Programming and Operating Manual (Milling)

252 6FC5398-4DP10-0BA6, 09/2017

Programming (Example 3)

Machining requirements

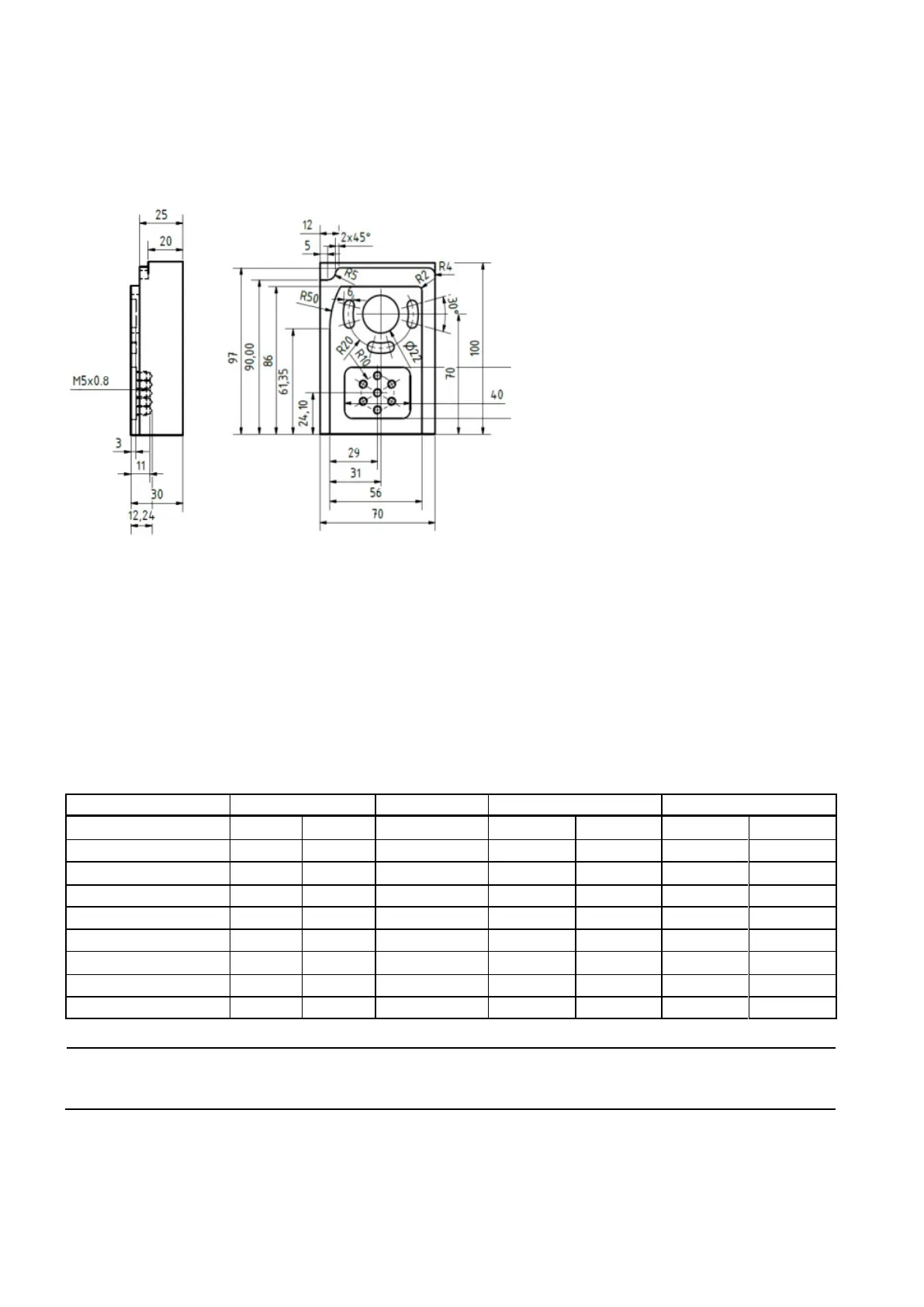

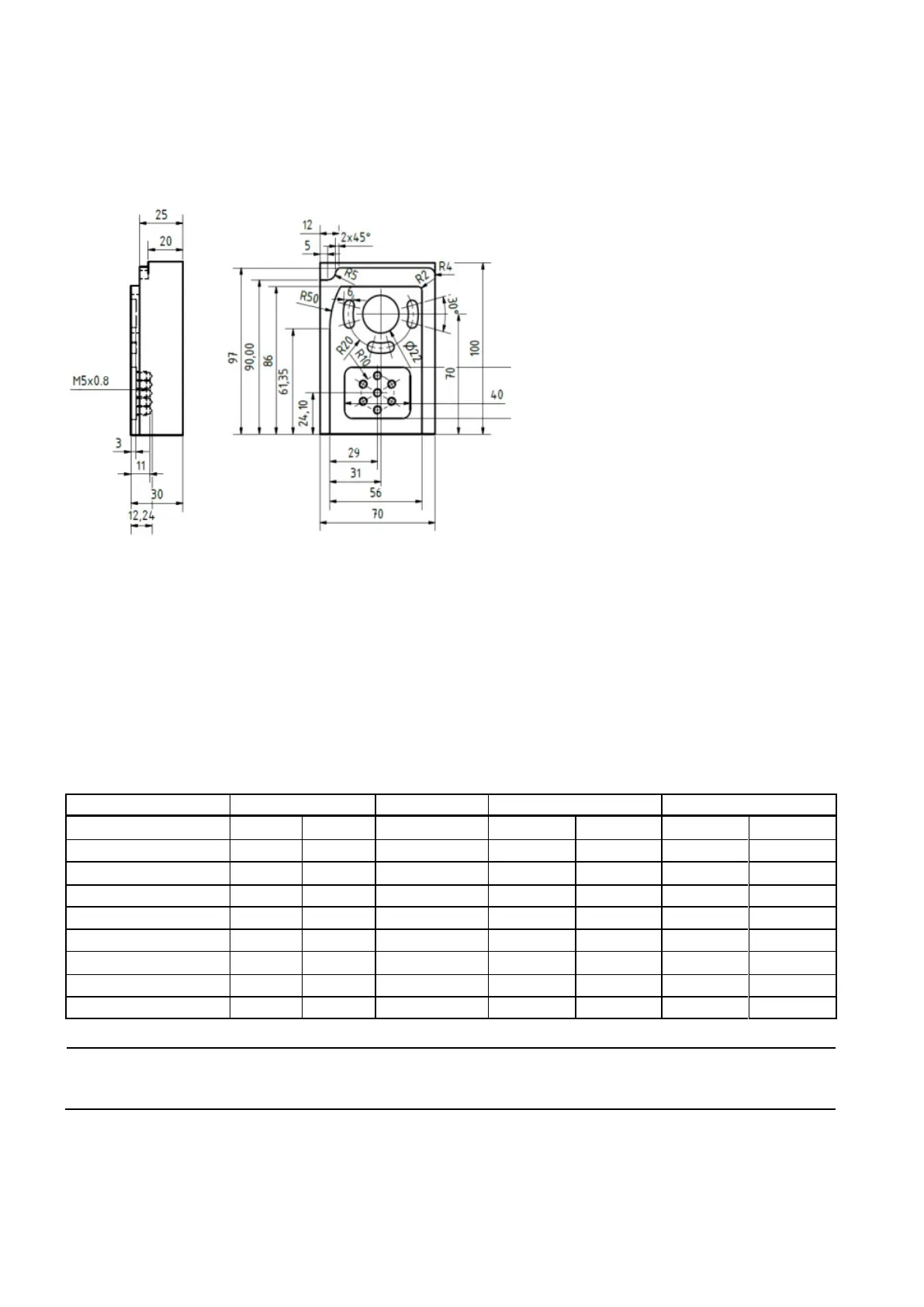

Workpiece drawing (unit: mm)

● The arc transition must be smooth, without lapping.

● The cutting trace must be even.

● The sharp edges must be rounded.

Blank material: Cube aluminum

Blank length: 100 mm

Blank width: 80 mm

Blank height: 60 mm (machining length: 46 mm; clamping length: 10 mm)

DIN ISO (mm) Speed Feedrate Speed Feedrate

End milling tool T2D1 T2H2 12 3500 600 4000 600

Drilling tool T6D1 T6H6 10 4000 100 4000 100

Drilling tool T7D1 T7H7 5 4000 100 4000 100

When programming in ISO mode, you need to set the H numbers of T1 to T8 as 1 to 8 respectively in the tool list;

• Cut the workpiece manually after machining is over.

Loading...

Loading...