Section 09 COOLING SYSTEM

Subsection 02 (CIRCUIT, COMPONENTS AND CARE)

09-02-20 SMR2003-029_09_02A.FM

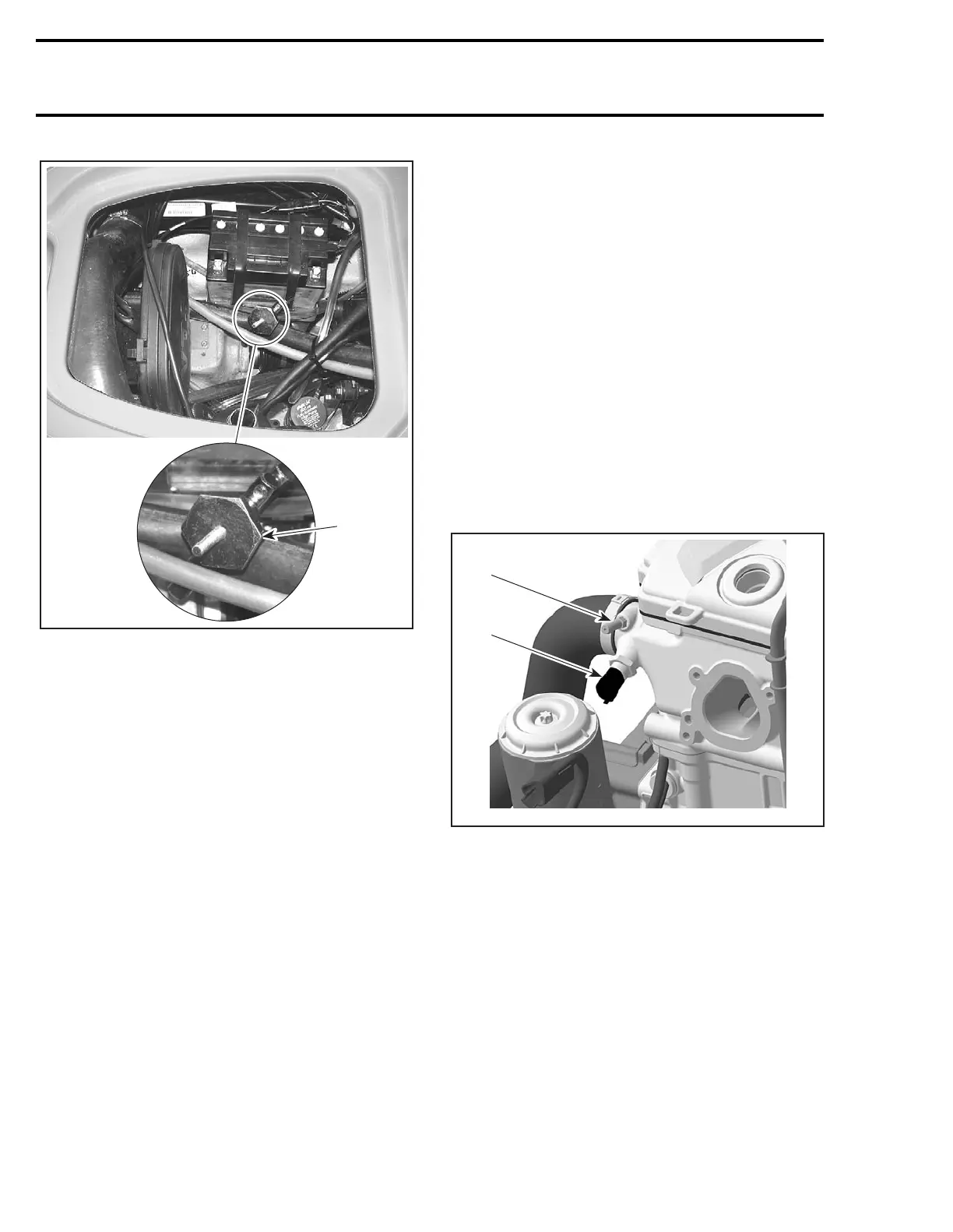

947 DI ENGINES — XP DI MODELS

1. Hose pincher on water supply hose

CAUTION: When finished towing the watercraft,

the hose pincher must be removed before oper-

ating it.

1503 Engines

CIRCUIT

Closed Loop System

A closed loop cooling system is utilized on the

1503 4-TEC engines, which offers an efficient en-

gine cooling while keeping dirt and salt water out

of the cooling system. This system keeps the tem-

perature constant and prevents internal engine

corrosion.

A separate coolant expansion tank ensures that

enough engine coolant is in the circuit during any

operating condition.

The coolant flow comes from the coolant pump

impeller into the engine block. It goes around the

cylinders and straight up to the cylinder head. A

smaller quantity of engine coolant enters the en-

gine block on the exhaust side for a better cooling.

In the cylinder head the water channels flow

around the exhaust and then the intake valves and

leave the engine through a large hose. From there

the coolant goes back to the water pump housing

and depending on the engine temperature, it

flows through the thermostat directly back to the

water pump impeller, or it takes its way through

the ride plate which operates as a heat exchanger.

A smaller quantity of engine coolant is also direct-

ed towards the oil cooler, which is located under

the air intake manifold, to increase cooling effi-

ciency.

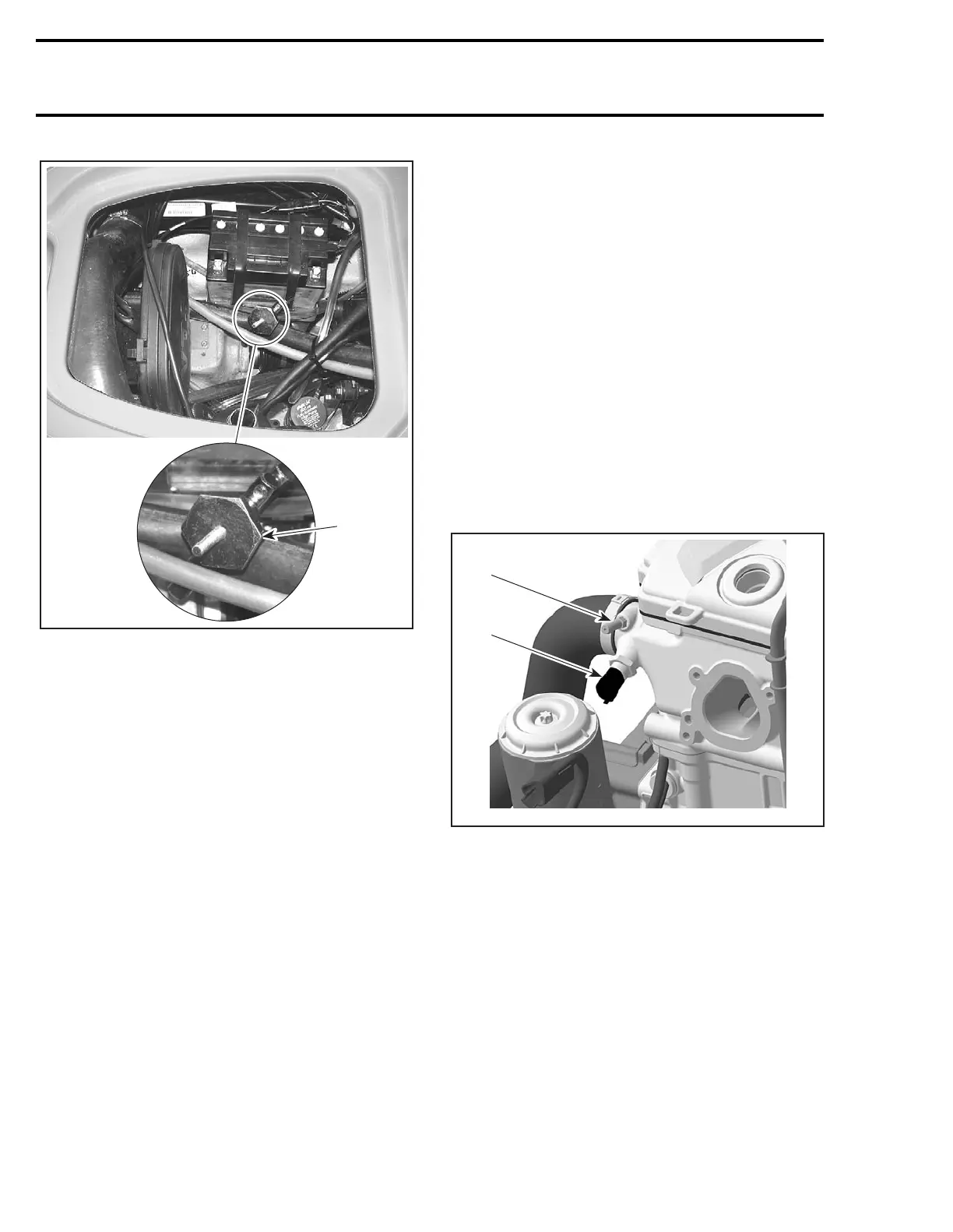

Coolant temperature sensor and bleed nipple are

located on the cylinder head.

1. Bleed nipple

2. Coolant temperature sensor (CTS)

CAUTION: Never modify cooling system ar-

rangement, otherwise serious engine damage

could occur.

Pressure Cap

Check if cap pressurize the system. if not, install

a new 90 kPa (13 PSI) cap (do not exceed this pres-

sure).

1

F18E0XA

2

Loading...

Loading...