NOTICE

Destruction of the motor for a thermally critical load

There is no adequate protection during a thermally critical load, e.g. a high overload at motor

standstill.

• Take additional protective measures, e.g. an overcurrent relay.

• The "thermal motor model i2t monitoring" function must be activated in the converter.

Note

Connector for temperature sensors

The temperature sensor is connected to the signal connector together with the speed encoder

signal.

1PH8 motors without an encoder can only be ordered as induction motors. In this case, the

temperature sensor is connected to the signal terminal strip in the terminal box. An additional

M16 x 1.5 cable entry is provided in the terminal box to establish a connection. For encoderless

1PH8 motors connected using a connector, the temperature sensor is connected to the encoder

connector (connector version and assignment the same as for HTL encoders).

The spare temperature sensor (option A25 for shaft heights 80 to 160) and the circuit of PTC

thermistors for alarm/trip (option A12) are connected to a signal terminal block in the terminal

box.

5.1.2 Encoder

5.1.2.1 Encoder overview

The encoder is encrypted at the 9th position of the motor Article number using the appropriate

letters.

Note

Dierent encoder types for motors with or without DRIVE-CLiQ

The identication letters at the 9th position of the Article No. for the encoder type required is

dierent for motors with and without DRIVE-CLiQ.

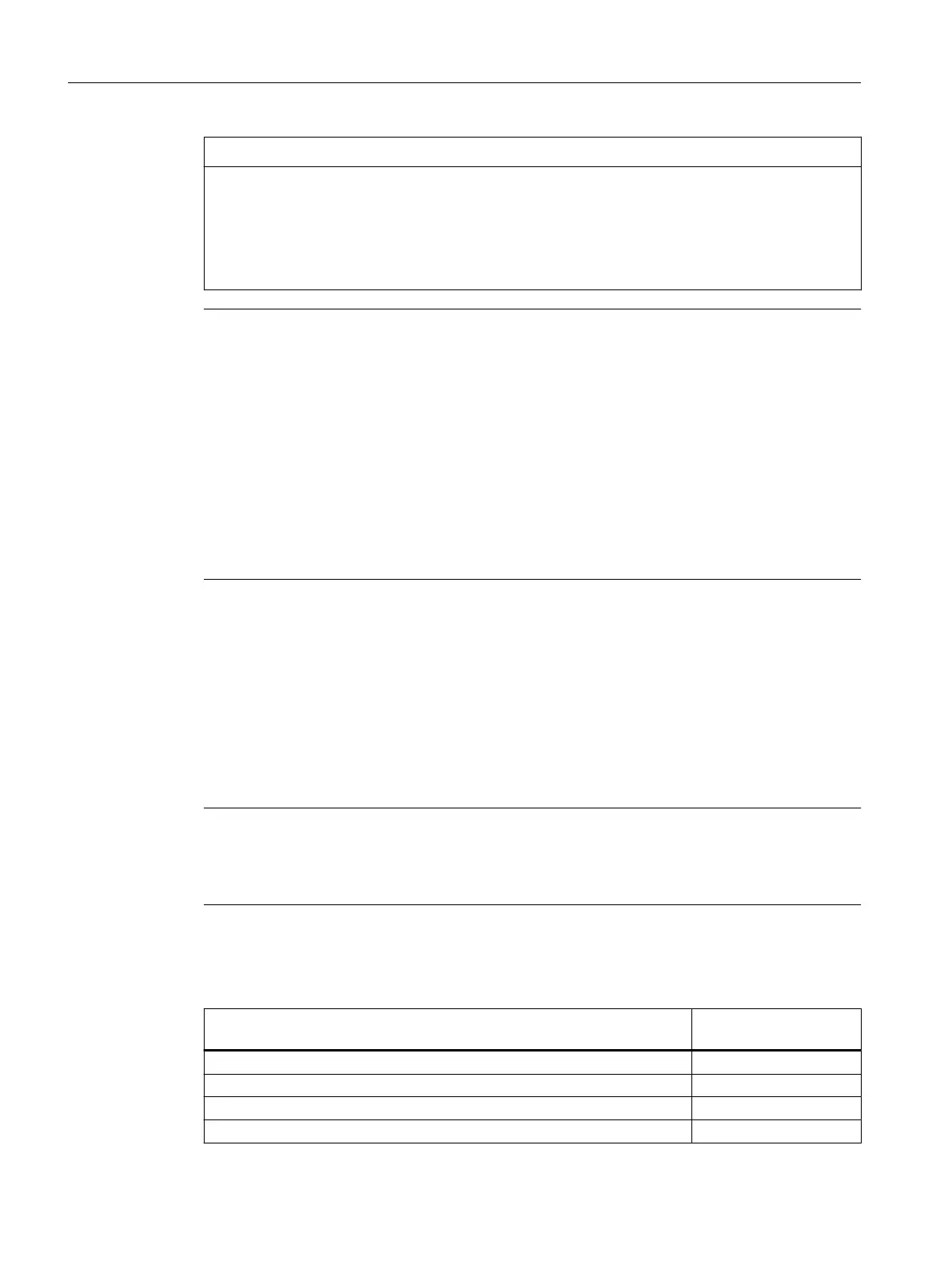

Table 5-2 Encoder types for motors without DRIVE-CLiQ

Encoder type 9th position of the Arti‐

cle No.

Without encoder A

Absolute encoder EnDat 2048 S/R (encoder AM2048S/R) E

Incremental encoder HTL 1024 S/R (encoder HTL 1024 S/R) H

Incremental encoder HTL 2048 S/R (encoder HTL 2048 S/R) J

Motor components and options

5.1Motor components

1PH8 SIMOTICS M main motors

158 Conguration Manual, 12/2022, A5E51895839A

Loading...

Loading...