• Unused cable entries must be closed and the screw plugs must be screwed tight.

• All the sealing surfaces must be in a perfect condition.

Connecting the ground conductor

The ground conductor cross-section must be in full conformance with the installation

regulations, e.g. acc. to IEC/EN 60204-1.

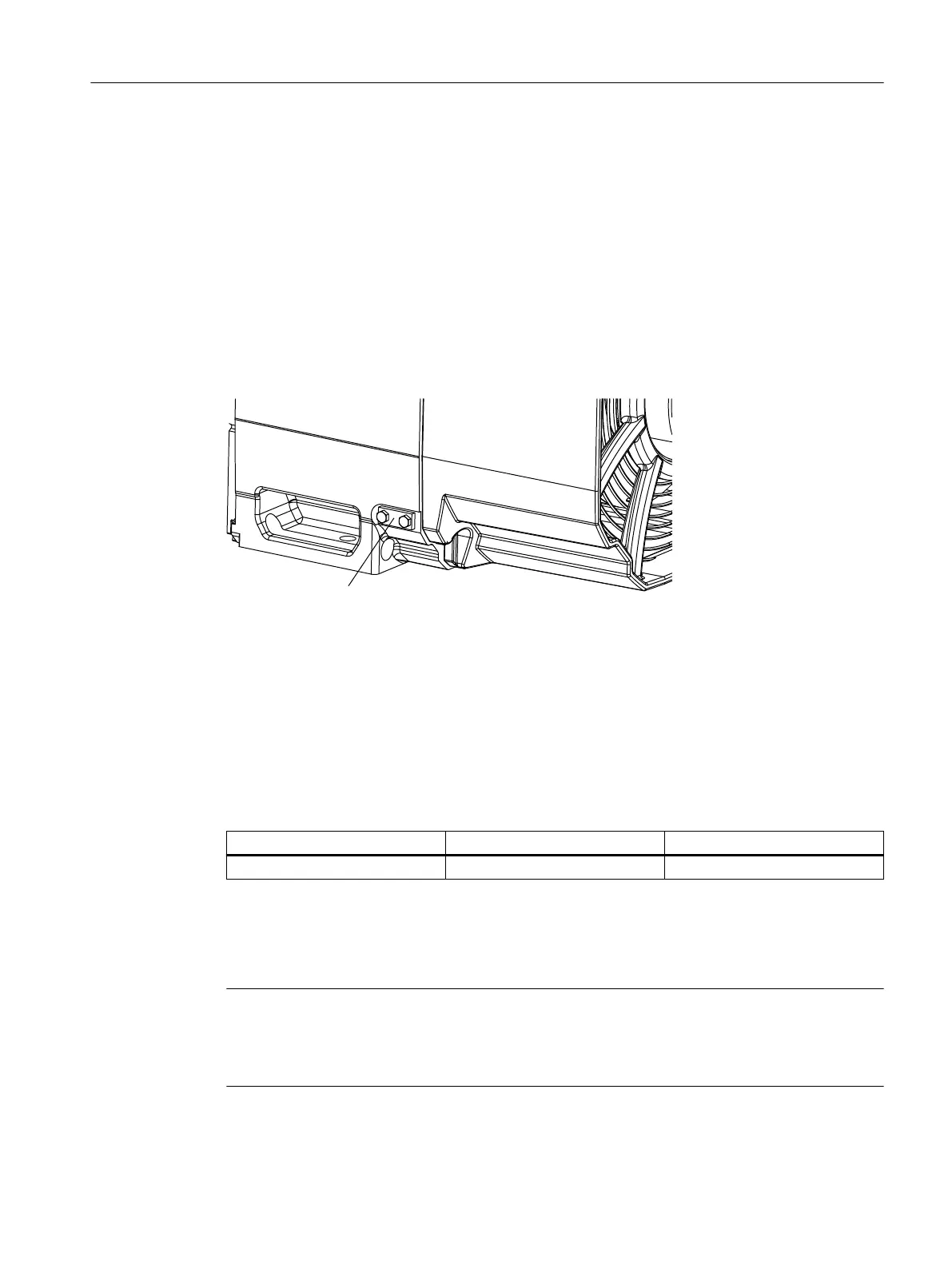

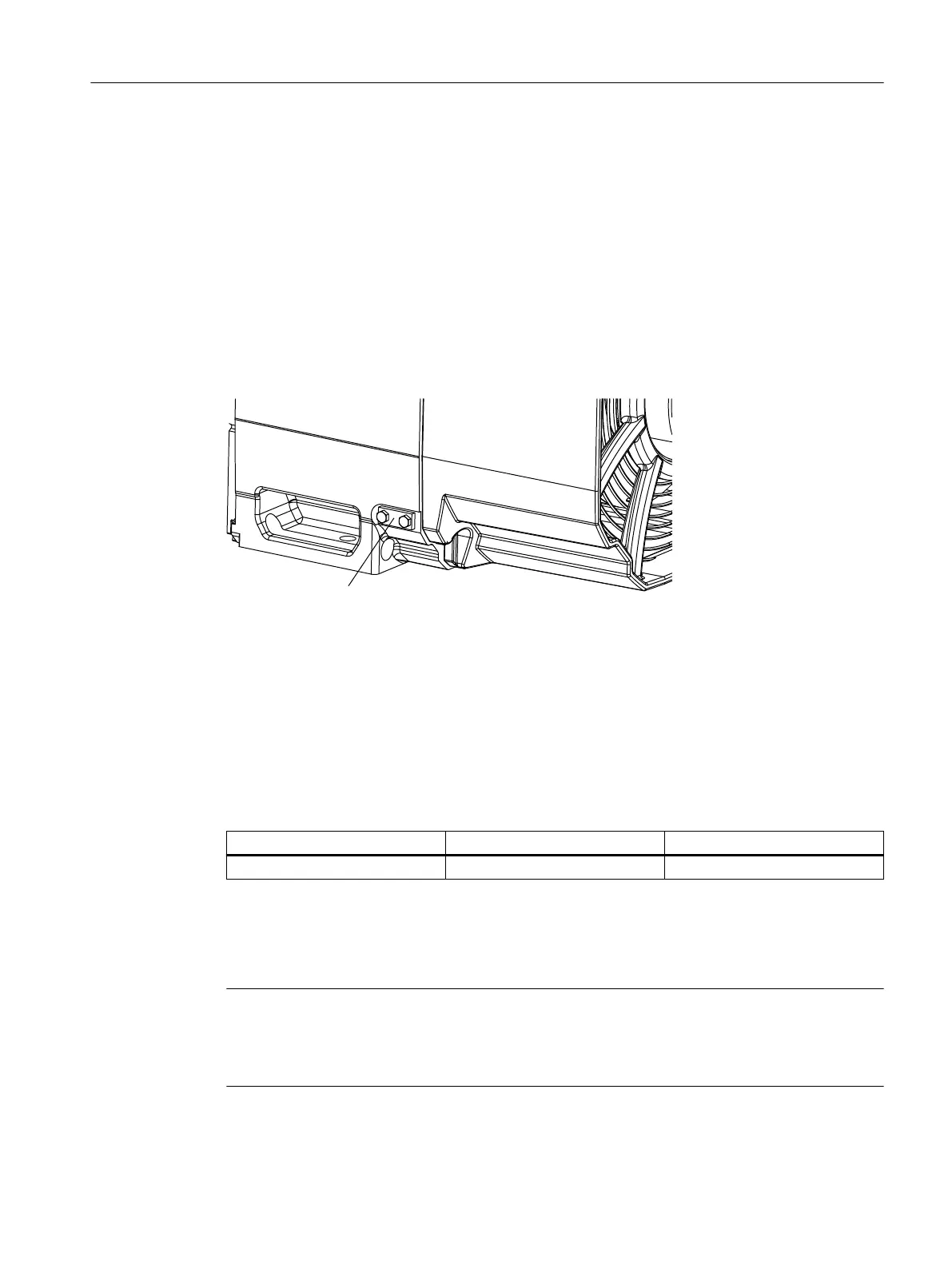

For shaft height 225 and shaft height 280, also connect the grounding conductor to the

motor end shield. There is a clamping lug ① for the ground conductor at the designated

connection point. This is suitable for connecting multi-conductor cables with cable lugs or

ribbon cables with the appropriate conductor terminations.

Figure9-2 Terminal lug for grounding conductor (shaft heights 225 and 280)

When connecting up, ensure that

• the connecting surface is bare and is protected against corrosion using a suitable substance,

e.g. acid-free Vaseline

• the at and spring washers are located under the screw head

• the minimum necessary screw-in depth and the tightening torque for the clamping screw

must be maintained

Table 9-1 Screw-in depth and tightening torque

Screw Penetration depth: Tightening torque

M8 x 30 >8mm 20Nm

9.3.3 Routing cables in a damp environment

Note

Routing cables in humid/moist environments

If the motor is mounted in a humid environment, the power and signal cables must be routed

as shown in the following gure.

Electrical connection

9.3System integration

1PH8 SIMOTICS M main motors

Conguration Manual, 12/2022, A5E51895839A 227

Loading...

Loading...