Programming and Operating Manual (Milling)

40 6FC5398-4DP10-0BA6, 09/2017

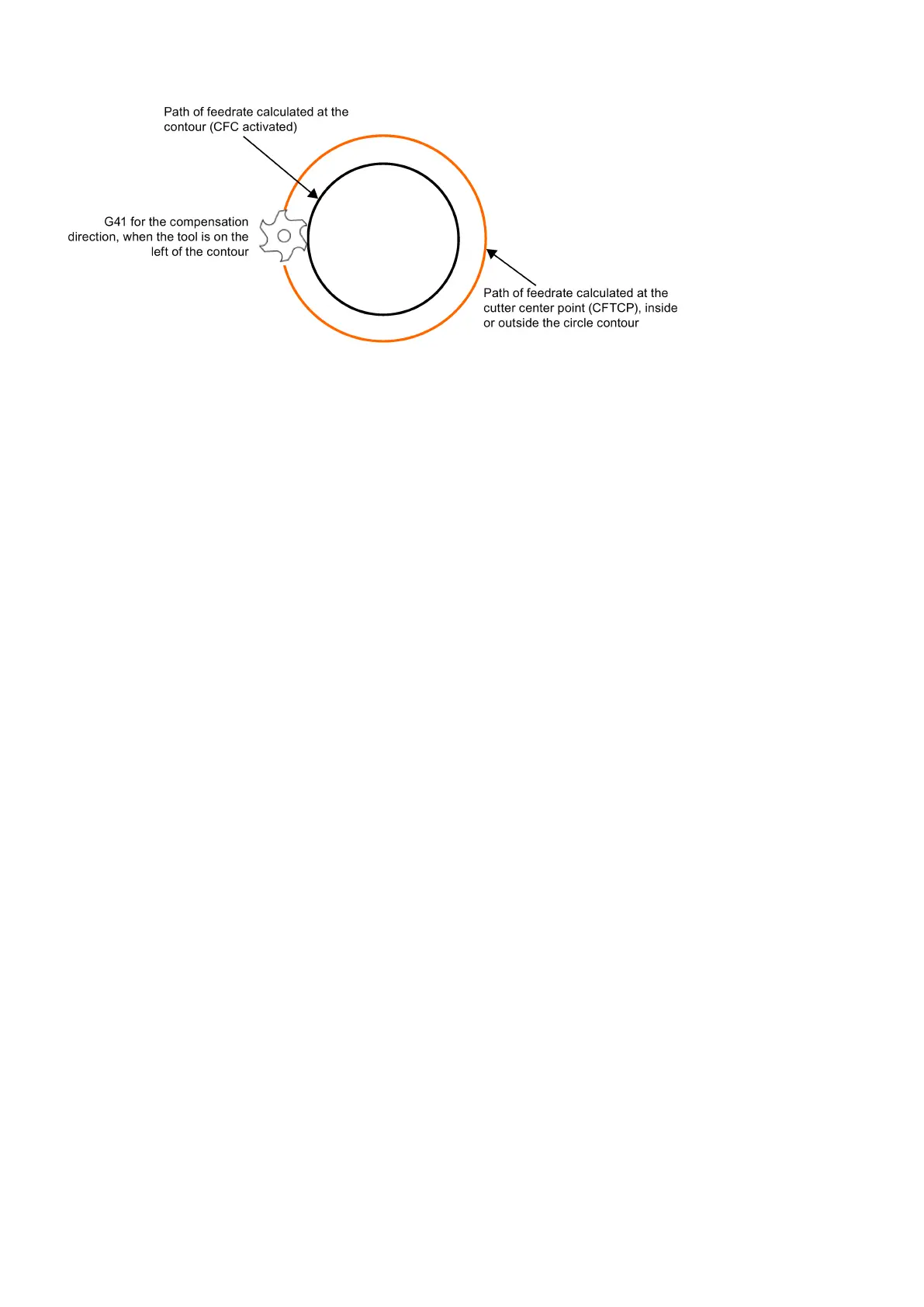

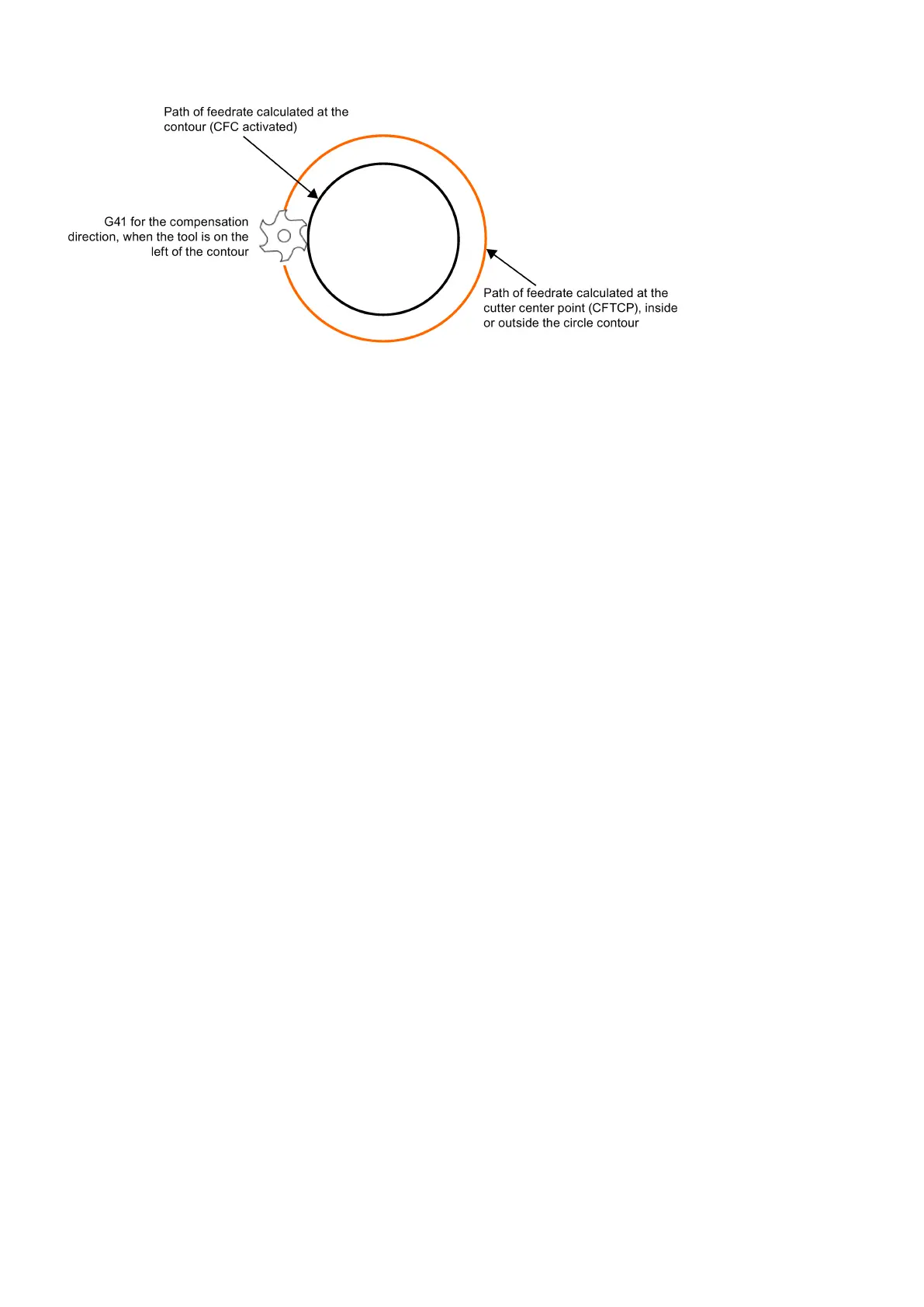

These two commands may cause the cutter to traverse fast around a corner or slowly at the contour.

For more information, see Sections "Tool radius compensation OFF: G40 (Page 122)" and "Selecting the tool radius

compensation: G41, G42 (Page 119)".

Milling circles and arcs (G02/G03)

The following gives an example of machining arc with specified program code:

N10 G17 G90 G500 G71

N20 T1 D1 M6

N30 S5000 M3 G94 F300

N40 G00 X-20 Y-20 Z5

N50 G01 Z-5

N60 G41 X0 Y0

N70 Y50

N80 X100

N90

N100 G01 Y0

N110 X0

N120 G40 X-20 Y-20

N130 G00 Z500 D0

* Note that N90 block as above can also be written as "N90 G02 X125 Y15 CR=37".

When milling circles and arcs, you must define the circle center point and the distance between the start point, end point,

and the center point in the relative coordinate system.

When using the XY coordinate system, the interpolation parameters I and J are available.

There are two common ways of defining circles and arcs:

● G02/G03 X... Y... I... J...

● G02/G03 X... Y... CR=...

Use positive value in CR with arcs ≤ 180°, and negative value with arcs > 180°.

Loading...

Loading...