Formula symbol Unit Description

t

1

... t

n

% Time percentage of the bearing load

n

1

... n

n

r/min Operating speed

You therefore calculate an average speed from the dierent speeds according to their time

percentages.

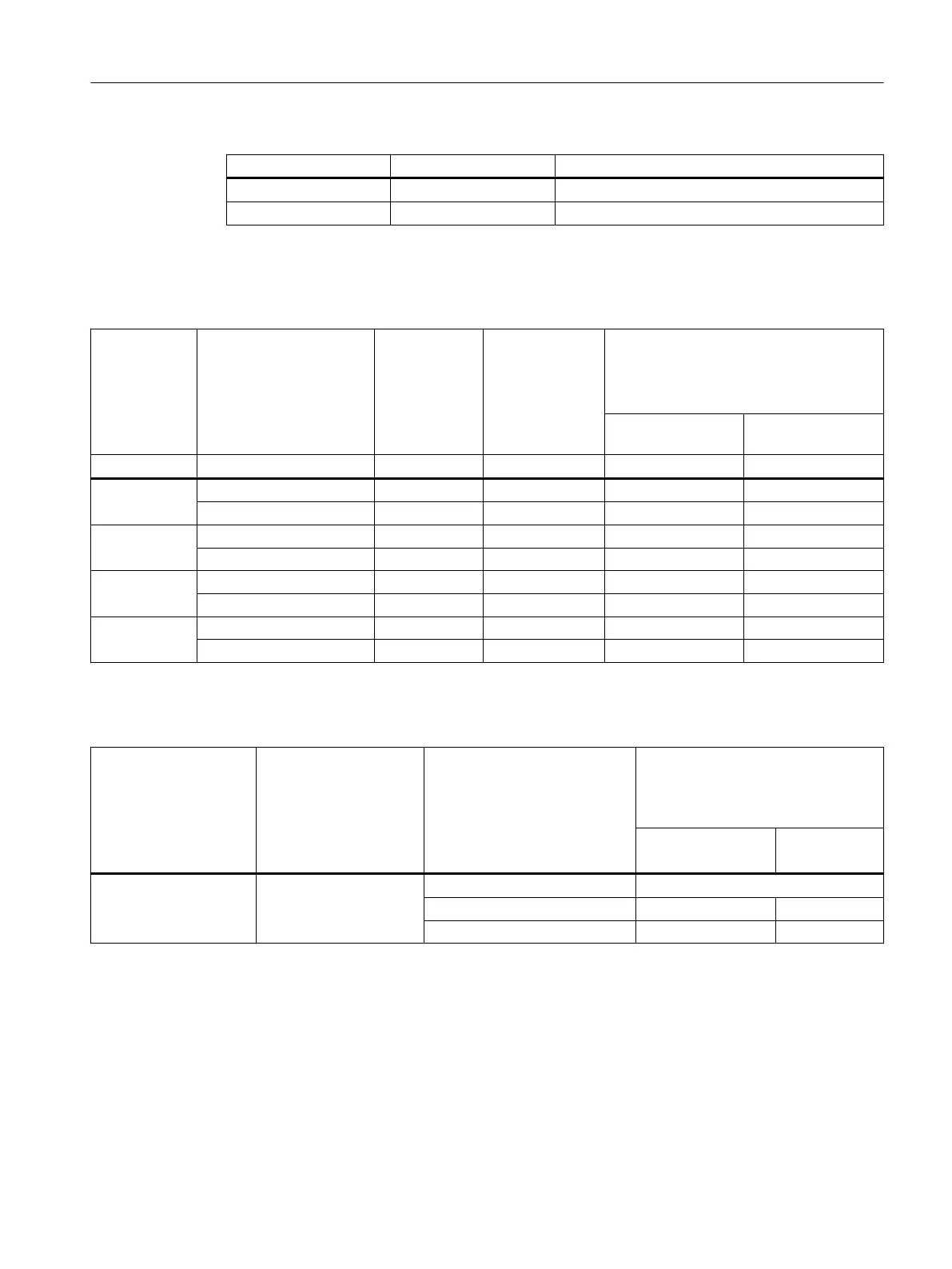

Table 4-17 Recommended bearing change intervals at maximum speed

Shaft height Bearing version Maximum

speed

n

max

r/min

Statistical

bearing

service life

L

10h

h

Recommended bearing replacement in‐

terval

t

LW

h

Permanent lubrica‐

tion

Relubrication

80 Performance 15,000 8000 8000 -

High Performance 20,000 8000 8000 -

100 Performance 12,000 8000 8000 -

High Performance 18,000 8000 8000 -

132 Performance 10,000 8000 8000 -

High Performance 15,000 8000 8000 -

160 Performance 9000 8000 8000 -

High Performance 10,000 8000 8000 -

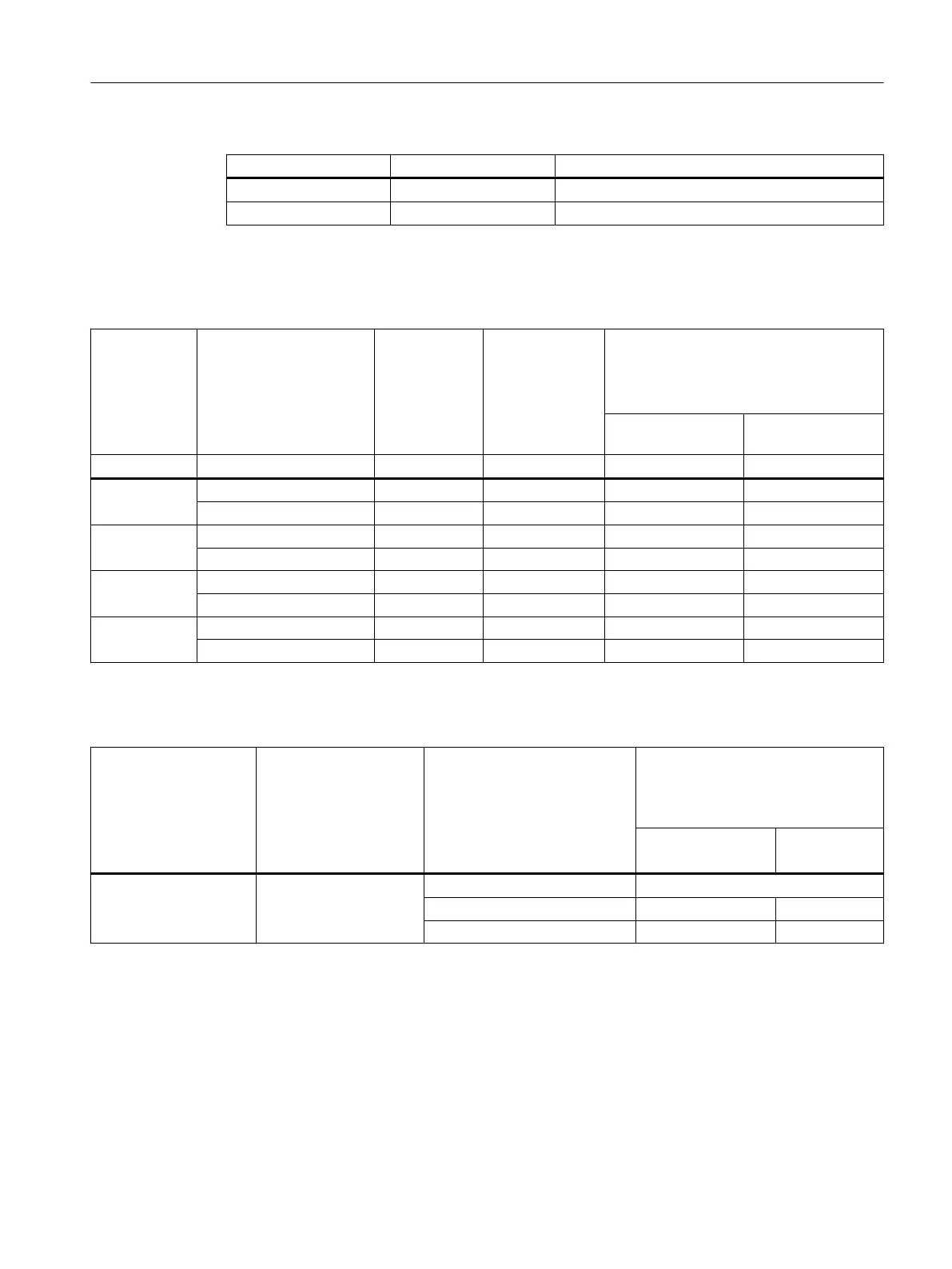

Table 4-18 "Premium Performance" bearing version, maximum speed and bearing change intervals

Shaft height Maximum speed

n

max

r/min

Average operating speed

n

m

r/min

Recommended bearing replace‐

ment interval

t

LW

h

with sealing air

(Option Q12)

without seal‐

ing air

80 24,000 <16,000 12,000

<19,200* 10,000 8000

24,000 7000 4000

Speed backlash with:

t1=10min, n1=0

t2=30min, n2=16,000r/min

t3=60min, n3=24,000r/min

Mechanical properties

4.4Types of bearing

1PH8 SIMOTICS M main motors

Conguration Manual, 12/2022, A5E51895839A 89

Loading...

Loading...