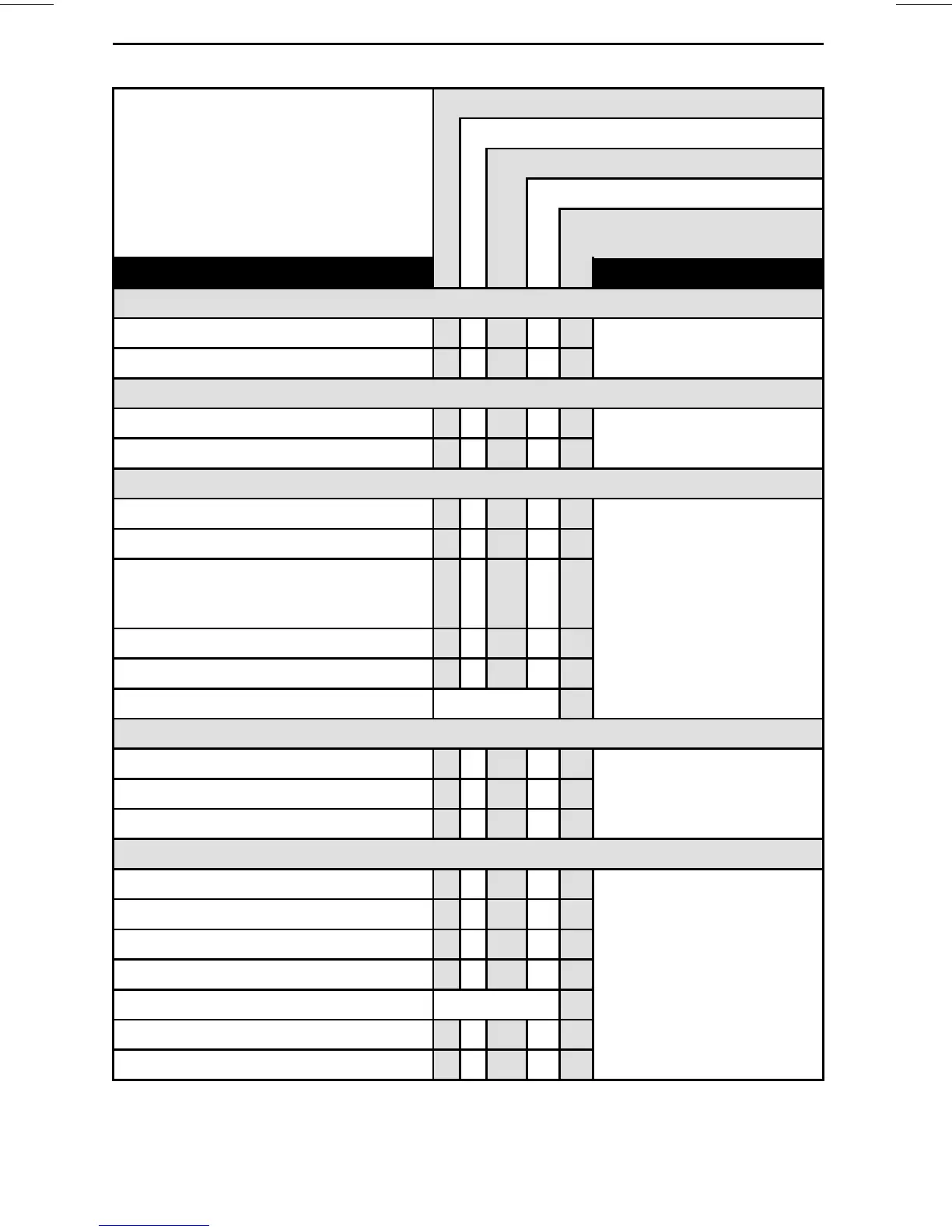

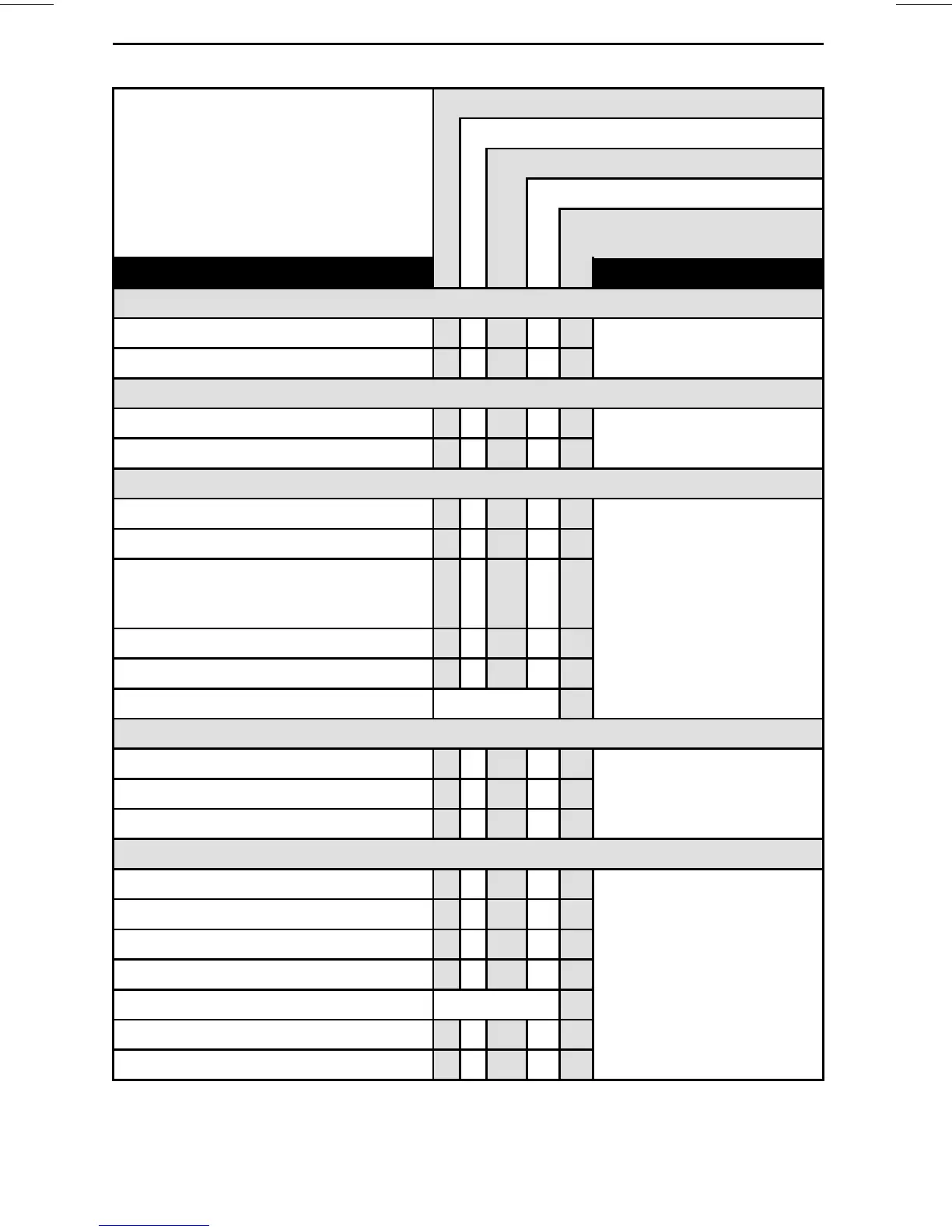

MAINTENANCE SCHEDULE

25 HOURS OR 3 MONTHS

50 HOURS OR 6 MONTHS

100 HOURS OR 1 YEAR

200HOURSOR2YEAR

A: ADJUST

C: CLEAN

I: INSPECT

L: LUBRICATE

R: REPLACE

O: OPERATOR

D: DEALER

TO BE PERFORMED BY

PART/TASK NOTE

AIR INTAKE SYSTEM

Air intake silencer I, C D

Blow-by valve hose I, C D

—

ELECTRONIC MANAGEMENT SYSTEMS

EMS sensors I D

Fault codes (ECM, iBR, iS, Cluster) I D

—

ELECTRICAL SYSTEM

Spark plugs I R D

Ignition coils I, L D

Electrical connections and fastening (ignition

system, starting system, fuel injectors, fuse

boxes etc.)

ID

Engine cut-off switch I D

Monitoring beeper I D

Battery and fasteners I

(5)

D

(5) Inspect once a month. Add

electrolyte as required.

STEERING SYSTEM

Steering cable and connections I D

Steering nozzle bushings I D

O.T.A.S.

(6)

ID

(6) Inspect operation

PROPULSION SYSTEM

Carbon ring and rubber boot (drive shaft) I D

Impeller boot I D

Impeller shaft seal, sleeve and O-ring I

(4)

D

Drive shaft/impeller splines I, L D

Sacrificial anode (if so equipped) I

(8)

D

Impeller and impeller wear ring clearance I D

Pump mounts I D

(4) At storage period or

after 100 hours of use

whichever comes first.

(8) Inspect each month (more

often in salt water use) and

change when necessary.

128

______________

Loading...

Loading...