Section 12 ELECTRICAL SYSTEM

Subsection 04 (STARTING SYSTEM)

SMR2003-037_12_04A.FM 12-04-13

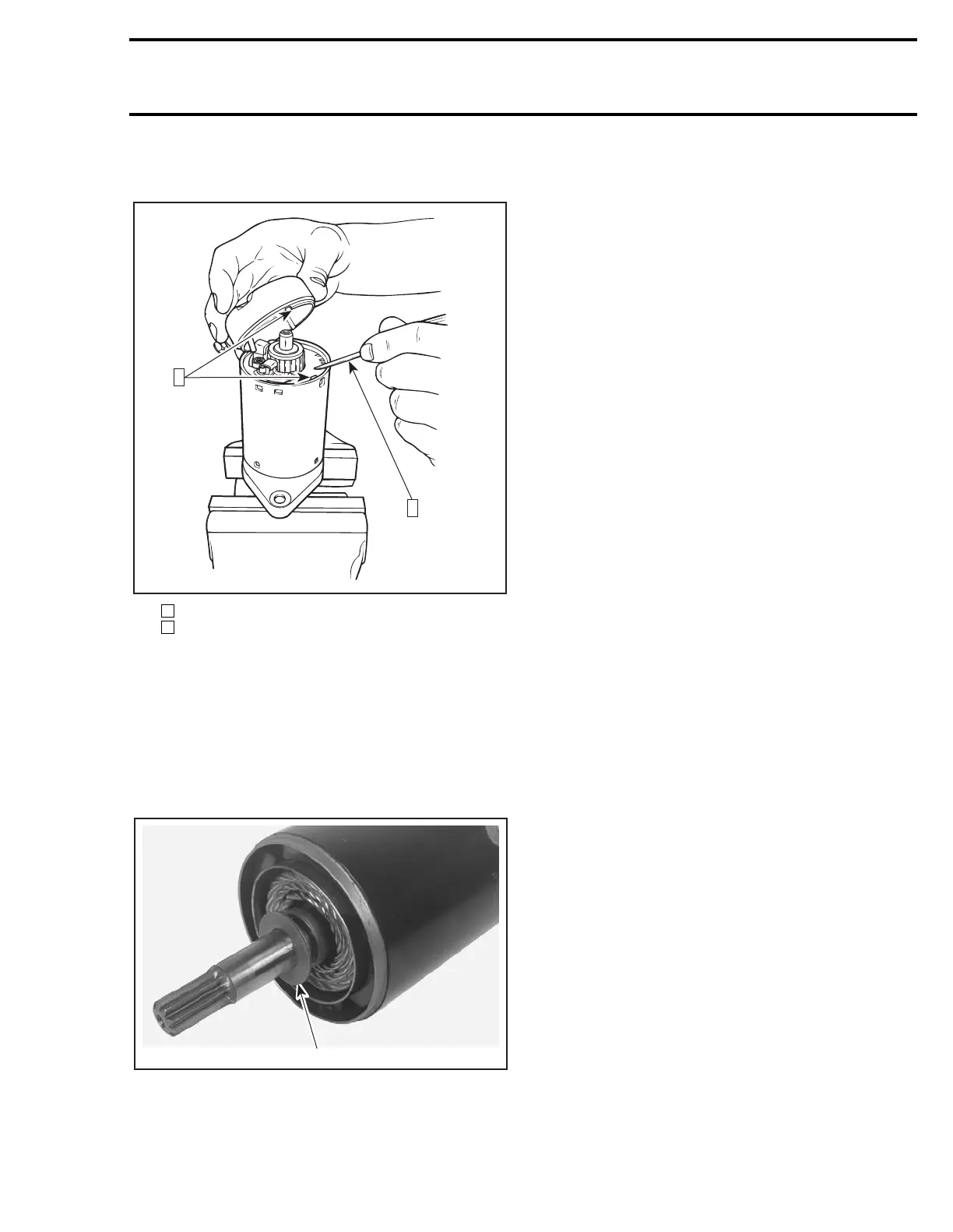

To ease end frame installation, retain brush holder

with a small screwdriver while installing end frame.

Step : Retaining brush holder with a screwdriver

Step : Align here

Align end frame notch with brush holder notch/

yoke protrusion.

CAUTION: Make sure end frame fits perfectly on

yoke.

947 DI Engines

Install new O-rings and gaskets.

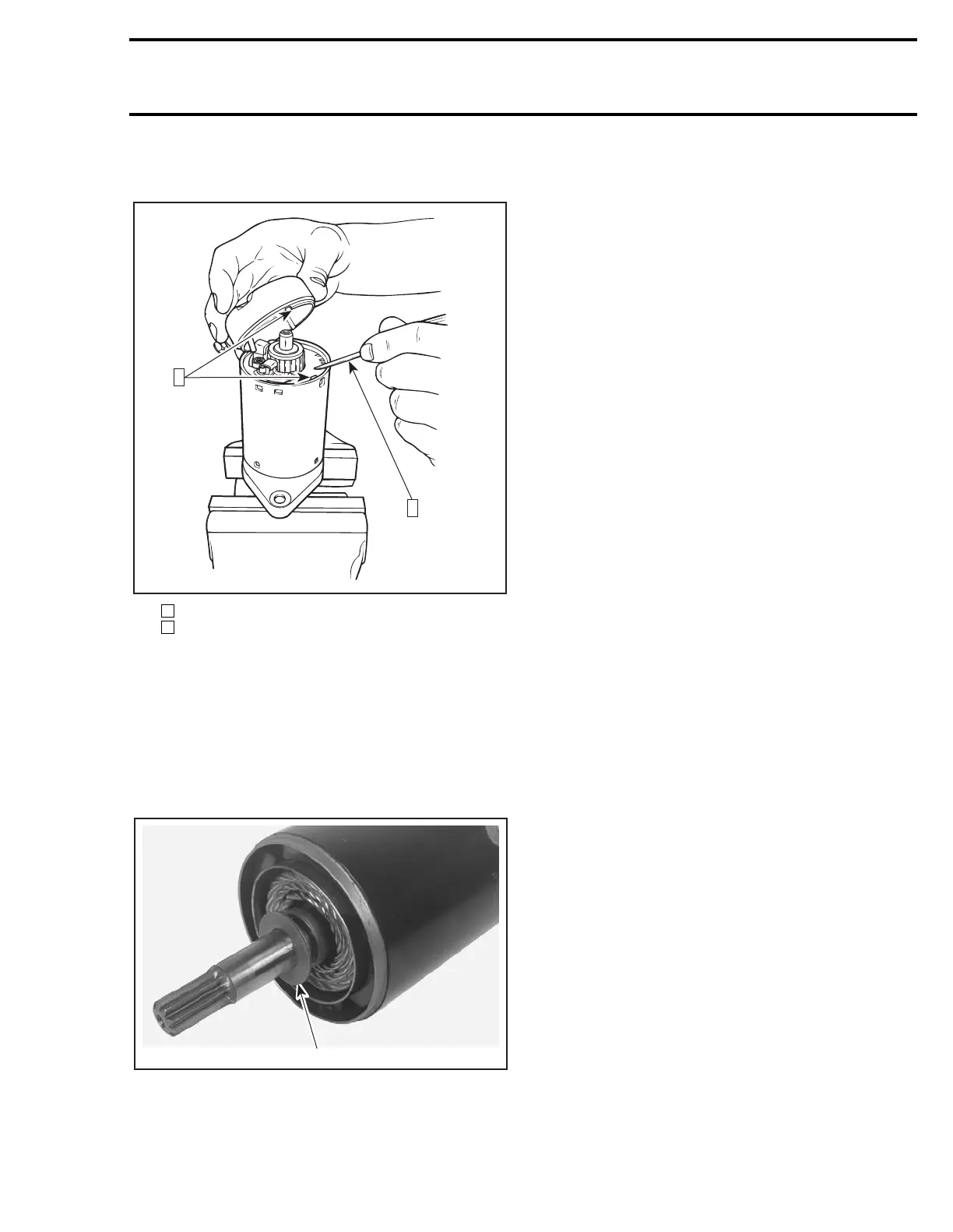

Insert thrust washers no. 19 onto armature shaft.

1. Thrust washers

Install the three washers no. 8 onto armature shaft.

When installing end covers no. 3 and no. 10 to

yoke, align index marks.

Apply Loctite 271 (red) on through bolts no. 5 and

torque to 6 N•m (53 lbf•in).

STARTER INSTALLATION

Installation is essentially the reverse of removal

procedure. However, pay particular attention to

the following.

Make sure that starter and engine mating surfaces

are free of debris. Serious trouble may arise if

starter is not properly aligned.

717 and 787 RFI Engines

Screw

Apply Loctite 243 (blue) on threads and torque start-

er screws no. 13 and no. 16 to 22 N•m (16 lbf•ft).

Nut

Connect the RED positive cable to the starter and

torque nut no. 17 to 6 N•m (53 lbf•in). Apply di-

electric grease on terminal and nut.

F01H0UA

2

1

1

2

F06H1HA

1

Loading...

Loading...