105

8009441/YN36/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

TROUBLESHOOTING AND CLEARING MALFUNCTIONS

9.2 Purge air failure

Failure of the purge air supply demands measures to be taken immediately or within a

short time, depending on the installation conditions, to protect the measuring system. A

purge air failure, however, rarely occurs in practice. It is still however wise to be prepared

for such an occurrence to prevent damage to the measuring system.

Indications of a potential purge air failure

• Error message on systems that are equipped with a pressure difference sensor

• Purge air unit power supply failure

• Increase in the enclosure temperature of the GM35 SR-unit

• Rapid increase in contamination on the optical interface of the SR-unit

• Hose for the purge air supply to the purge air fixture is visibly loose or damaged.

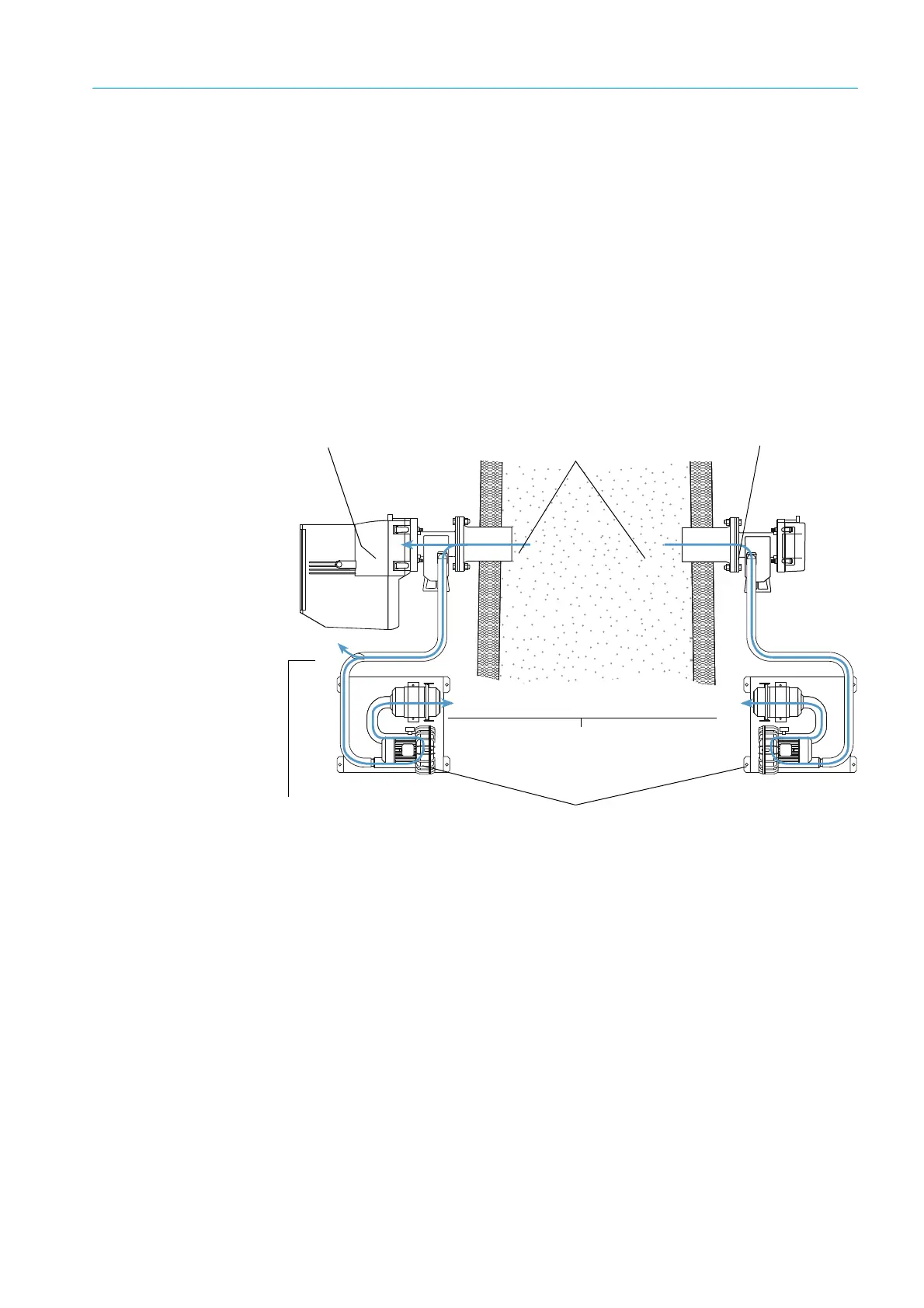

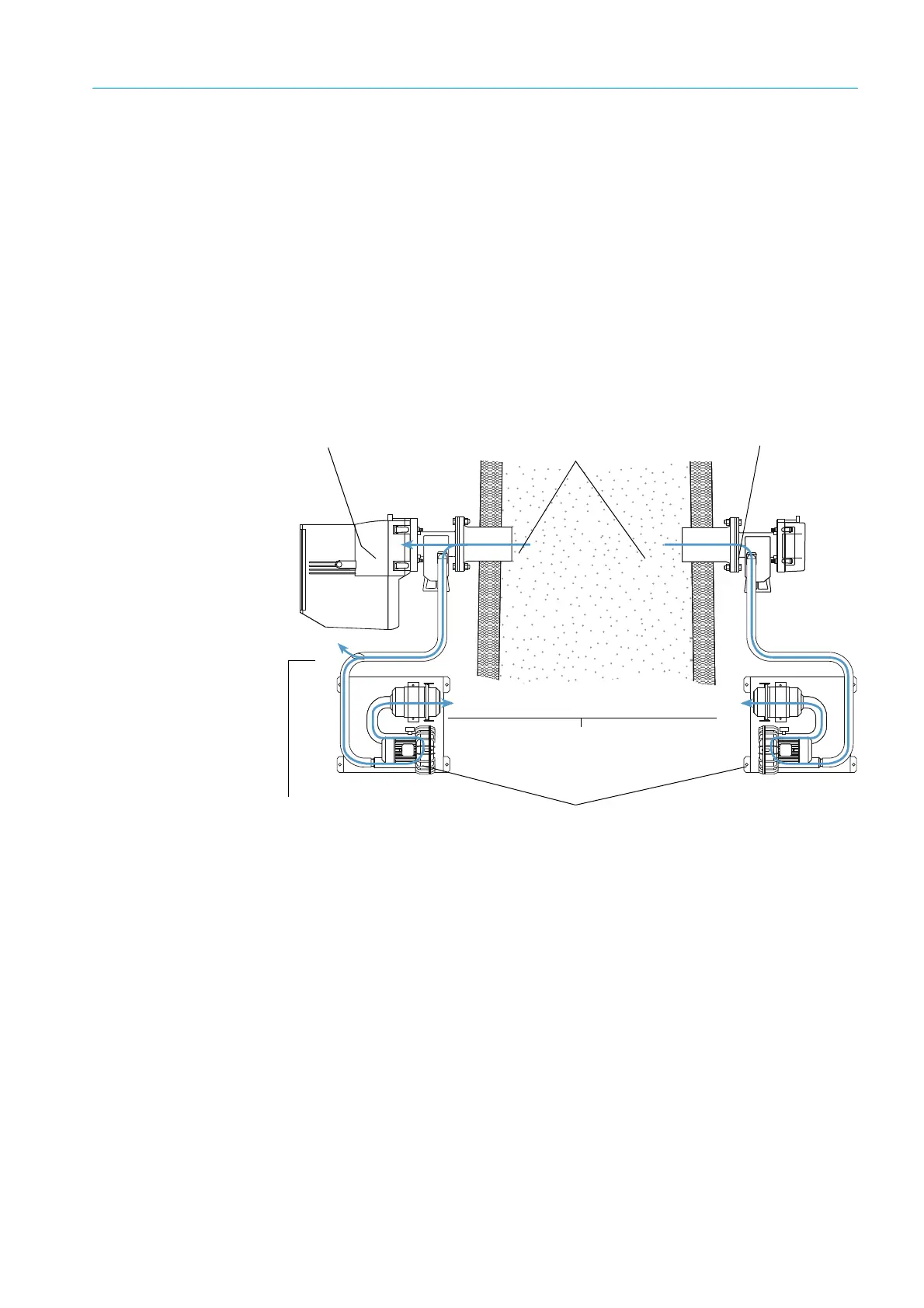

Fig. 75: Possible consequences of a purge air failure

Tools for troubleshooting

• Suitable protective equipment (protective clothing, protective gloves, etc.) that enable

the gas duct to be opened safely and the SR-unit and reflector removed under the given

installation conditions (hot/corrosive/noxious/dusty sample gases, overpressure in the

duct).

• 2 wrenches to remove the SR-unit and reflector and, possibly, other tools required to

restore the power supply.

• Flange cover to seal off the flange opening when the measuring system is removed.

Sample gas penetrating through

the purge air fixtures

Contamination and/or thermal

damage of the reflector

Contamination of the optical

interface, SR-unit overheats

Sample gas escapes if the

purge air supply hose is

damaged or disconnected

Purge air unit possibly overheats or is

damaged by inflowing sample gas.

Sample gas possibly escapes through the

failed purge air unit

Loading...

Loading...