• The diameters and end faces of the adapter for supporting the encoder cover or the static

part of the rotating union should be turned in one clamping if possible. For simpler

machining, the adapter can be axially split. It is important that the nish-machining of the

support diameter and end faces is performed in the assembled condition and in one

clamping.

Mounting on water-cooled motors

Water-cooled motors have a “2” in the 11th position of Article No. together with option Y64.

Use rotating unions with radial or axial connections.

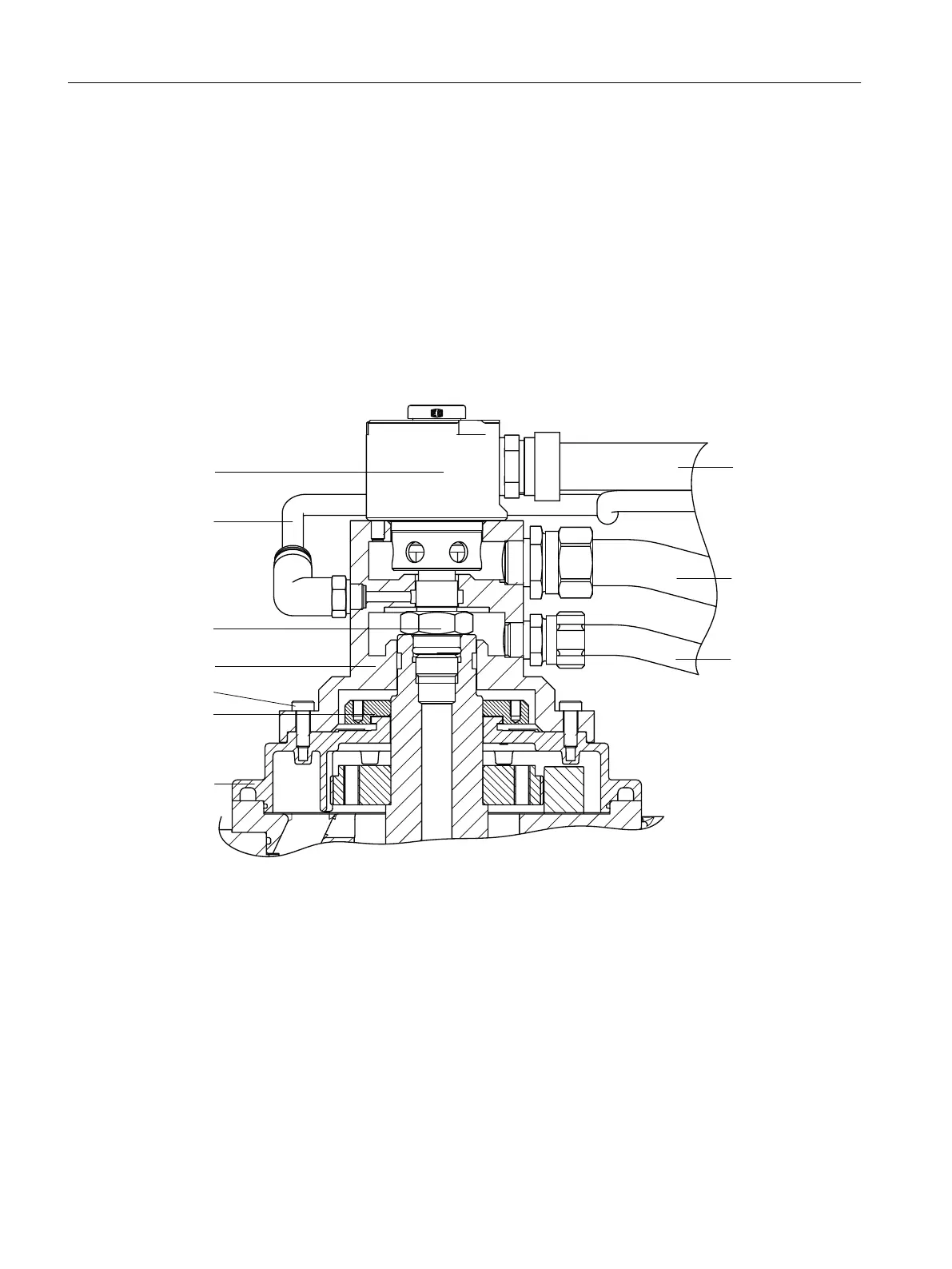

Mounting a bearingless rotating union on a water-cooled motor

1 Encoder cover

2 Balancing disk

3 Adapter

4 6 x M5 bolts

5 Rotating part of the rotating union, e.g. DEUBLIN 1129-050-301

6 Static part of the rotating union, e.g. DEUBLIN 1129-050-301

7 Leakage hose (min. internal diam. 12mm)

8 Leakage hose as backup and for faults

9 Inlet hose

10 Sealing air connection

Mechanical properties

4.6Mounting of rotating unions on 1PH8 hollow-shaft motors

1PH8 SIMOTICS M main motors

104 Conguration Manual, 12/2022, A5E51895839A

Loading...

Loading...