18 DUSTHUNTER T · Operating Instructions · 8012428 V 2.0 · © SICK MAIHAK GmbH Germany

Product Description

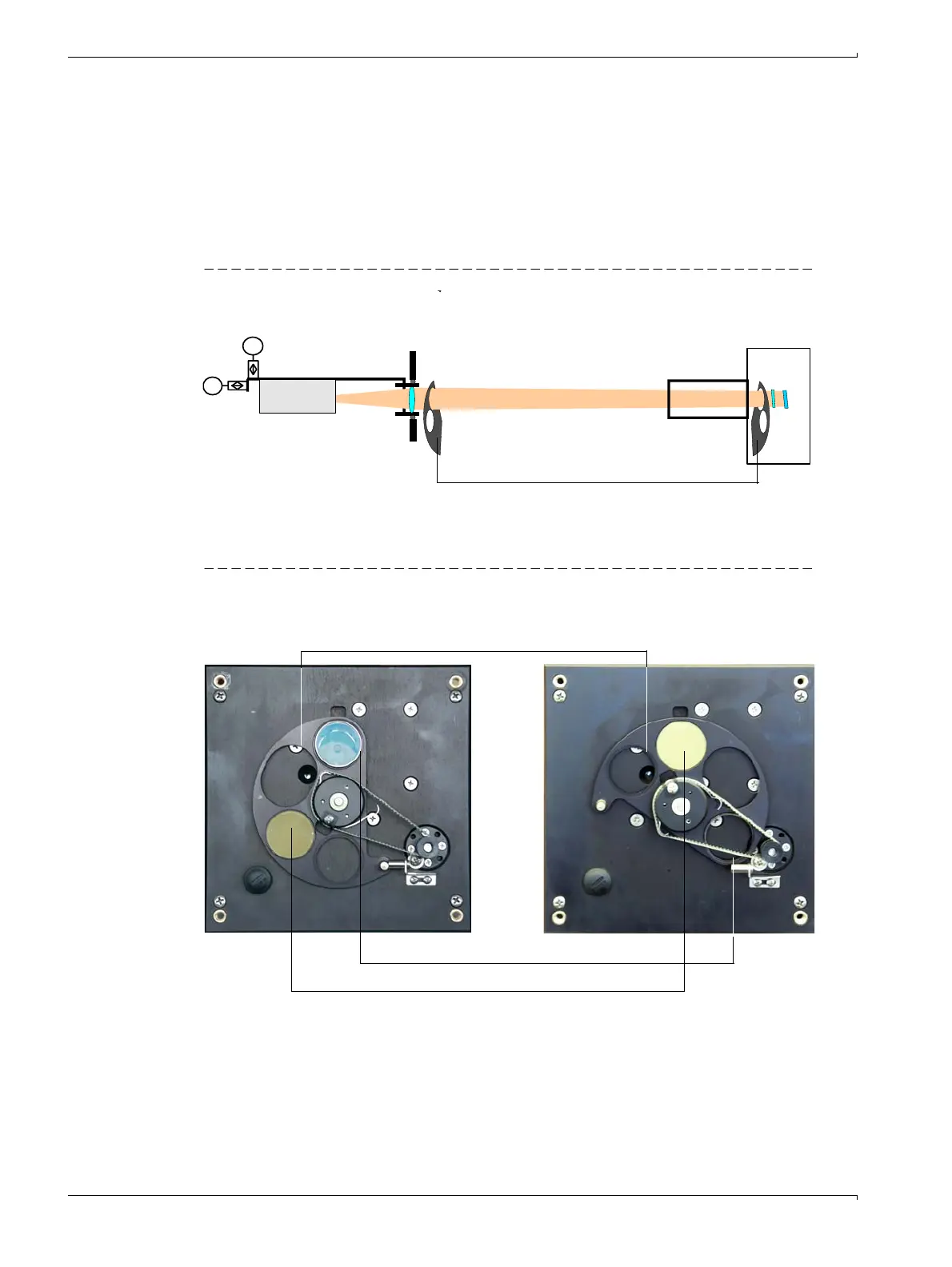

Contamination measurement (not on DUSTHUNTER T50)

The glass panes positioned in the sender beam during normal measurement are swiveled

away during contamination determination. The measured value determined and the value

measured at scaling (

→

p. 61, §4.2.3) are used to calculate a control factor. This serves to

completely compensate any cContamination that occurs.

Contamination is determined on one side on the DUSTHUNTER T100 (swivel plate only on

the sender/receiver unit) and on both sides on the DUSTHUNTER T200 (swivel plate also

on the reflector).

Figure 5 Contamination measurement principle (on both sides)

The measuring system outputs status "Malfunction" (the value for Live Zero on the analog

output) when a type-dependent contamination value is exceeded (

→

p. 30, §2.3.1 and

→

p. 108, §7.1).

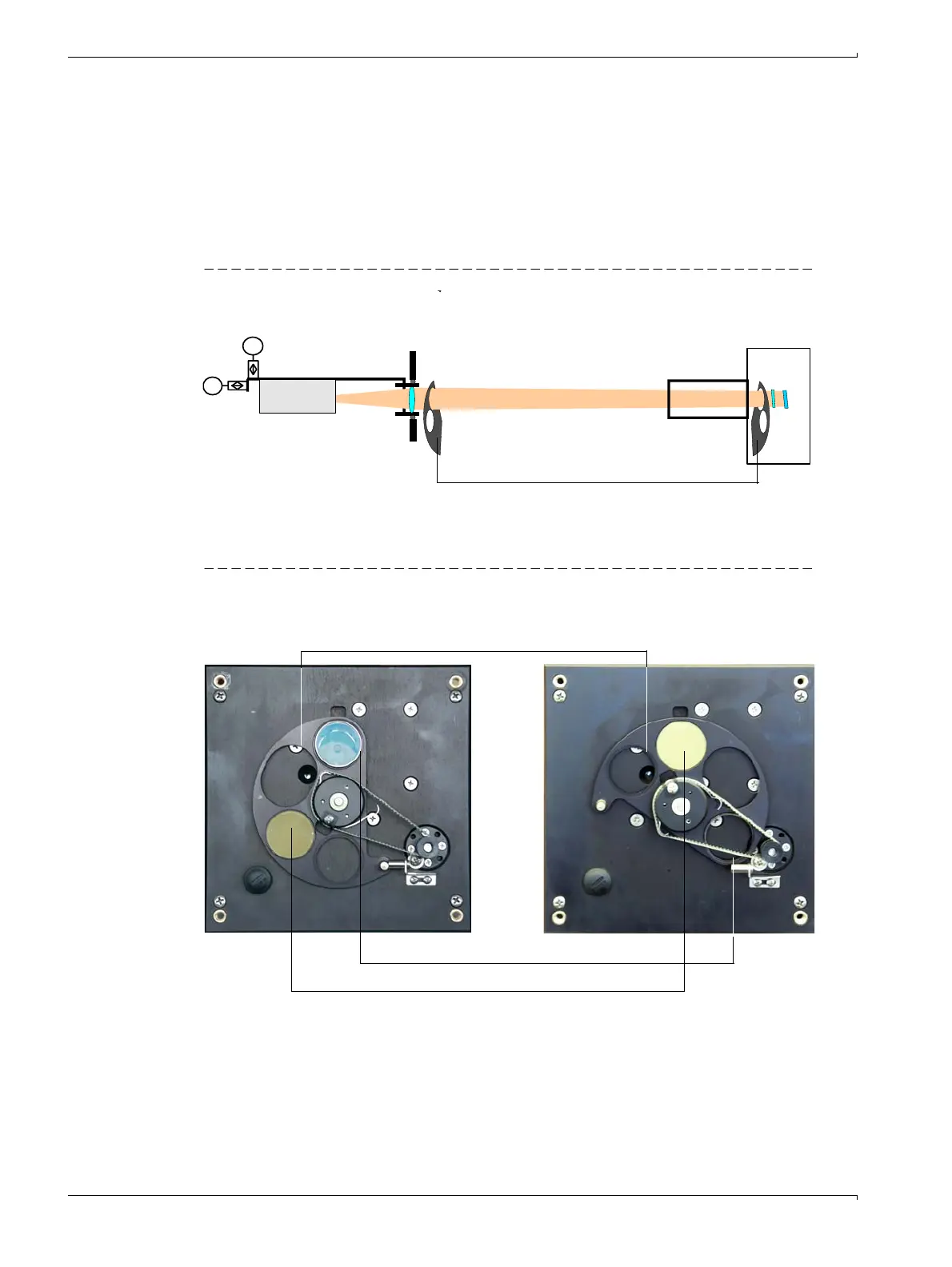

Figure 6 Swivel plate settings on the sender/receiver unit

Sender/receiver unit Reflector

Swivel plate

Measuring position Contamination measurement

Swivel plate

Control reflector (only on the sender side)

Glass pane

Loading...

Loading...