Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

169

For example, to machine a center hole (in Z) in the G17 plane, you program:

G17

AXN=3

Deep-hole tapping: VARI, DAM, VRT

With the VARI parameter, it is possible to distinguish between simple tapping (VARI = 0) and deep-hole tapping (VARI ≠ 0).

In conjunction with deep-hole tapping, it is possible to choose between chip breaking (retraction by variable distance from

current drilling depth, parameter VRT, VARI = 1) and chip removal (withdrawal from reference plane VARI = 2). These

functions work analogously to the normal deep-hole drilling cycle CYCLE83.

The incremental drilling depth for one pass is specified via parameter DAM. The cycle internally calculates the intermediate

depth as follows:

● The programmed incremental drilling depth is executed in each step until the rest up to the final drilling depth is less than

(<) 2 x DAM

● The remaining drilling depth is halved and executed in two steps. Thus, the minimum drilling depth is not smaller than

DAM / 2.

Note

The direction of rotation when

tapping in the cycle is always reversed automatically.

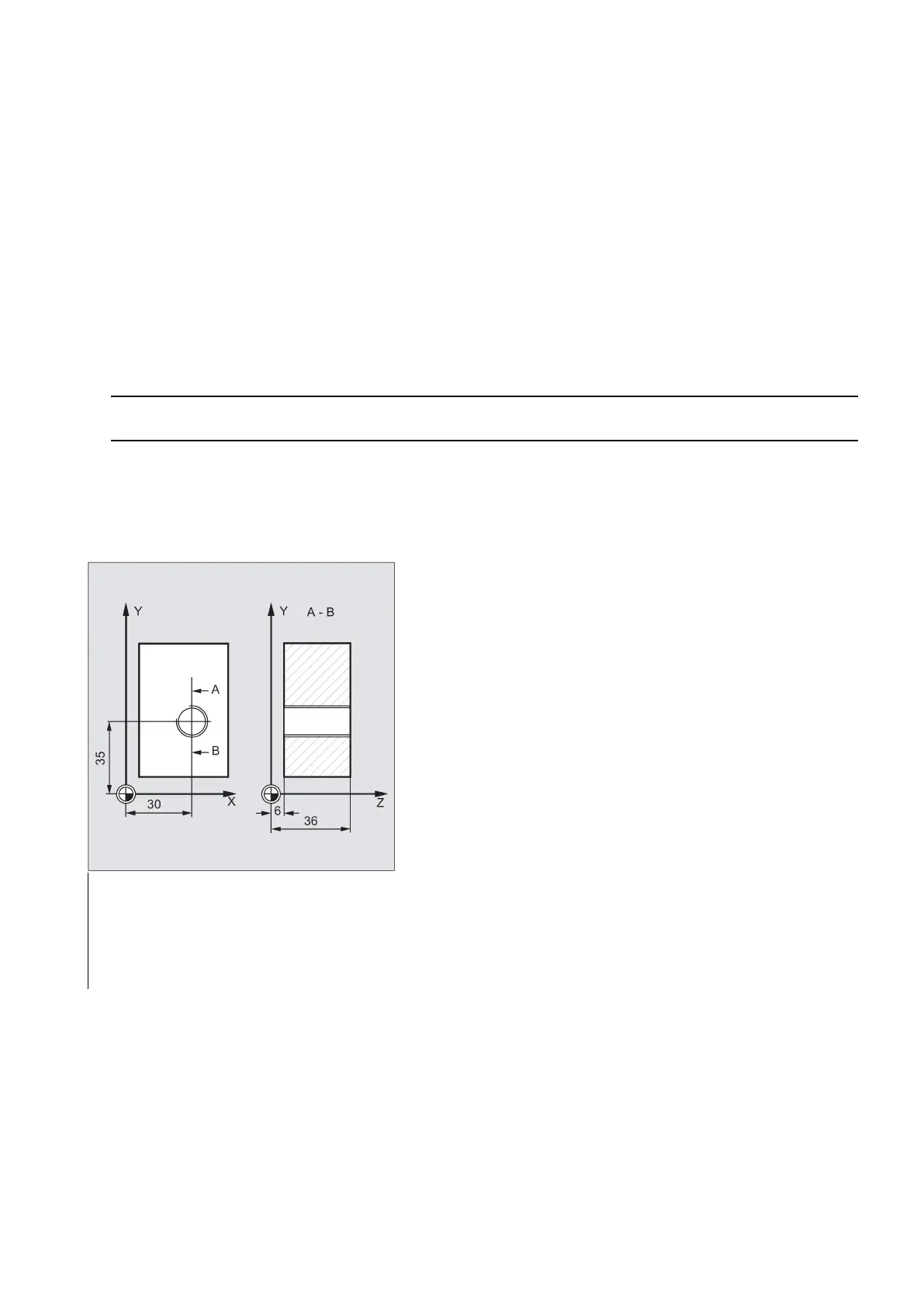

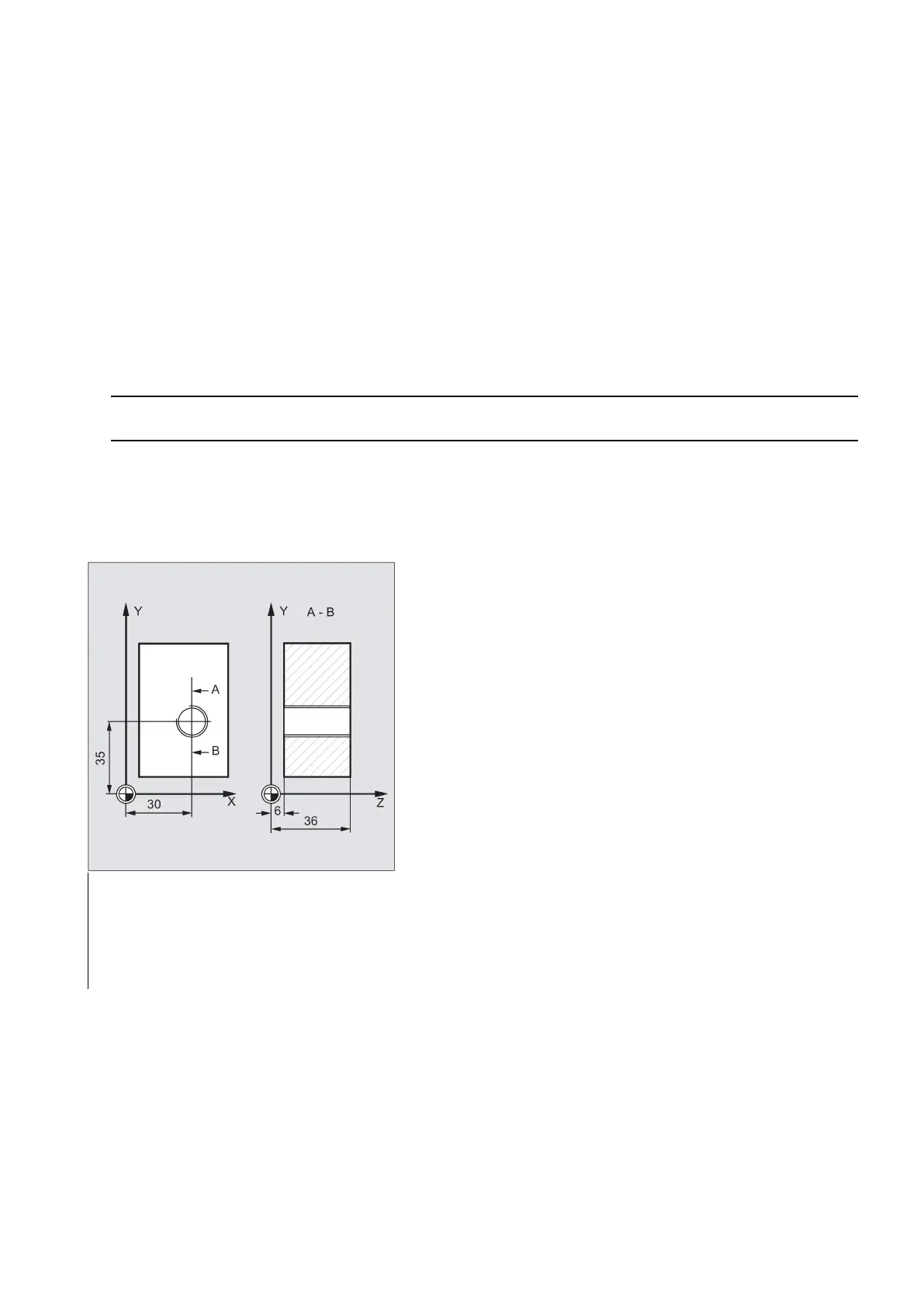

Programming example 1: Rigid tapping

A thread is tapped without compensating chuck at position X30 Y35 in the XY plane; the tapping axis is the Z axis. No dwell

time is programmed; the depth is programmed as a relative value. The parameters for the direction of rotation and for the

lead must be assigned values. A metric thread M5 is tapped.

; Specification of technology values

; Approach drilling position

N30 CYCLE84(20,0,3,-15,,1,3,6,,0,500,500,3,0,0,0,5 ,0)

Cycle call; parameter PIT has been omit-

ted; no value is entered for the absol ute

depth or the dwell time ; spindle stop at

90 degrees; speed for tapping is 200,

speed for retraction is 500

Loading...

Loading...