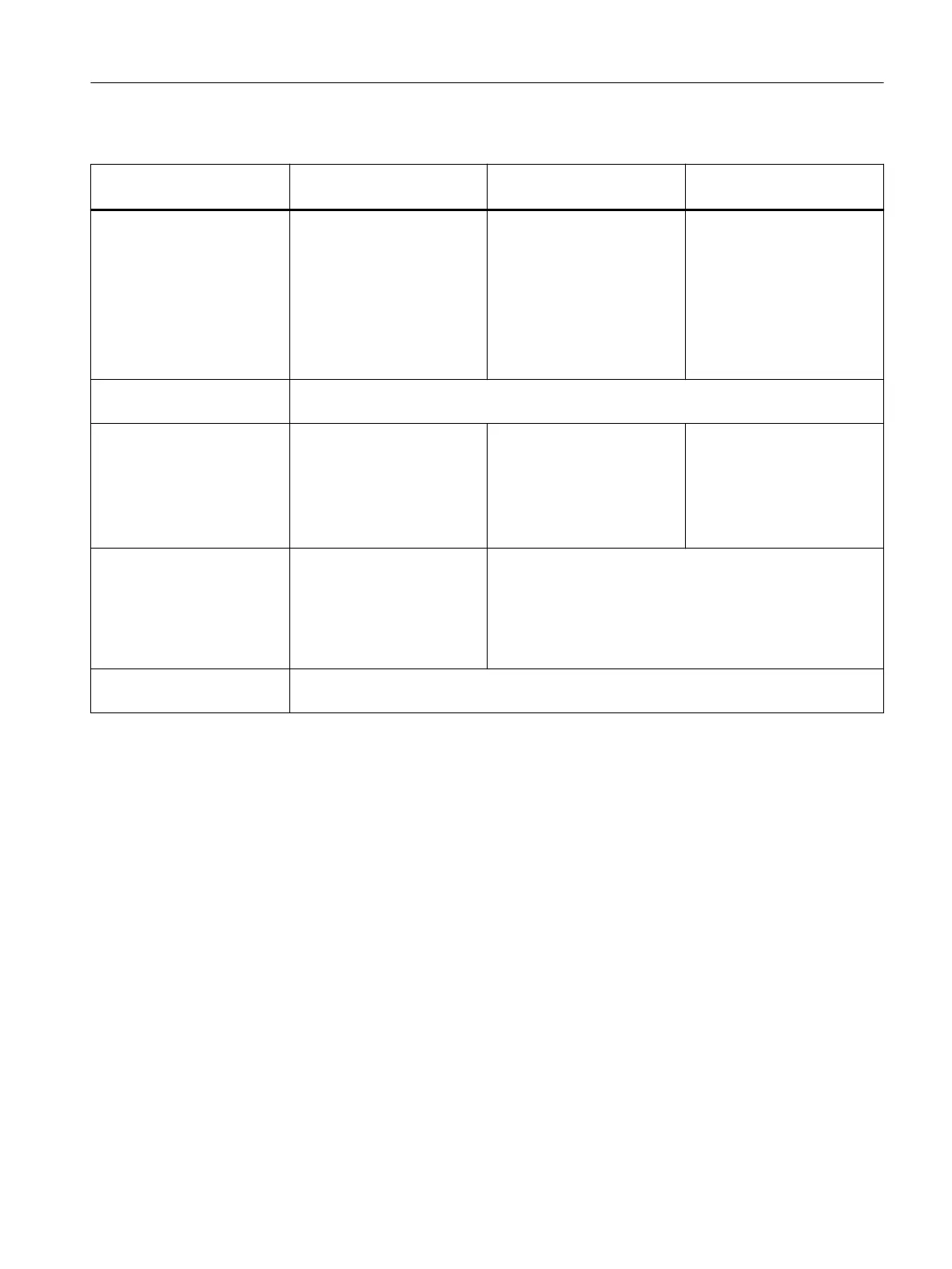

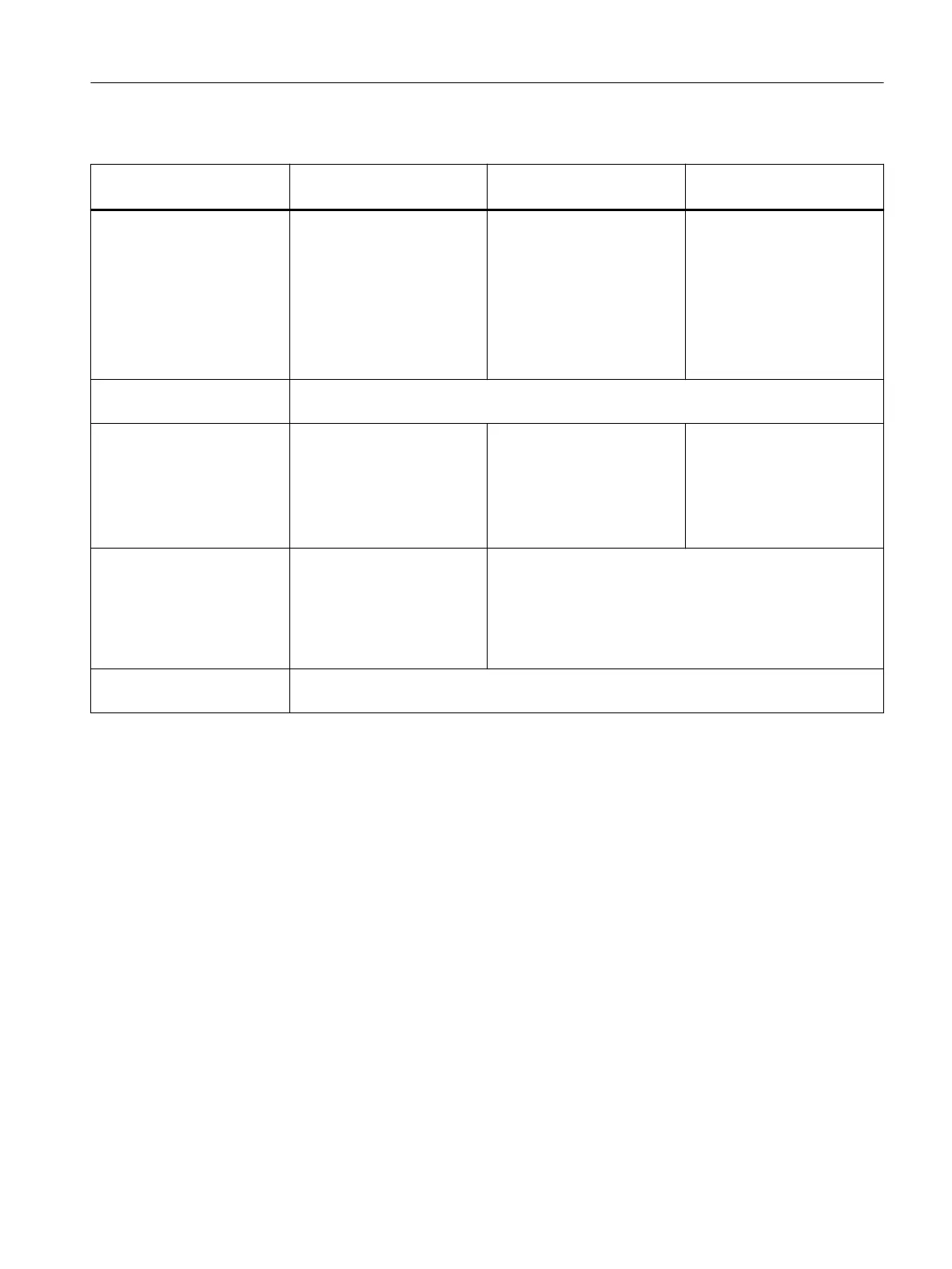

Table 4-30 Requirements placed on the balancing process as a function of the motor balancing type

Balancing equipment/

Process step

Motor

Half key balanced

Motor balanced with full key Motor with plain

shaft end

Auxiliary shaft to balance

the mounted component

• Auxiliary shaft with key‐

way

• Keyway with the same di‐

mensions as in the motor

shaft end

• Auxiliary shaft half key

balanced

• Auxiliary shaft with key‐

way

• Slot design with the ex‐

ception of the slot width

(as the motor) can be free‐

ly selected

• Auxiliary shaft full key bal‐

anced

• Auxiliary shaft without

keyway

• If required, use a tapered

auxiliary shaft

• Balance quality of the auxiliary shaft ≤ 10 % of the required balance quality of the compo‐

nent to be mounted to the motor

Attaching the mounted com‐

ponent

to the auxiliary shaft for bal‐

ancing

• Attached using a key

• Key design, dimensions

and materials the same as

at the motor shaft end

• Attached using a key

• Key design, dimensions

and material the same as

used for the full key bal‐

ancing of the auxiliary

shaft

• Attach the component as

far as possible without

any play,

e.g. using a light press t

on the tapered shaft

Position the mounted compo‐

nent on the auxiliary shaft

• Select a position between

the mounted component

and the key of the auxili‐

ary shaft so that it is the

same when mounted on

the actual motor

• No special requirements

Balance the mounted compo‐

nent

• Two-plane balancing is recommended - i.e. balancing in two planes at both sides of the

mounted components at right angles to the axis of rotation

Special requirements

If special requirements are placed on the smooth running operation of the machine, we

recommend that the motor together with the output components is completely balanced. In this

case, balancing should be carried out in two planes of the output component.

4.9.2 Balancing 1PH8 motors with "Premium Performance" bearing version

The on-site mechanical system vibration characteristics depend on factors such as the output

elements, mounting situation, alignment, installation, and external vibration and can increase

the level of motor vibration. Under certain circumstances, the rotor may have to be balanced

completely with the output element.

1PH8 motors are supplied with "special" vibration severity. Mounting a coupling element on

the shaft extension changes the rotor balancing state. As a consequence, after mounting

coupling elements, the rotor must be completely balanced. The following description shows,

using an example, the procedure for 1PH8 motors with "Premium Performance" bearing

version. You must determine the vibration severity and the position of the imbalance by

making the appropriate measurements. You can then remove the imbalance.

Mechanical properties

4.9Balancing

1PH8 SIMOTICS M main motors

Conguration Manual, 12/2022, A5E51895839A 141

Loading...

Loading...