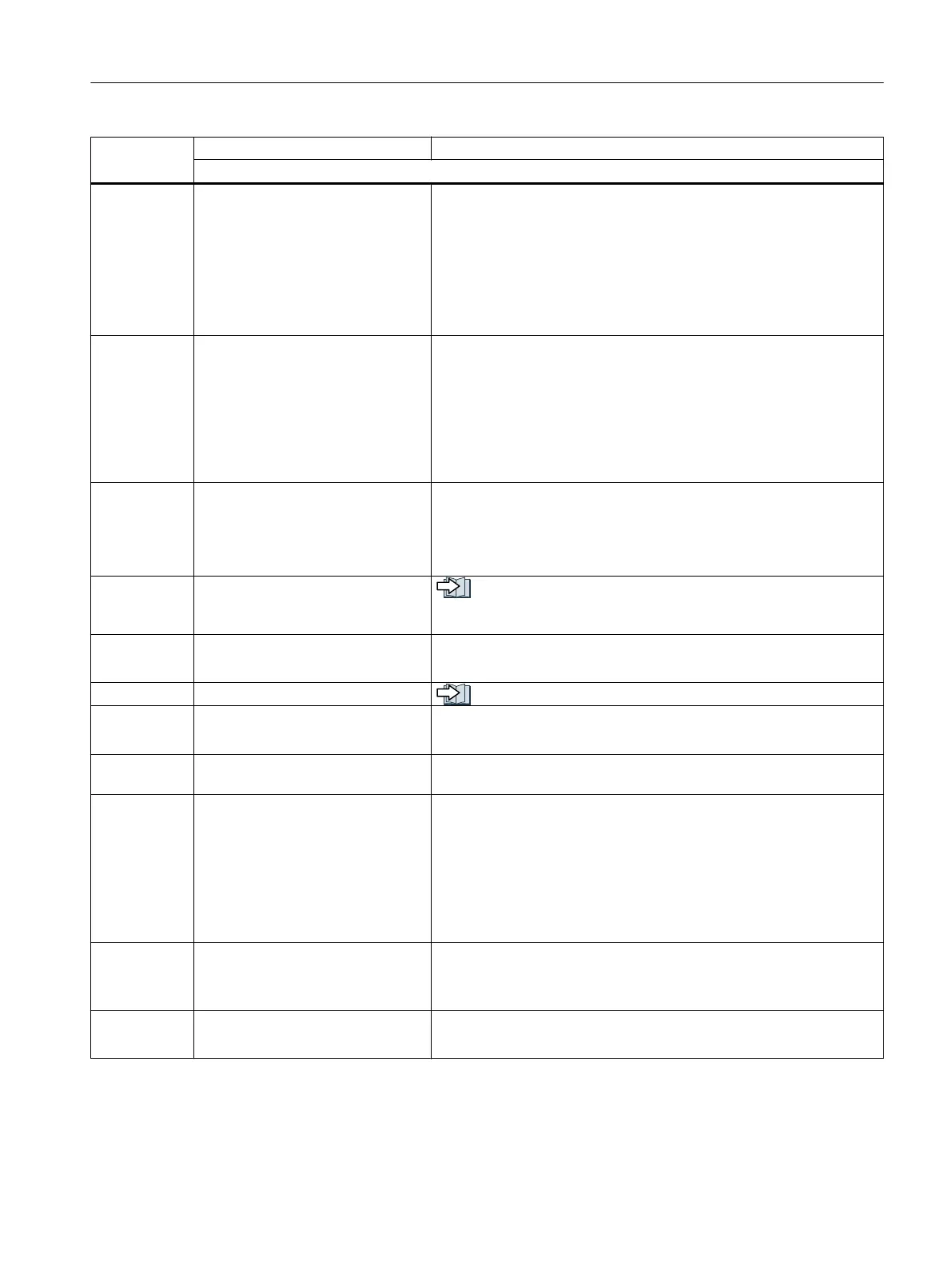

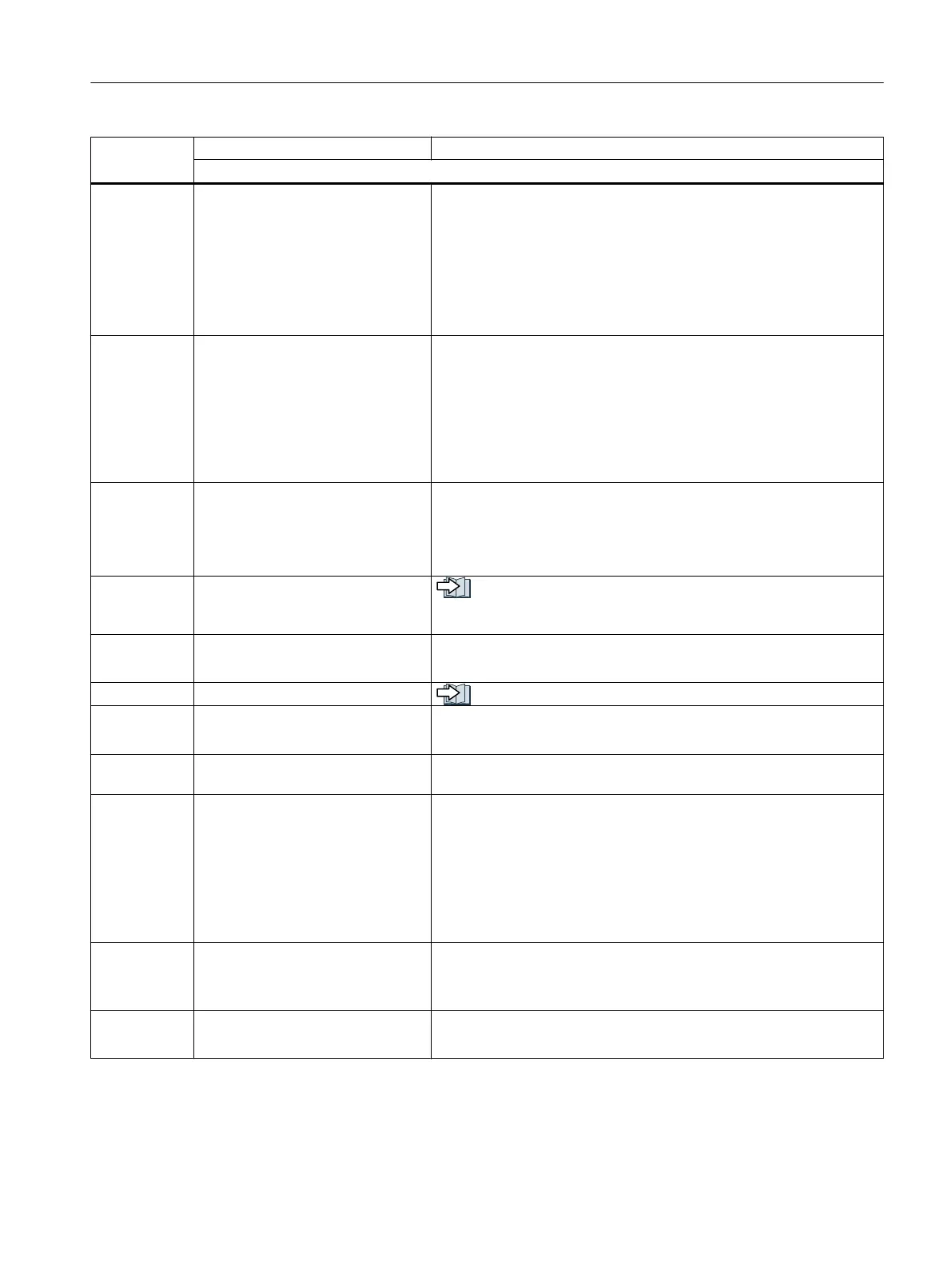

Signal Cause Remedy

Complete information on the messages is available in the List Manual.

F01625 Sign-of-life error in the Safety data Check that the control cabinet design and cable routing are both in

compliance with EMC regulations.

Check as to whether an inadmissible voltage, e.g. 230 V, is connected

at the Control Unit digital output.

Fault acknowledgment

1. Select STO, and then deselect again.

2. If it cannot be acknowledged, replace the Control Unit.

F01630 Brake control defective

Fault value r0949 provides more de‐

tailed information.

Depending on the fault value, check the following:

10, 11: p1278 ≠ 0, brake not connected, cable interrupted or ground

fault

20: Short-circuit in the brake winding

30, 31, 40: Brake not connected or a short-circuit in the brake winding

50: Fault in the Safe Brake Relay, in the Control Unit or in the Power

Module.

A01631 Motor holding brake / SBC configu‐

ration does not make sense

Check and correct the parameterization of the motor holding brake:

The following settings can result in this message:

● p1215 = 0 and p9602 = 1.

● p1215 = 3 and p9602 = 1.

F01640,

F01641

It has been identified that a compo‐

nent has been replaced, acknowl‐

edgment/data save is necessary

Corrective maintenance (Page 331)

F01649 Internal software error

1. Switch off the Control Unit power supply and then on again.

2. If it cannot be acknowledged, replace the Control Unit.

F01650 Acceptance test required Acceptance tests for the safety functions (Page 209)

F01651 Synchronization, safety time slices

unsuccessful.

1. Switch off the Control Unit power supply and then on again.

2. If it cannot be acknowledged, replace the Control Unit.

F01653 PROFIBUS/PROFINET configura‐

tion error

Check the PROFIBUS or PROFINET configuration of the safety slot

on the master side and on the Control Unit.

A01654 PROFIBUS configuration differs Check the PROFIsafe configuring in the higher-level control.

● Alarm value r2124 = 1:

In the higher-level F control, remove the PROFIsafe configuring,

or enable PROFIsafe in the drive.

● Alarm value r2124 = 2:

In the higher-level F control, configure the appropriate PROFIsafe

telegram.

F01655 Aligning the monitoring functions

1. Check that the control cabinet design and cable routing are in

compliance with EMC regulations.

2. Switch off the Control Unit power supply and then on again.

F01656 Parameter processor 2 incorrect

1. Recommission the safety functions.

2. If this is not successful, then replace the Control Unit.

Operation

6.14 List of alarms and faults

Safety Integrated - SINAMICS G110M, G120, G120C, G120D and SIMATIC ET 200pro FC-2

Function Manual, 01/2017, FW V4.7 SP6, A5E34261271B AD 323

Loading...

Loading...