1PH822x-1Ax10-xxx1-Z, Z=L03

1PH822x-1Ex00-xxx1-Z, Z=L03

1PH822x-1Ex10-xxx1-Z, Z=L03

1PH822x-1Hx00-xxx1-Z, Z=L03

1PH822x-1Hx10-xxx1-Z, Z=L03

1PH822x-1Jx00-xxx1-Z, Z=L03

1PH822x-1Jx10-xxx1-Z, Z=L03

1PH822x-1Mx00-xxx1-Z, Z=L03

1PH822x-1Mx10-xxx1-Z, Z=L03

1PH822x-2Ex00-xxx1-Z, Z=L03

1PH822x-2Ex10-xxx1-Z, Z=L03

1PH822x-2Mx00-xxx1-Z, Z=L03

1PH822x-2Mx10-xxx1-Z, Z=L03

Operating conditions of shaft heights 180 and 225

The vibration load that is permissible by default for the 1PH8 main motors is described in Chapter

"Vibration response." Take the maximum permissible vibration acceleration rates in conjunction

with option L03 from the following table:

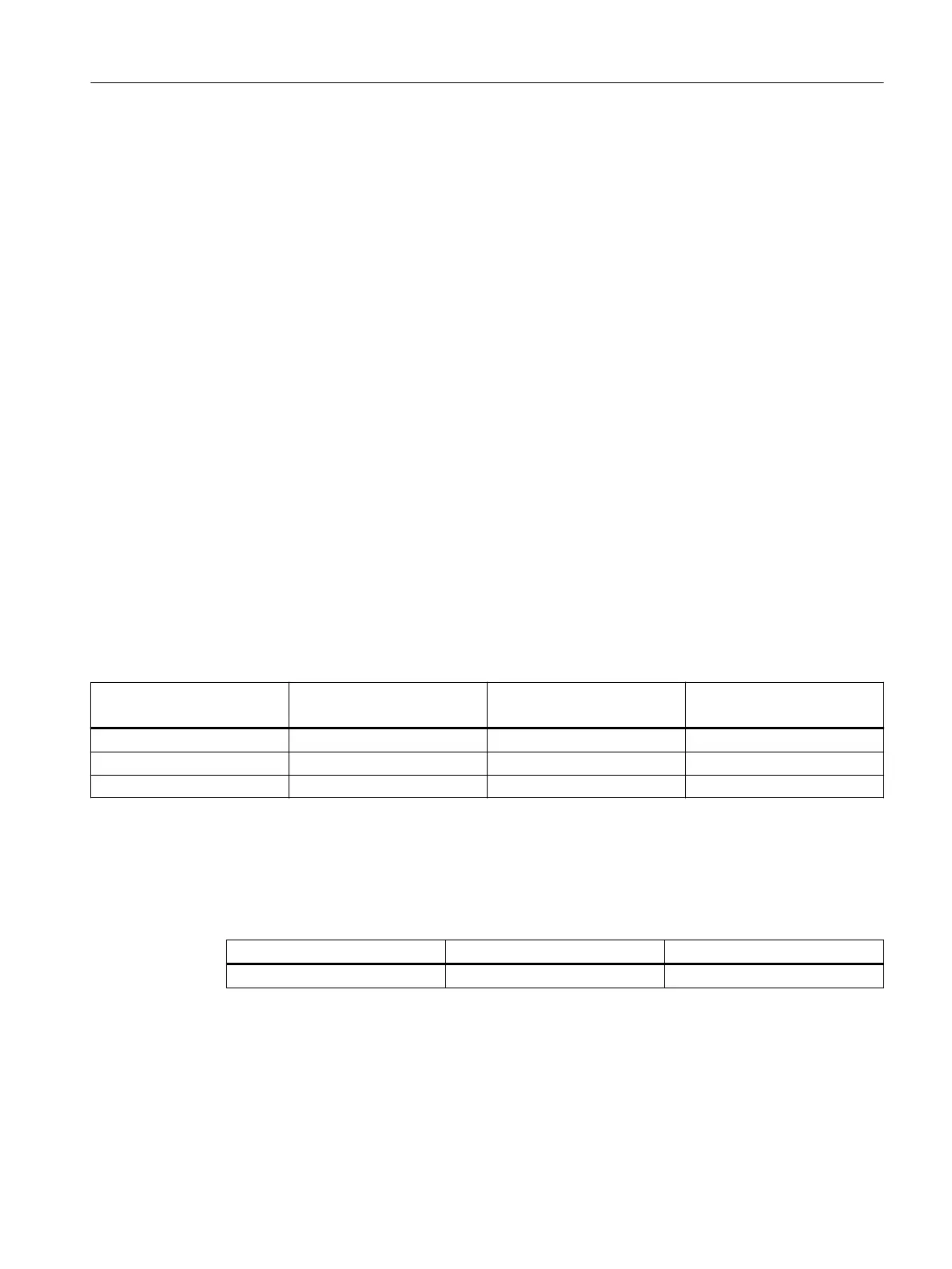

Table 5-14 Maximum permissible vibration accelerations

Standard

SH 180 and SH 225

Option L03

SH 180

Option L03

SH 225

Vertical 1.0g 4.0g 3.5g

Horizontal 1.0g 3.5g 3.2g

Axial 1.0g 3.5g 3.2g

Vibration acceleration rates (0peak) in the frequency range from 0Hz to 1kHz at the

bearings must not exceed the values listed in the table. The position of the measuring points

is dened in ISO10816-1. The customer must pin the 1PH8 motor at the DE and NDE using

a cylindrical grooved pin according to ISO 8740. To do this, place the motor down on a metal

foundation. For easier removal, do not use blind holes in the foundation for the pinning.

Recommendation: Through holes for pressing through the cylindrical grooved pins.

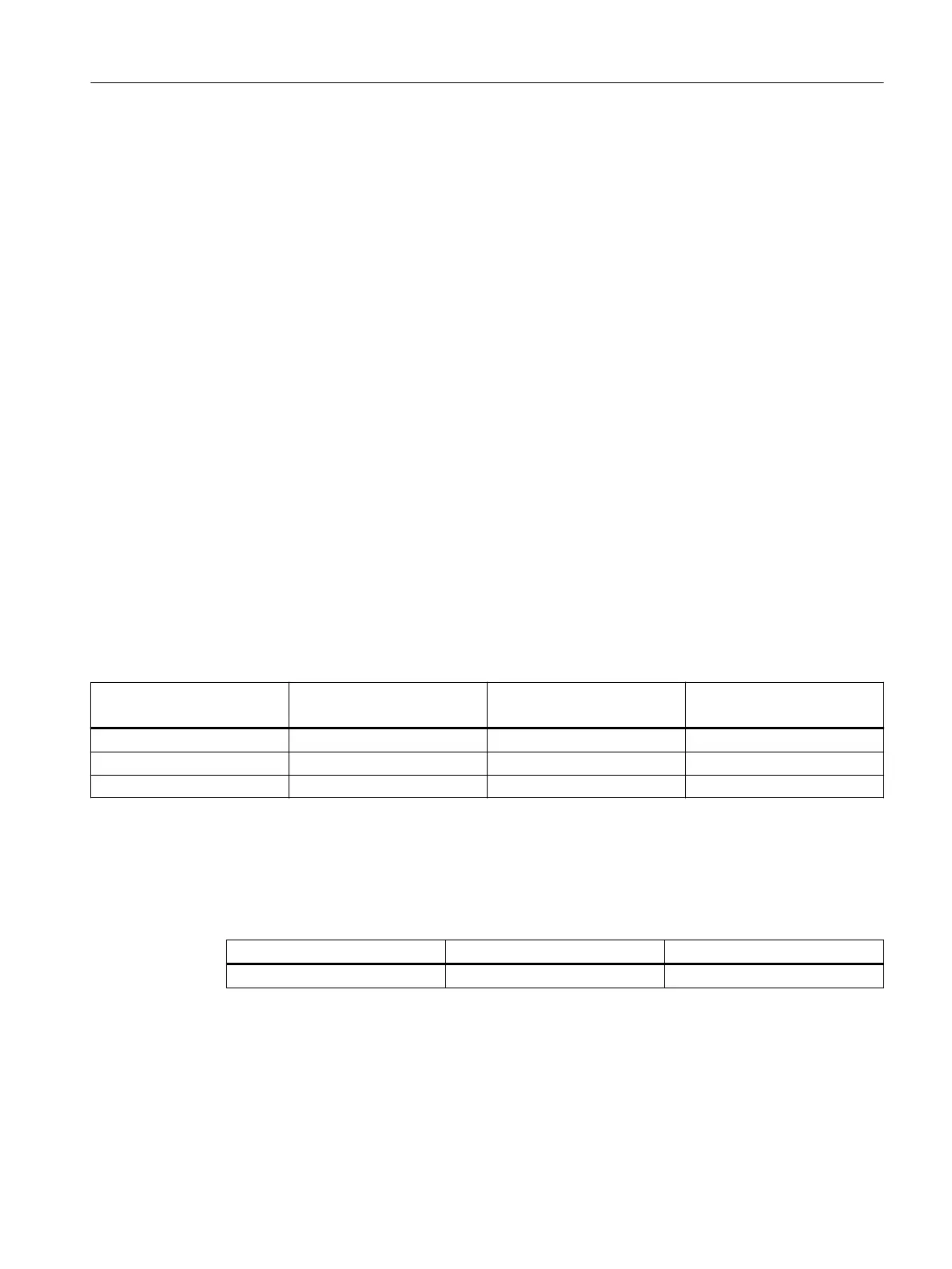

Grooved pins acc. to ISO 8740 SH 180 SH 225

Grooved pin diameter 5mm 6mm

Measures included

• Reinforced version of a DE bearing shield

• Fan unit (EC fan) with upgraded electronic components

• Screws locked with Loctite 270

Motor components and options

5.2Options

1PH8 SIMOTICS M main motors

Conguration Manual, 12/2022, A5E51895839A 179

Loading...

Loading...