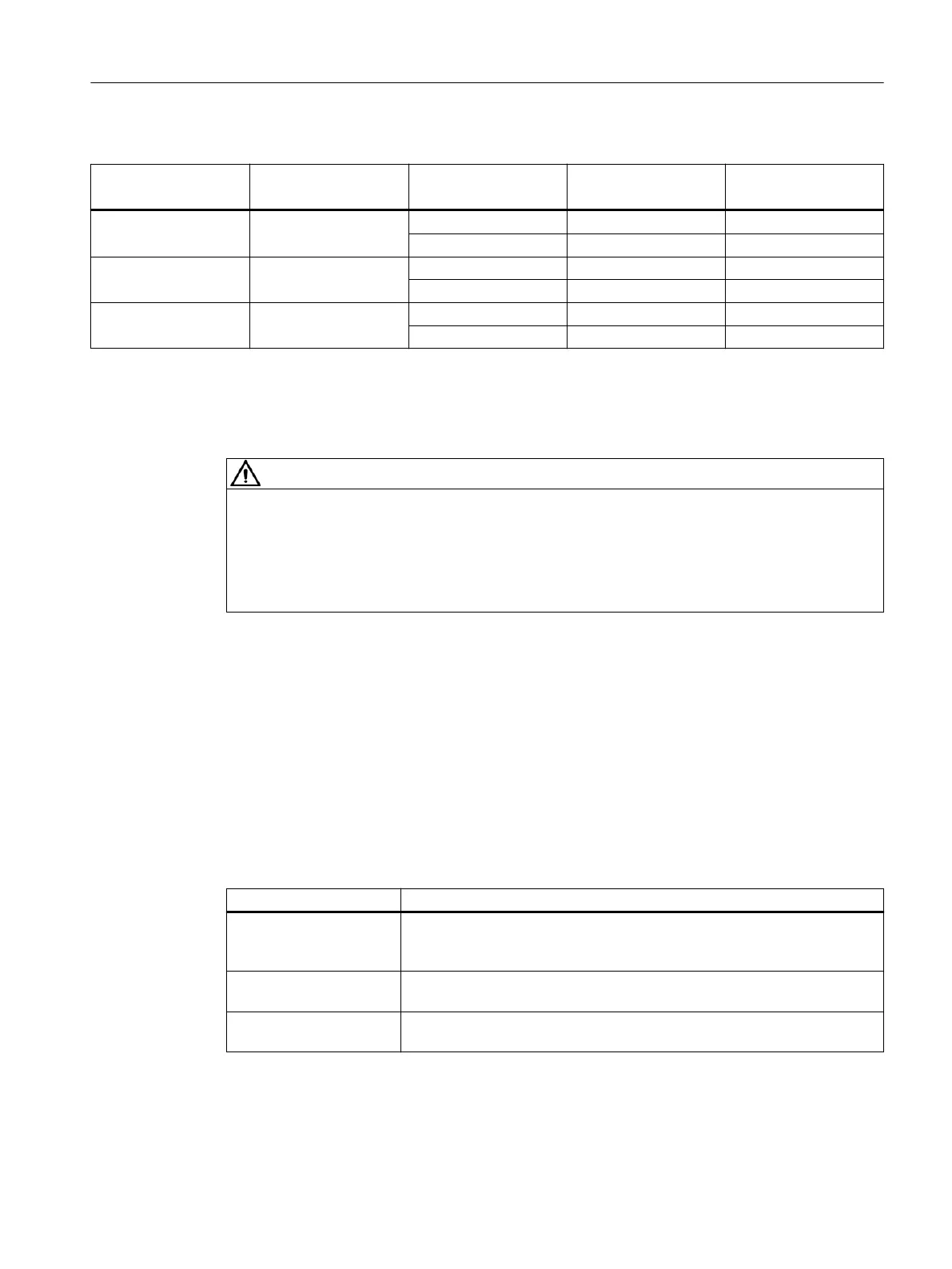

Table 4-6 Diameter, minimum air ow and pressure drop

Shaft height

mm

Diameter

mm

Degree of protection Minimum air quantity

m

3

/s

Pressure drop

Pa

180 300 IP23 0.21 450

IP55 0.17 550

225 350 IP23 0.33 600

IP55 0.31 650

280 Adapter required IP23 0.52 600

IP55 0.42 600

4.1.3 Water cooling

WARNING

Defective work on the cooling circuit

Defective work on the cooling circuit can cause injury and/or damage to property.

• Only qualied personnel may assemble, install, and commission the cooling circuit.

• Perform installation or service work on the cooling circuit only when the system is de-

energized.

The electrochemical processes that take place in a cooling system must be minimized by

choosing the right materials. For this reason, mixed installations, i.e. a combination of dierent

materials, such as copper, brass, iron, or halogenated plastic (PVC hoses and seals), should not

be used or should be limited to the absolutely essential minimum.

There are 3 types of cooling circuits:

• Closed cooling circuit

• Semi-open cooling circuit

• Open cooling circuit

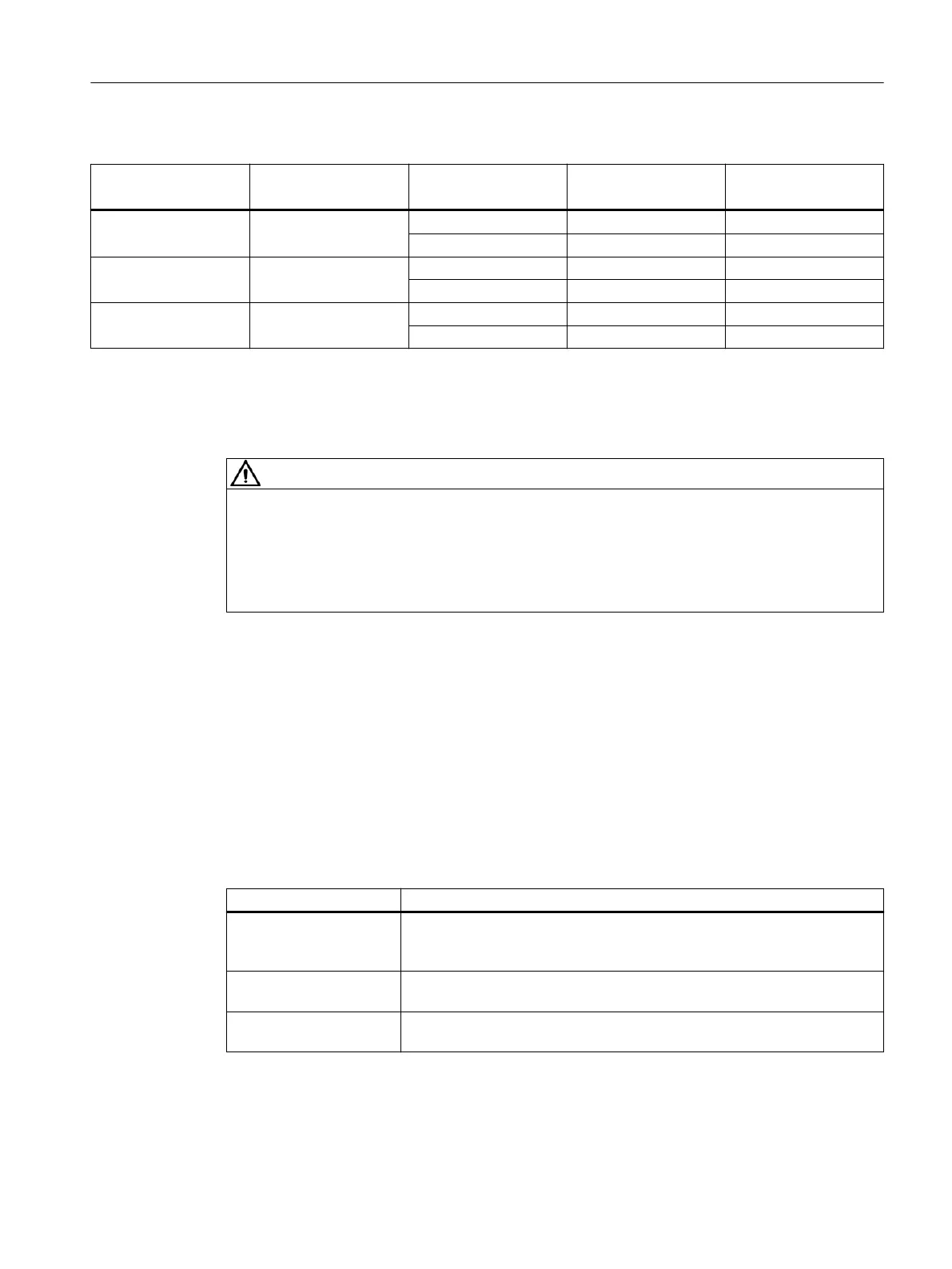

Table 4-7 Description of the various cooling circuits

Denition Description

Closed cooling circuit The pressure equalizing vessel is closed (oxygen cannot enter the system)

and has a pressure relief valve. The coolant is only routed in the motors and

converters as well as the components required to dissipate heat.

Semi-open cooling circuit Oxygen can only enter the cooling system through the pressure equalization

vessel, otherwise the same as "closed cooling circuit."

Open cooling circuit (tow‐

er system)

The coolant is cooled in a tower. In this case, there is intensive oxygen con‐

tact.

Mechanical properties

4.1Cooling

1PH8 SIMOTICS M main motors

Conguration Manual, 12/2022, A5E51895839A 71

Loading...

Loading...