114

8009441/YN36/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

TECHNICAL DATA, CONSUMABLES AND SPARE PARTS

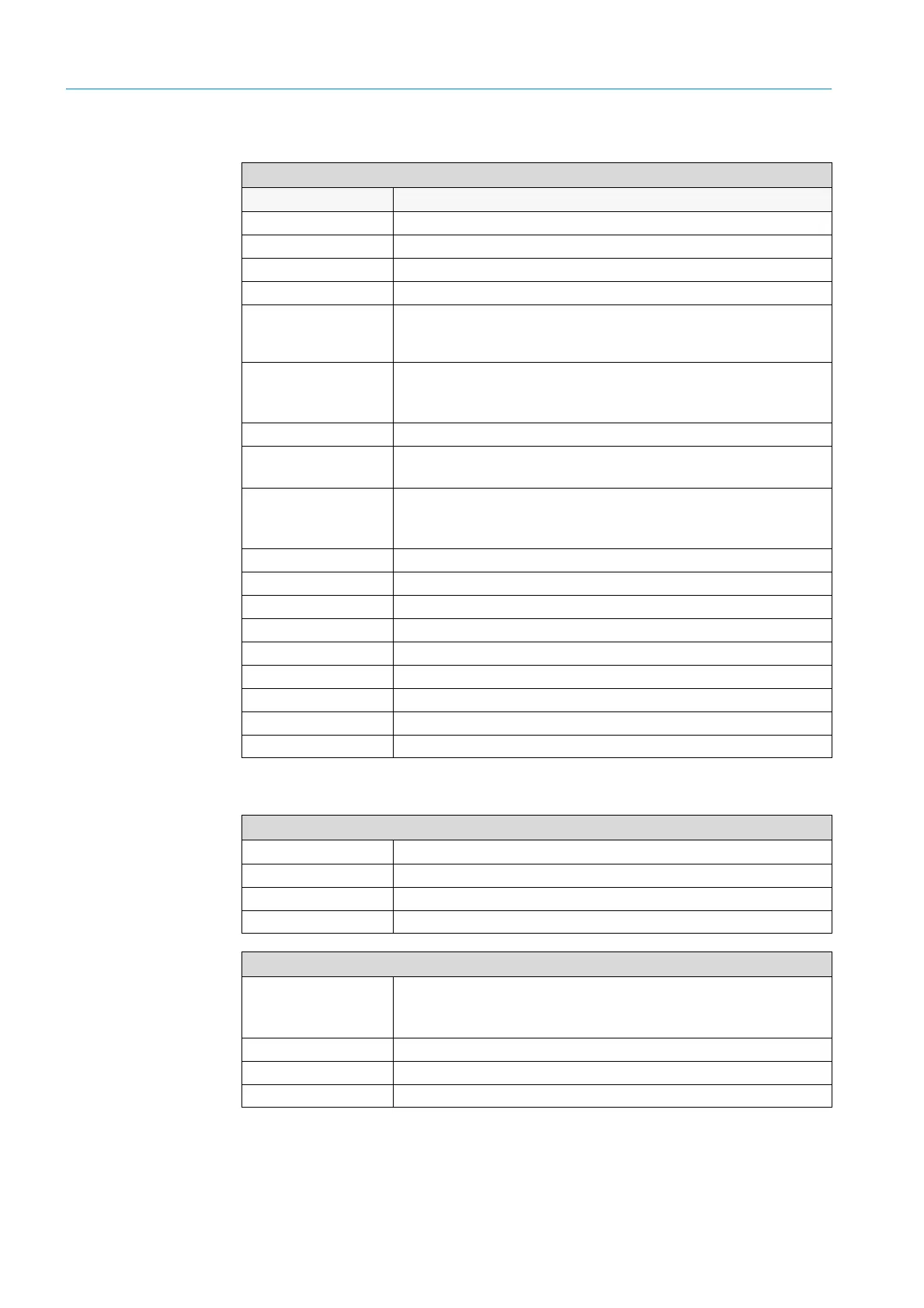

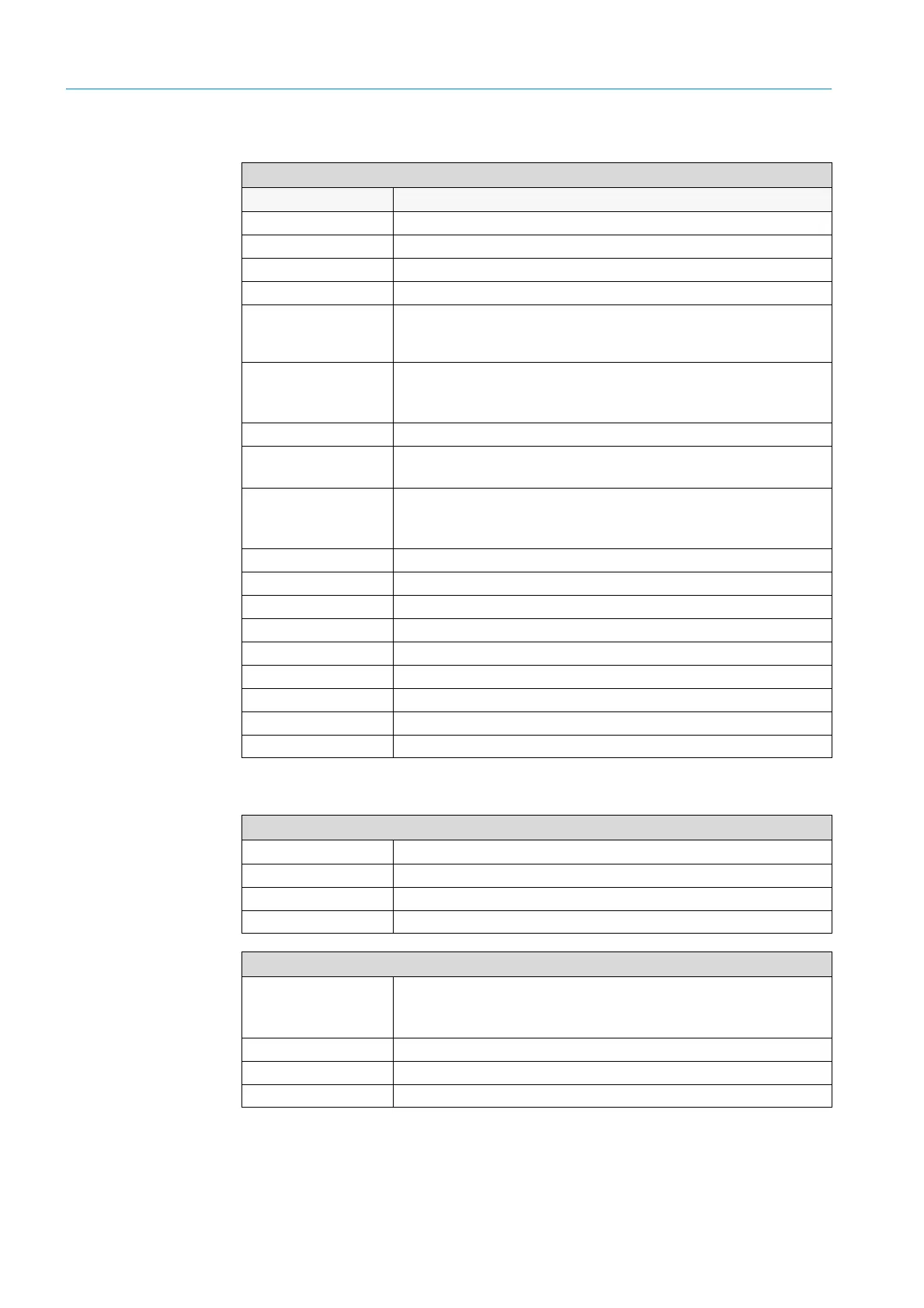

10.1.1 GM35 system component

GM35 Sender/receiver unit

Measuring principle In-situ, IR filter or gas correlation

Light source IR source

Detectors PbS and PbSe

Response time (t

90

) ≥ 5s

Averaging Can be parameterized as floating integral over 5 to 300 seconds

Interfaces CAN bus (electrically isolated) for transferring data within the GM35

measuring system

RS232 (Service interface)

Indicators • Status LED (operation: green, maintenance: yellow, malfunction/

failure: red)

• Displays the optical alignment

Protection class IP 65 / NEMA 4x

Sample gas tempera-

ture

• 430 °C max.

• N

2

O: 180 °C max.

Ambient temperature • –20 to +55 °C; other temperatures on request

(tested for suitability according to minimum requirement

–20 … 50 °C)–40 °C during continuous operation

Temperature change Max. 10 °C/h

Ambient humidity Max. 96 % rF

Humidity condensation Humidity condensation on optical interfaces not allowed

Shock and vibration As defined in EN 61010-1

Storage temperature –30 to +55 °C

Power supply 115/230 V AC ±10%, 48–62 Hz

Power input 350 VA max.

Dimensions (WxHxD) 291 x 530 x 570 mm

Weight 29 kg

Table 6:

GM35 Reflector unit

Reflector material Gold-coated hollow triple

Protection class IP 65 / NEMA 4x

Dimensions (L x

∅) 140 x 133 mm

Weight 1.5 kg

GM35 Purge air fixtures

Integrated sensors • Flow monitor to monitor purge air feed

• Temperature sensor (purge air)

• Pressure sensor

Data transfer CAN bus (electrically isolated)

Dimensions (L x ∅) 220 x 240 mm

Weight 7 kg

Loading...

Loading...