Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

181

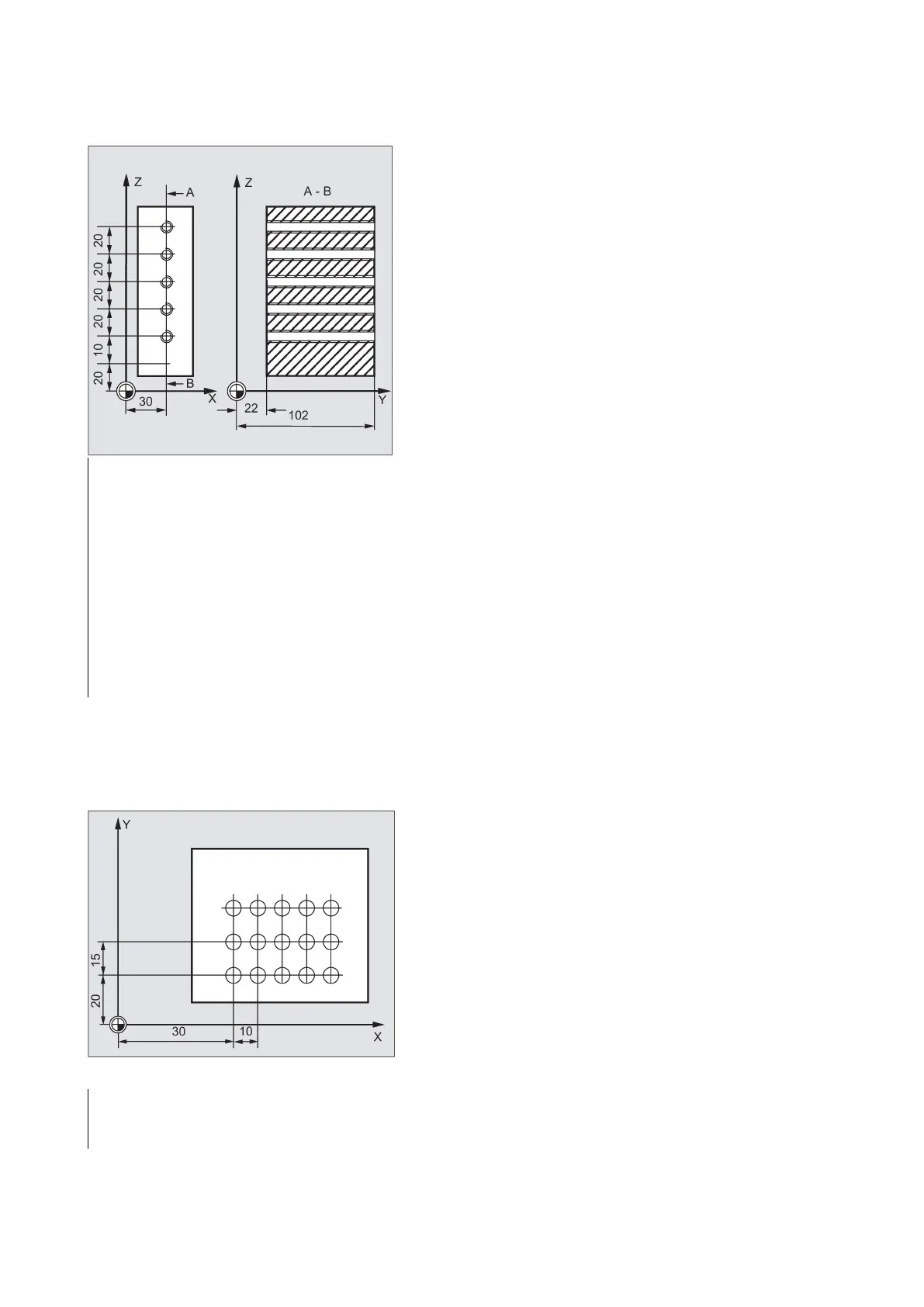

drilling is carried out using CYCLE82, and then tapping is performed using CYCLE84 (tapping without compensating chuck).

The holes are 80 mm in depth (difference between reference plane and final drilling depth).

N10 G90 F30 S500 M3 T10 D1

; Specification of the technological

values for the machining step

; Approach start position

N30 MCAL L CYCLE82( 105, 102, 2, 22, 0, 1)

; Modal cal l of drilling cycle

N40 HOLES1(20, 30, 0, 10, 20, 5)

; Call of row-of-holes cycle; the cycle

starts with the first hole; only the

drill positions are approached in this

; Approach position next to 5t h hole

N70 MCAL L CYCLE84( 105, 102, 2, 22, 0, , 3, , 4.2 , ,300, )

; Modal cal l of the tappi ng cycle

N80 HOLES1(20, 30, 0, 10, 20, 5)

; Call of row of holes cycle starting

with the fifth hole in the row

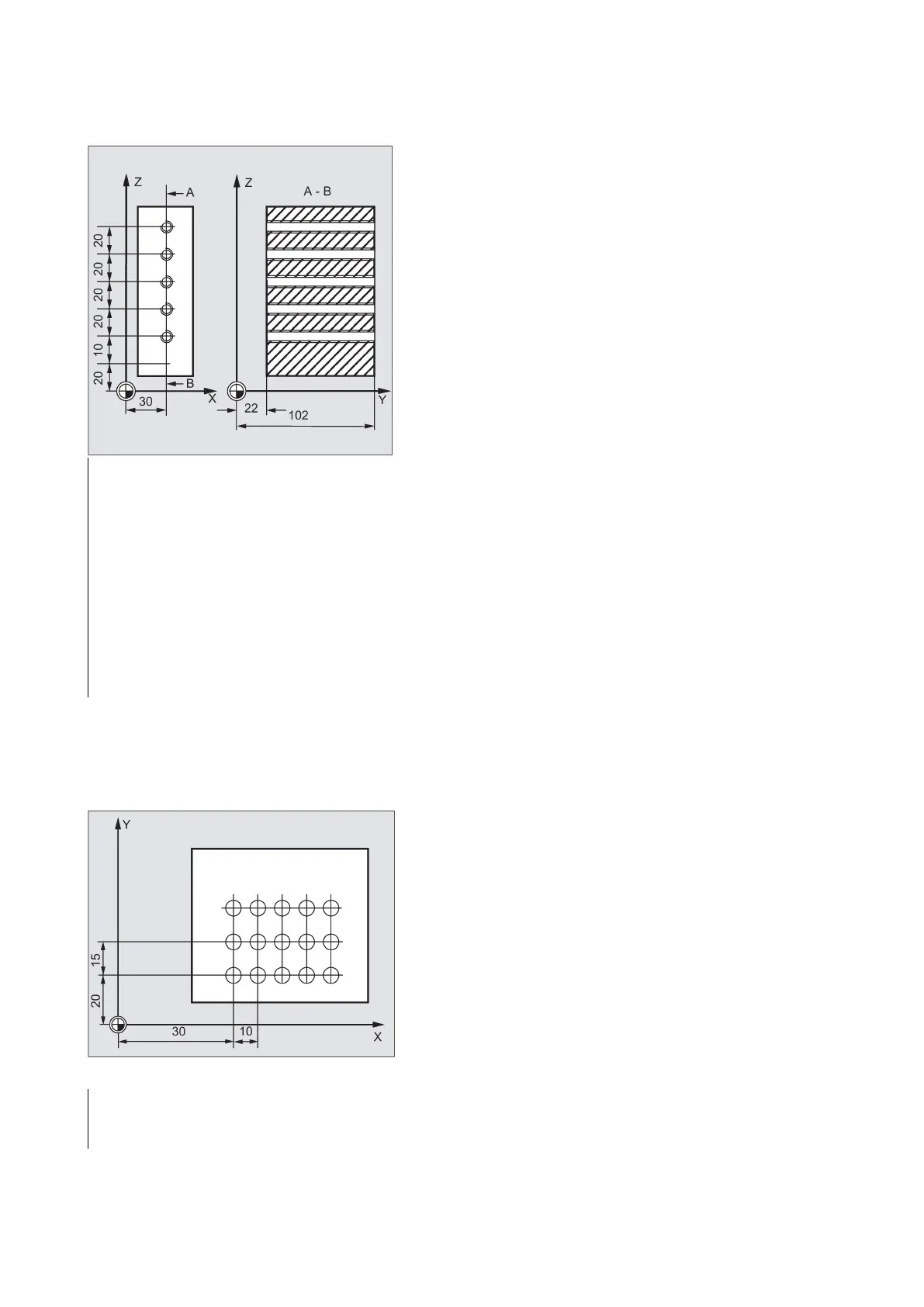

Programming example: Grid of holes

Use this program to machine a grid of holes consisting of five rows with five holes each, which are arranged in the XY plane,

with a spacing of 10 mm between them. The starting point of the grid is at X30 Y20.

The example uses R parameters as transfer parameters for the cycle.

R11=105

R12=2

; Retraction plane

; Safety clearance

Loading...

Loading...