When the motor is mounted onto a machine, a new system, which is capable of vibration, is

created with modied natural frequencies. These can lie within the motor speed range.

This can result in undesirable vibrations in the mechanical drive transmission.

Note

Avoiding natural frequencies when mounting

Motors must be carefully mounted on adequately sti foundations or bedplates. Additional

elasticities of the foundation/bedplates can result in resonance eects of the natural frequency

at the operating speed and therefore result in inadmissibly high vibration values.

The magnitude of the natural frequency when the motor is mounted depends on various

factors and can be inuenced by the following points:

• Mechanical transmission elements (gearboxes, belts, couplings, pinions, etc.)

• Stiness of the machine design to which the motor is mounted

• Stiness of the motor in the area around the foot or customer ange

• Motor weight

• Machine weight and the weight of the mechanical system in the vicinity of the motor

• Damping properties of the motor and the driven machine

• Mounting type, mounting position (IM B5, IM B3, IM B35, IM V1, etc.)

• Motor weight distribution, i.e. length, shaft height

4.10.3 Misalignment

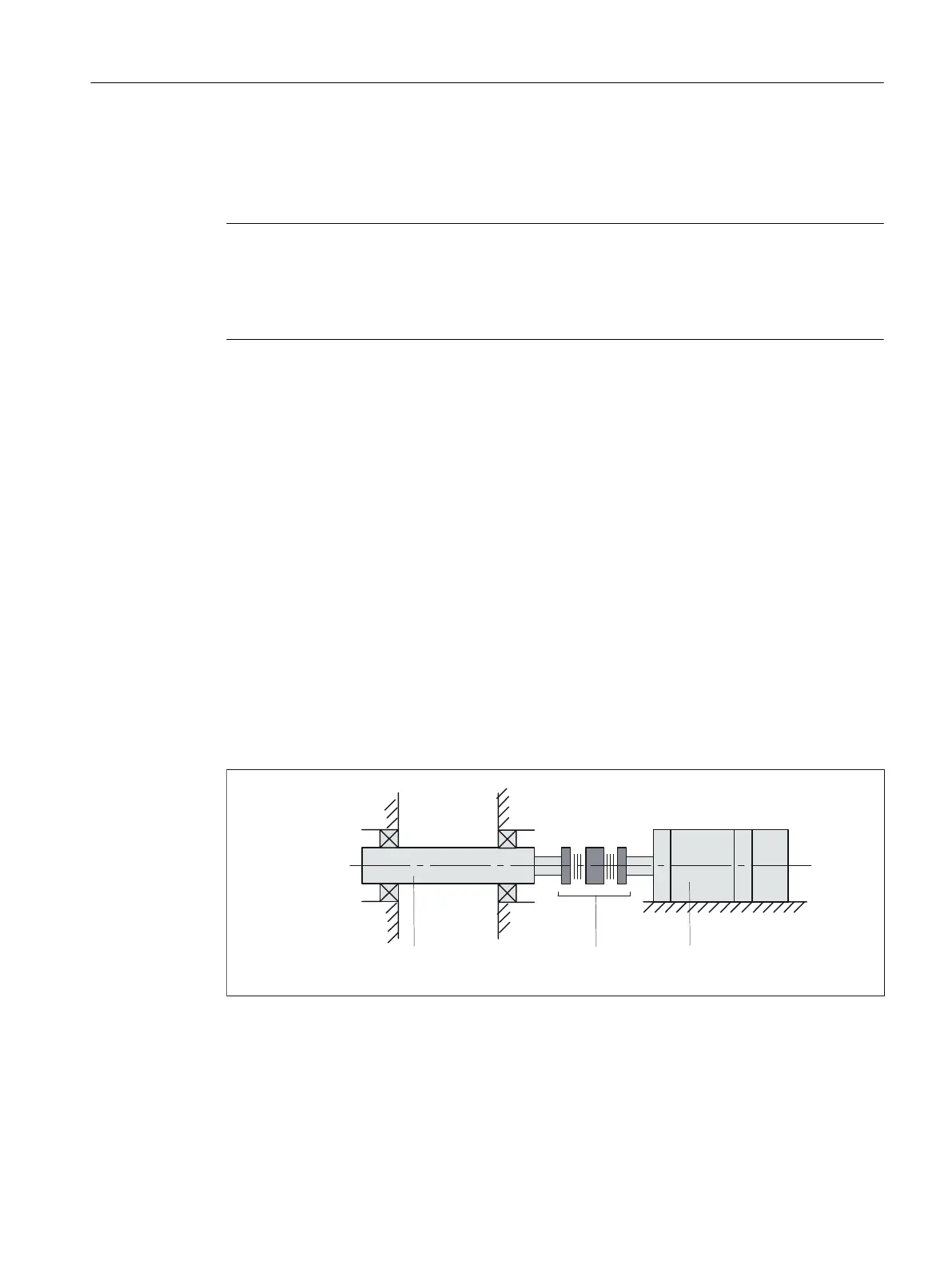

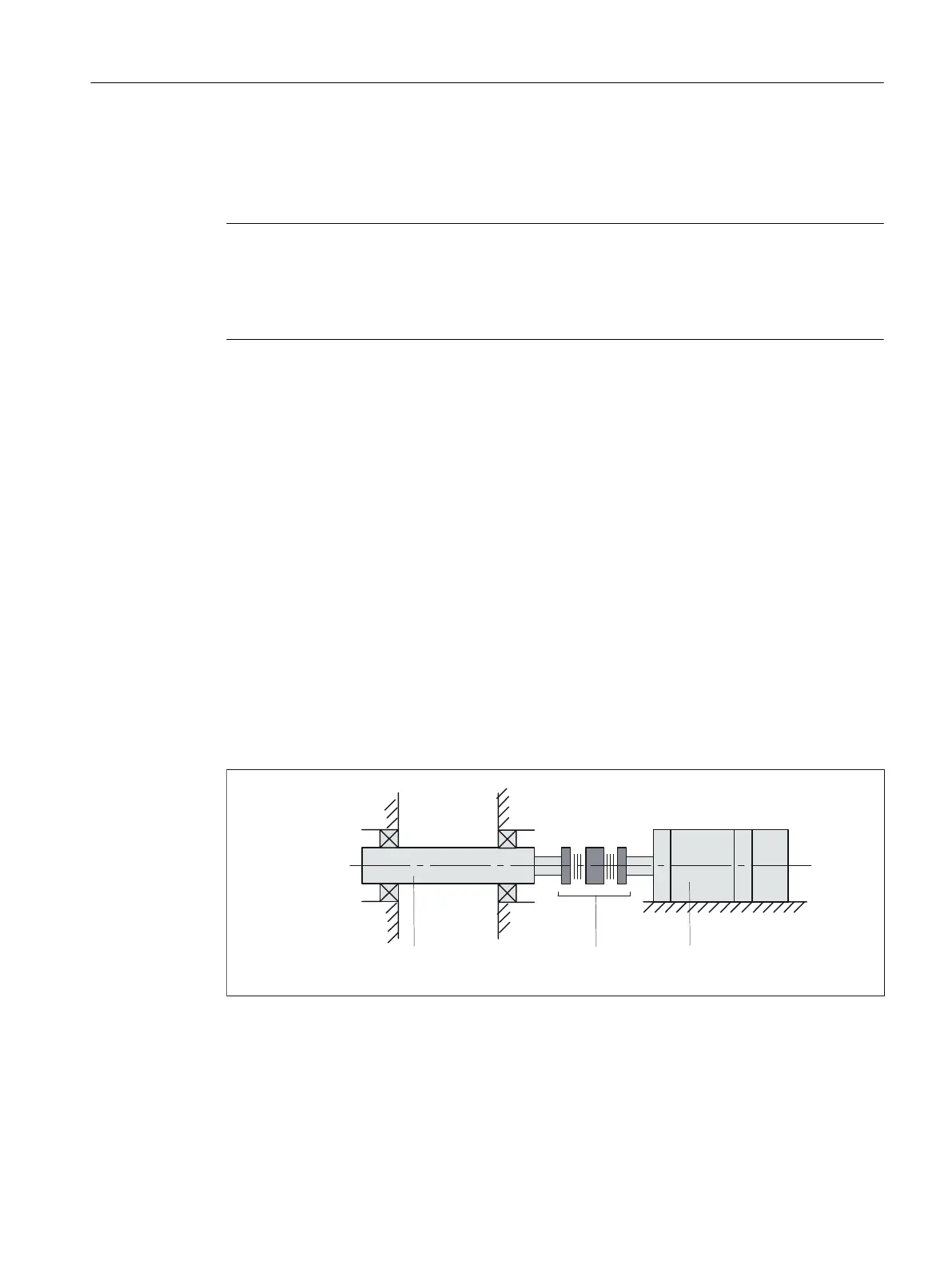

To avoid or minimize misalignment, a compensating coupling should be used (see the diagram).

'ULYHRXWWUDQVPLVVLRQ

VKDIWZLWKRZQEHDULQJV

&RXSOLQJ0RWRU

Figure4-64 Mechanical output transmission shaft with its own bearings and compensating coupling

If possible, the motor should not be directly and rigidly coupled to an output transmission

shaft which has its own bearings.

Mechanical properties

4.10Vibration response

1PH8 SIMOTICS M main motors

Conguration Manual, 12/2022, A5E51895839A 149

Loading...

Loading...