Section 05 ENGINE (4-TEC)

Subsection 07 (LUBRICATION SYSTEM)

SMR2003-019_05_07A.FM 05-07-11

1. Pittings on the teeth

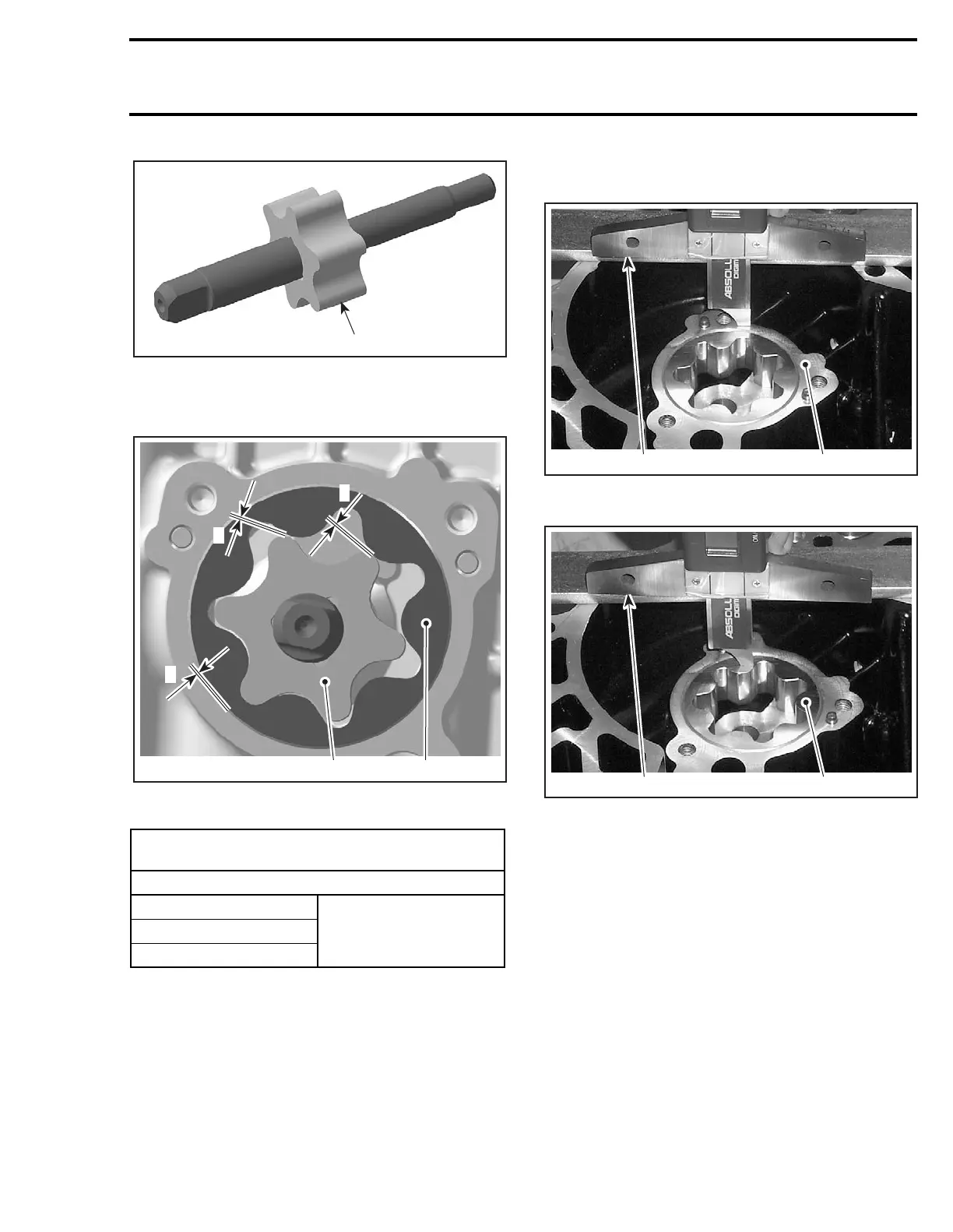

Using a feeler gauge, measure the clearance be-

tween inner and outer rotors.

1. Outer rotor

2. Inner rotor

If clearance between inner and outer rotors ex-

ceeds the tolerance, replace coolant/oil pump shaft

assembly. Ensure to also check oil pump housing

and cover and replace if damaged.

If clearance between outer rotor and its bore in oil

pump exceeds the tolerance, replace the complete

oil pump and the PTO housing.

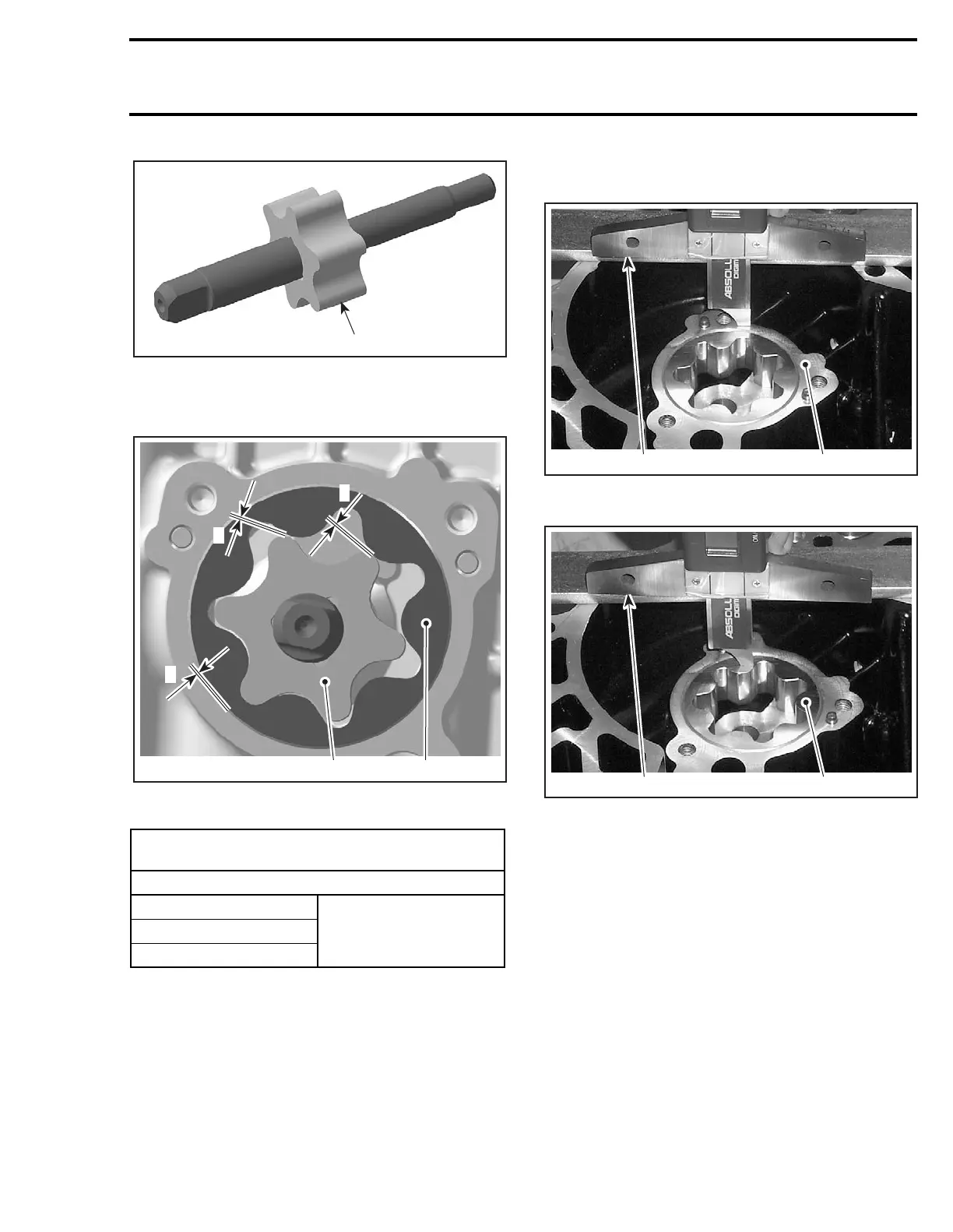

Using a vernier depth gauge, measure side wear as

shown.

1. PTO housing surface

2. Vernier depth gauge

1. Oil pump outer rotor surface

2. Vernier depth gage

Difference between pump housing and outer rotor

should not exceed 0.1 mm (.004 in). If so, replace

replace the complete oil pump assembly.

NOTE: When the axial clearance of the oil pump

shaft assembly increases, the oil pressure de-

creases.

Check the inside of oil pump housing and its cover

for scoring or other damages and replace if dam-

aged.

OUTER AND INNER ROTOR CLEARANCE

mm (in)

SERVICE LIMIT

A

0.25 mm (.009 in)B

C

1

R1503motr129A

2

R1503motr130A

1

C

A

B

1

R1503motr131A

2

R1503motr132A

12

Loading...

Loading...