BIESSE S.p.A. Woodworking Machinery

(l107h050.fm-141101)

&KDSWHU 0DLQWHQDQFH

This chapter contains the information that is required to keep the machine in perfect working order.

'$1*(5

%HIRUHFDUU\LQJRXWDQ\PDLQWHQDQFHLQWHUYHQWLRQVRUUHSDLUVWRWKHPDFKLQHXQOHVV

RWKHUZLVHVSHFLILHGVZLWFKRIIWKHPDFKLQHDQGEOHHGWKHDLUIURPWKHSQHXPDWLFV\VWHPE\

DGMXVWLQJWKHFXWRXWYDOYHUHI%SDJH8VHWKHSDGORFNVVXSSOLHGWRORFNWKHPDLQ

VZLWFKUHI$SDJHDQGWKHFXWRXWYDOYHWRSUHYHQWDQ\RQHIURPUHVWDUWLQJWKH

PDFKLQH$OVRPDNHVXUHWKDWDOOPDFKLQHPHFKDQLFDORUJDQVDUHLQWKHVWDQGE\SRVLWLRQ

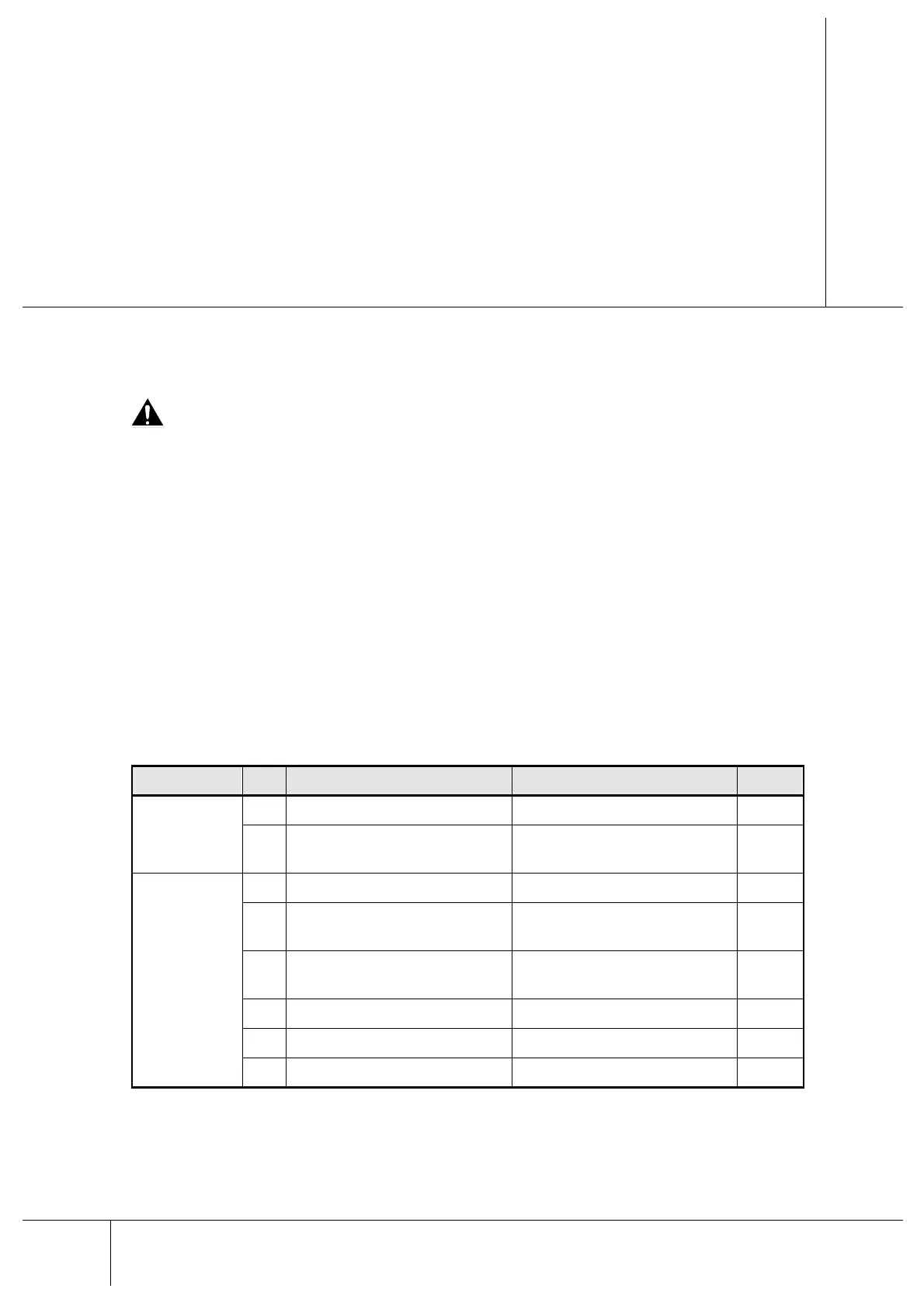

0DLQWHQDQFH,QWHUYHQWLRQ6XPPDU\DQG)UHTXHQF\

The following table contains a summary of all foreseen maintenance interventions as well as the

frequency with which they should be effected. Take into account that frequency has been

evaluated according to a 5-day working week of 8 hours per day and to normal operating

conditions. The letter in the 5HI. column is used to locate the points of the machine as illustrated

on page 7 - 2, which require maintenance. The 3DJH column shows, for those interventions that

require it, the number of the page where the intervention procedure is explained.

)UHTXHQF\ 5HI 3DUW 2SHUDWLRQ 3DJH

(YHU\

'D\

Whole machine Cleaning 7 - 2

$ FR Unit Check condensation in tray;

drain if necessary

7 - 3

(YHU\

:HHN

% Blade carriage Clean the guides 7 - 2

& Blade carriage and pushing

device carriage

Clean the racks 7 - 2

' Presser Clean the racks with

compressed air

( Control panel Clean the filters 7 - 3

) Electrical cabinet Clean the filters 7 - 4

* Electrical cabinet Clean the air conditioner 7 - 4

Loading...

Loading...