Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

101

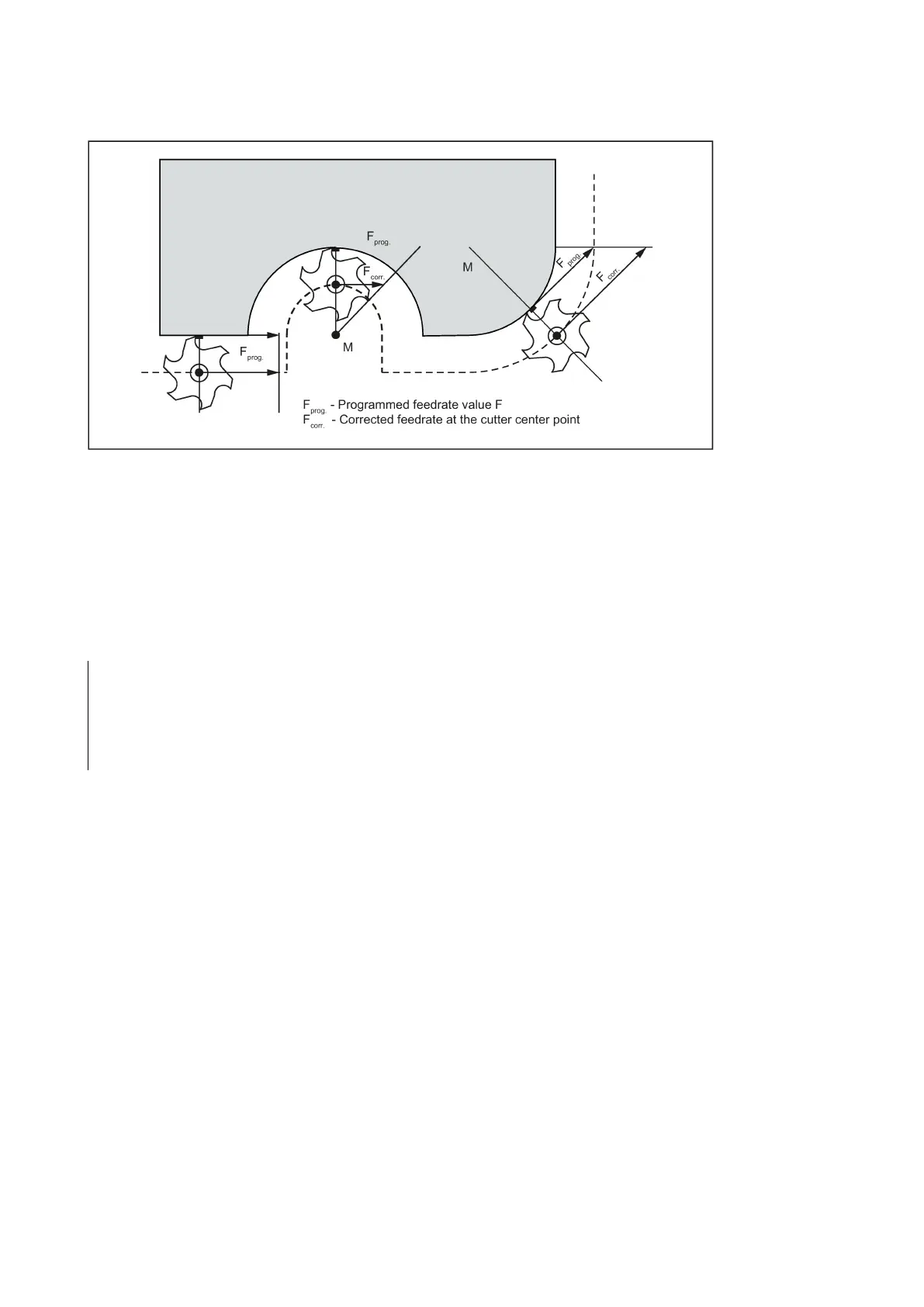

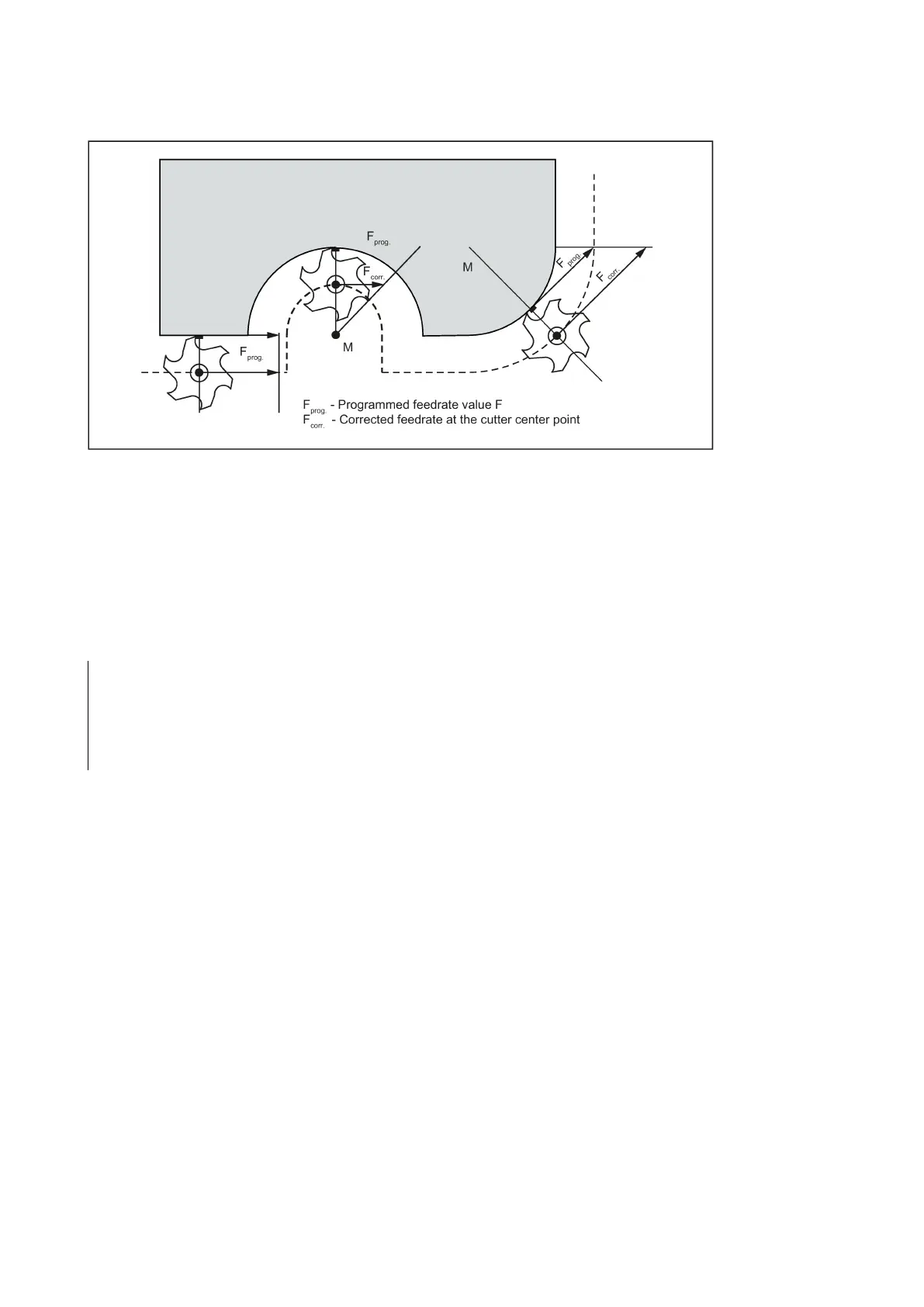

See the following illustration for feedrate override G901 with internal/external machining:

● External machining:

F

corr.

= F

prog.

(r

cont

+ r

tool

) / r

cont

● Internal machining:

F

korr.

= F

prog.

(r

cont

- r

tool

) / r

cont

r

cont

: Radius of the circle contour

r

tool

: Tool radius

; Tool radius compensation ON

; Feedrate override with circle ON

N30 G2 X50 Y40 I10 J-7 F350

; Feed value acts on cont our

N40 G3 X70 Y40 I10 J6 F300

; Feed value acts on cont our

; Feedrate override OFF, programmed fe edrate value acts at the

milling cutter center point

Thread cutting with constant lead: G33

Fu n ctionality

This requires a spindle with position measuring system.

The function G33 can be used to machine threads with constant lead of the following type: If an appropriate tool is used,

tapping with compensating chuck is possible.

The compensating chuck compensates the resulting path differences to a certain limited degree.

The drilling depth is specified by specifying one of the axes X, Y or Z; the thread pitch is specified via the relevant I, J or K.

G33 remains active until canceled by another instruction from this G group (G0, G1, G2, G3...).

Right-hand or left-hand thread

Right-hand or left-hand thread is set with the rotation direction of the spindle (M3 right (CW), M4 left (CCW) - see Section

"Spindle movements (Page 109)"). To do this, the rotation value must be programmed under address S or a rotation speed

must be set.

Loading...

Loading...