14

8009441/YN36/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

PRODUCT OVERVIEW

2.3 Functional principle

2.3.1 Opto-electronic in-situ measuring principle

The Gas Analyzer GM35 is based on the in-situ technique using opto-electronic direct

measurement. Measured values are recorded through no-contact measurement directly in

the gas flow across the entire duct cross-section (cross-duct). The GM35 SR-unit

determines the concentration of the respective gas component based on wavelength-

specific light absorption by the gas mixture in the active measuring path.

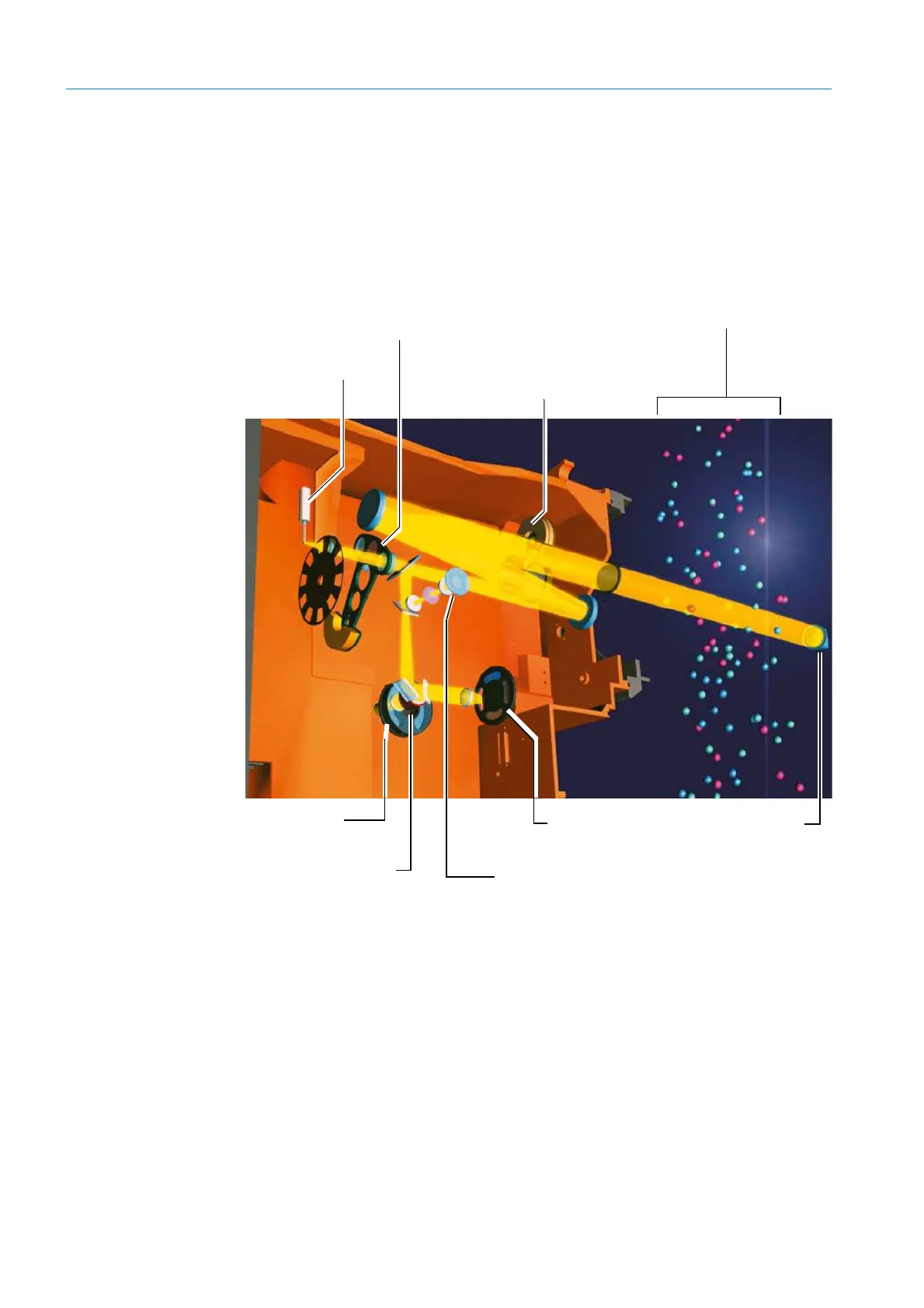

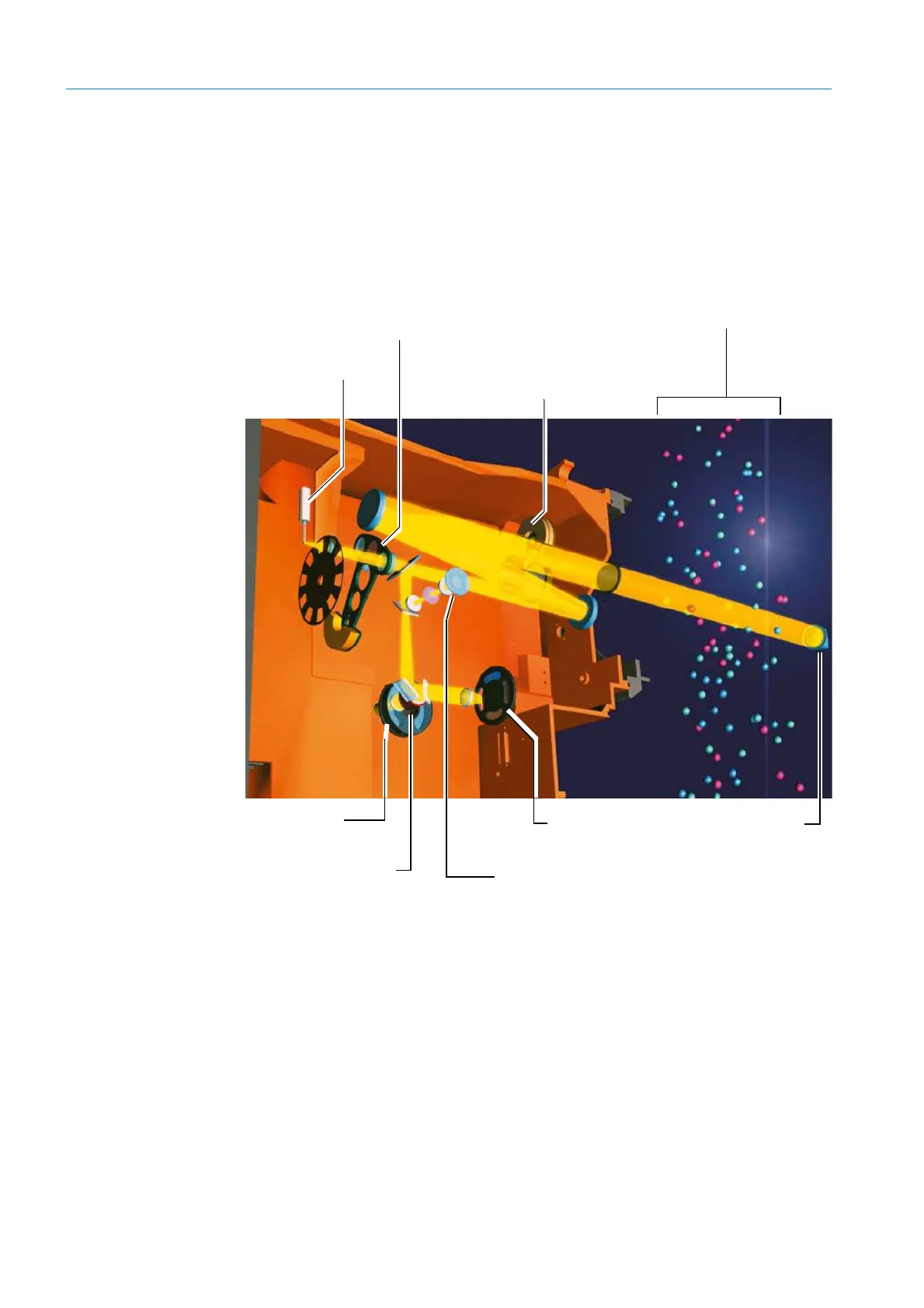

Fig. 3: Optics layout for the GM35

The beam from the sender/receiver unit (SR-unit) passes lengthwise through the active

measuring path (see

see “Fitting recommendation for the mounting flange (duct diameter

not representative)”, page 20) and is reflected by the reflector at the other end. The

reflected light from the beam splitter then passes through a filter or cell wheel to detectors

configured optionally to measure CO, N

2

O as well as CO

2

and H

2

O. By filtering the light

received into its spectral components, the receiver elements record the absorption of the

gas molecules at characteristic points of the spectrum in the IR range of 1.6 to 4.9 µm.

Cross-sensitivities with gases other than those to be measured are avoided by selecting

these evaluation ranges within the IR spectrum in conjunction with the evaluation algo-

rithms used (see

“Signal evaluation”, page 15).

CO or

N

2

O detector

Measuring path in gas duct

Cell wheel and detector

for CO- or N

2

O measurement

IR transmitter

lamp

Zero point reflector

and blanking diaphragm

Filter Fwheel and detector

for CO

2

and H

2

O

Reflector

Reference filter for pivoted

segment

Visor with opto-electronic adjustment tool

Filter wheel and detector

or CO

2

and H

2

O

Loading...

Loading...