109

8009441/YN36/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

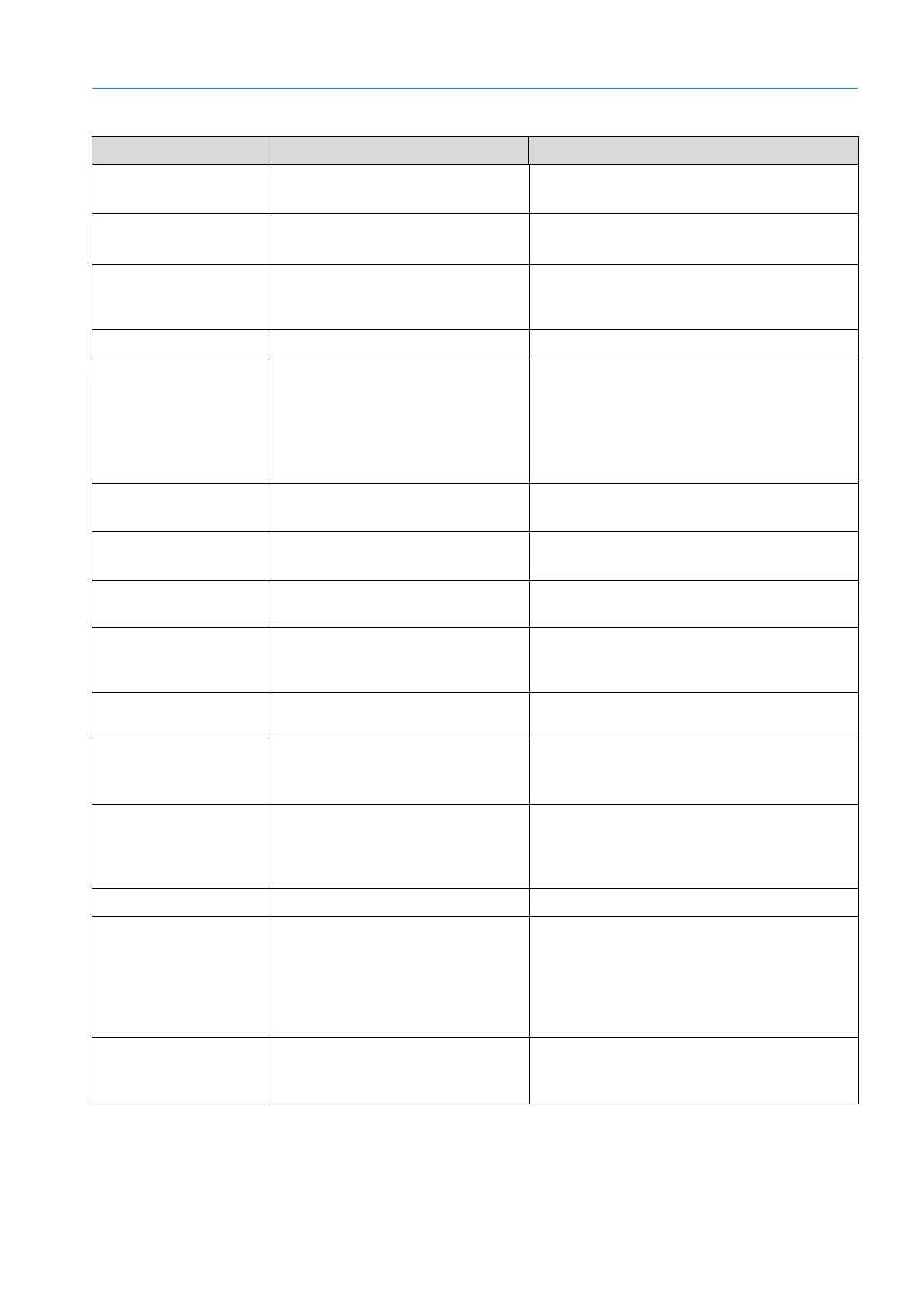

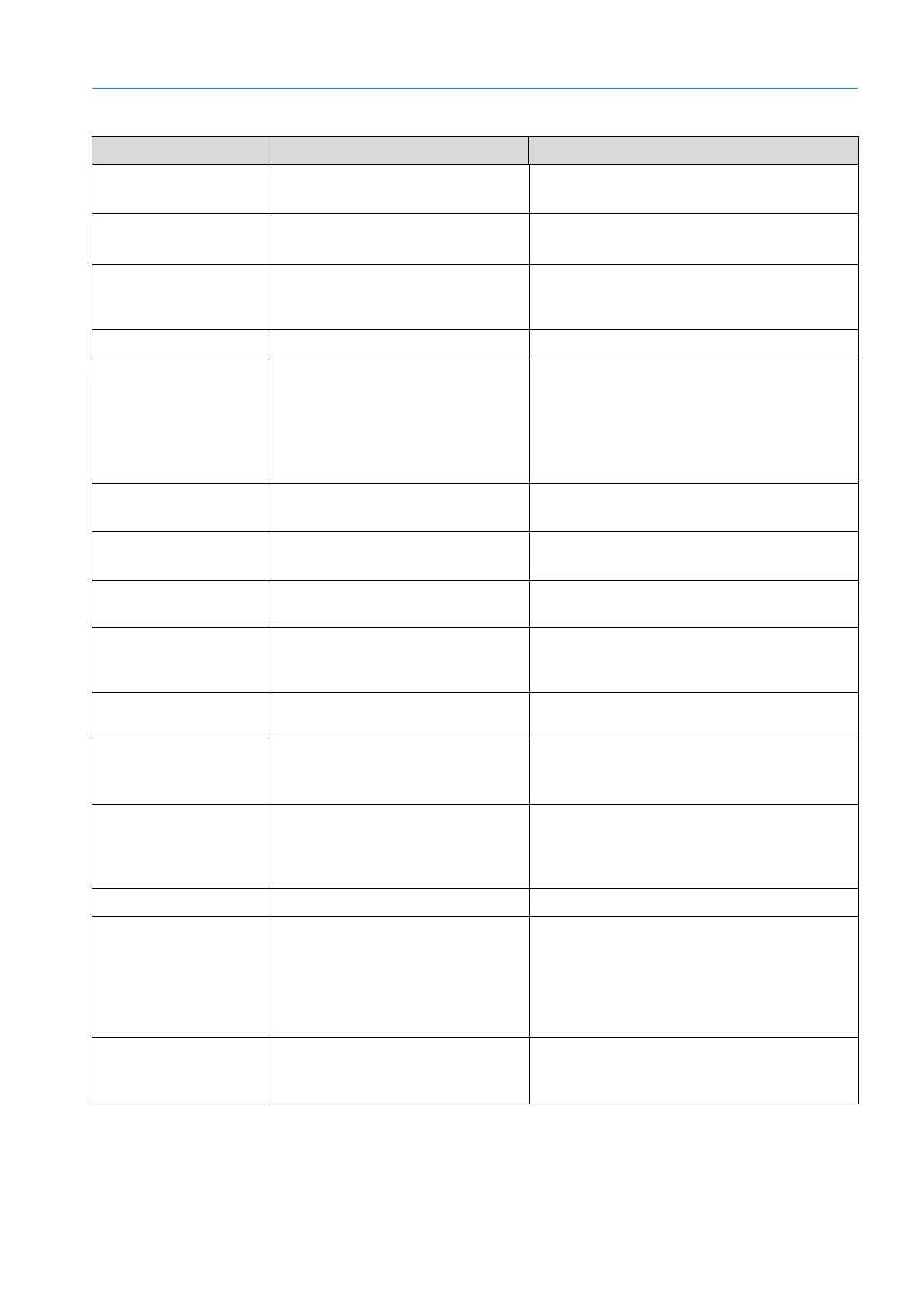

TROUBLESHOOTING AND CLEARING MALFUNCTIONS

H2O CUVETTE com. No connection between CO

2

/H

2

O

module and motor of cell

▸ Contact Service.

H2O div. Zero CO

2

/H

2

O module adjustment data

invalid

▸ Carry out zero adjust, see page 80.

▸ Contact Service.

H2O EEPROM Invalid parameter set for CO

2

/H

2

O

module

▸ Carry out zero adjust on GM35;

see page 79.

▸ Contact Service.

H2O Motor fault Motor fault on CO

2

/H

2

O filter wheel ▸ Contact Service.

H2O No signal • H

2

O signals too low; measurement

not possible

• Dust content too high

• H

2

O detector or IR source defective

CO (N

2

O) measuring duct continues to

run

▸ Check contamination; clean optical interfaces

(

see page 90f).

▸ Check optical alignment,

page 92.

▸ Exchange IR source or measurement module,

or contact Service.

H2O Sig. High CO

2

/H

2

O measurement signal

distorted

▸ Readjustment necessary,

see page 80.

▸ Contact Service if necessary.

H2O temp. detec. CO

2

/H

2

O detector temperature

outside tolerance

▸ Contact Service.

Mirror adj. End Automatic beam tracking at end stop,

further tracking not possible

▸ Check alignment; see page 92.

▸ Contact Service.

Mirror com. No communication with automatic

beam tracking; measurement

continues to run

▸ Contact Service.

Sensor communication No connection between EvU and

GM35

▸ Check CAN connection, repair if necessary.

VISOR com. No connection between CO

2

/H

2

O

module and visor unit

▸ Check cable connection is secure with correct

seat; repair if necessary.

▸ If the error cannot be cleared: Contact Service.

VISOR fault Visor unit data invalid or signals

distorted

▸ Check alignment;

see page 92.

▸ If no display seen in visor during alignment or

if message remains despite correct alignment,

contact Service.

VISOR init. Visor default setting invalid

▸ Contact Service.

VISOR No signal • Visor signals too low

• Dust content too high

• IR source defective

Measurement continues to run

▸ Check contamination; clean optical interfaces

(

see page 90f).

▸ Check optical alignment,

page 92.

▸ Exchange IR source or contact Service

▸ Carry out zero adjust after replacement,

page 80.

Zero com. No connection between CO

2

/H

2

O

module and motor of zero point reflec-

tor

▸ Check cable connection is secure with correct

seat; repair if necessary.

▸ If the error cannot be cleared: Contact Service.

Error message Component/possible causes Clearance

Loading...

Loading...