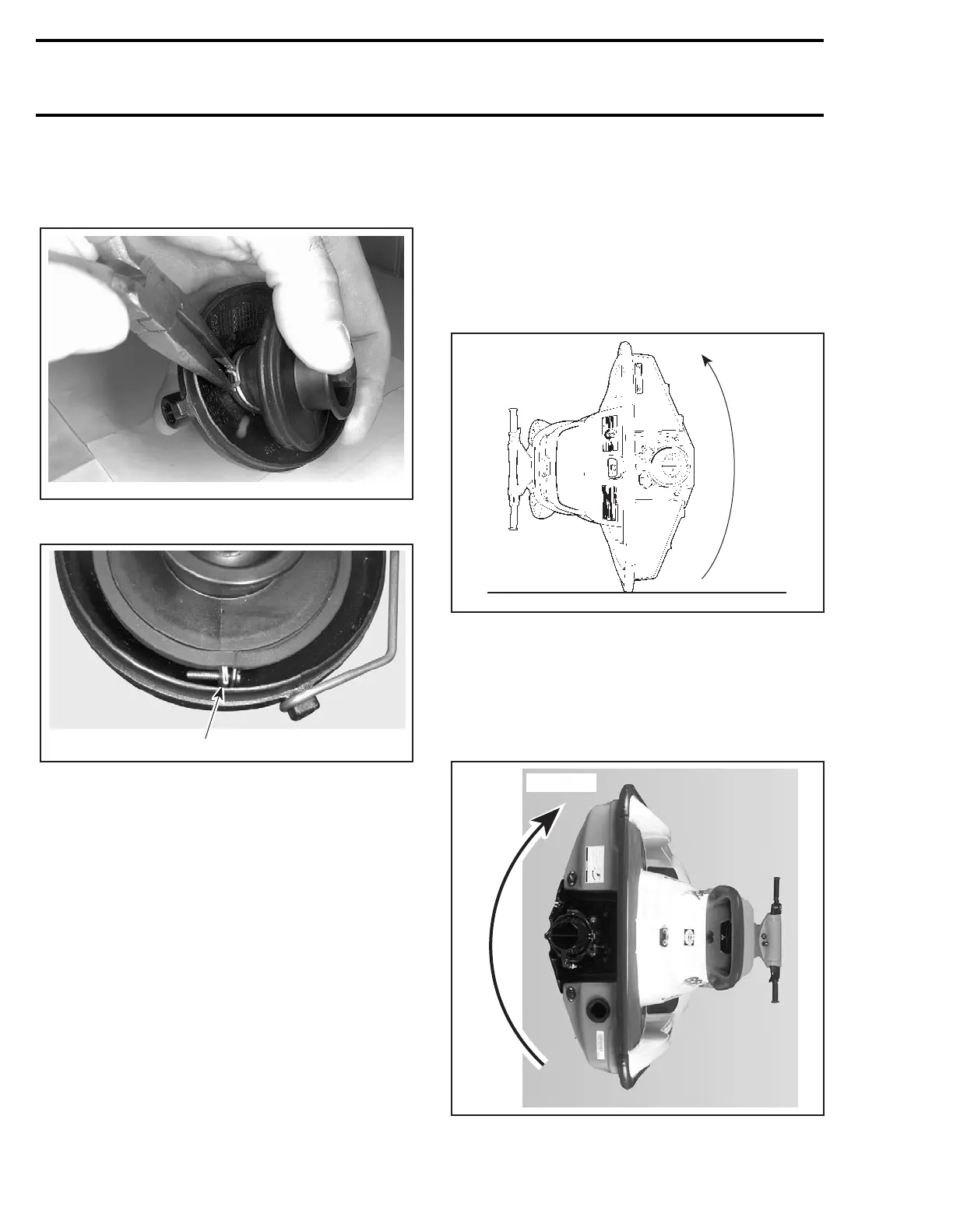

When servicing the hull, always rotate watercraft

counterclockwise (seen from the rear). Rotating

watercraft on the opposite side could allow resid-

ual water in tuned pipe to enter the engine and

cause damage.

Other Engines

When servicing the hull, always rotate watercraft

clockwise (seen from the rear). Rotating water-

craft on the opposite side could allow residual wa-

ter in tuned pipe to enter the engine and cause

damage.

TYPICAL

F01L45C

Max. 90°

F06L0GA

max. 90°

Loading...

Loading...